Derrick Steel Structure Damage Identification Method Based on IMF Instantaneous Energy Curvature Difference

A technology for instantaneous energy and damage identification, applied in the field of signal processing, can solve the problem of difficulty in obtaining high-order modal parameters of large and complex steel structures, and achieve good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing:

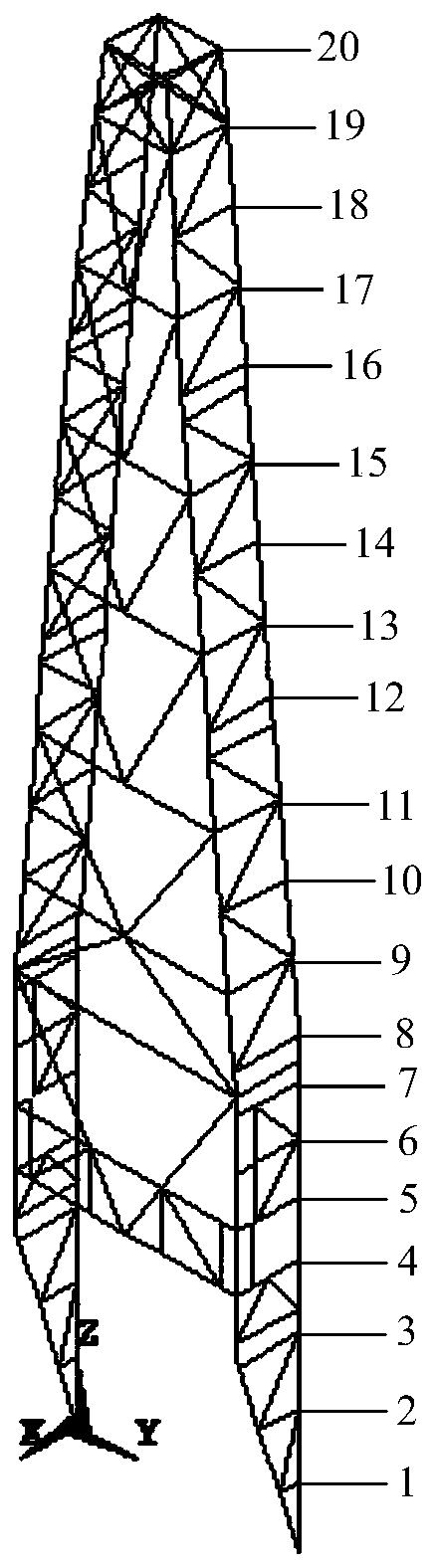

[0054] The derrick steel structure finite element model that the present invention adopts is as figure 2 As shown, the main nodes of the right front column of the model are nodes 1 to 20 from bottom to top. Assuming that there is a unit between the two nodes, they are divided into units 1 to 19 from bottom to top.

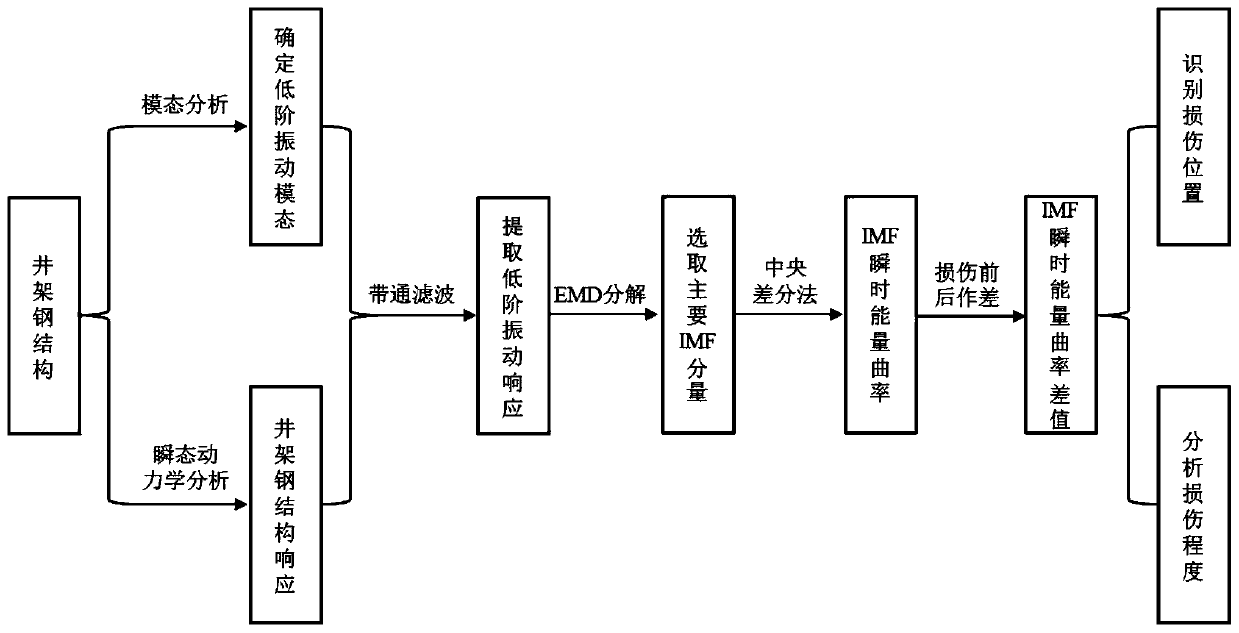

[0055] Such as figure 1 Shown, method of the present invention comprises the following steps:

[0056] Step 1. Perform modal analysis on the derrick steel structure to determine the low-order vibration mode of the derrick steel structure, and perform transient dynamic analysis on the derrick steel structure to extract the vibration responses of different parts;

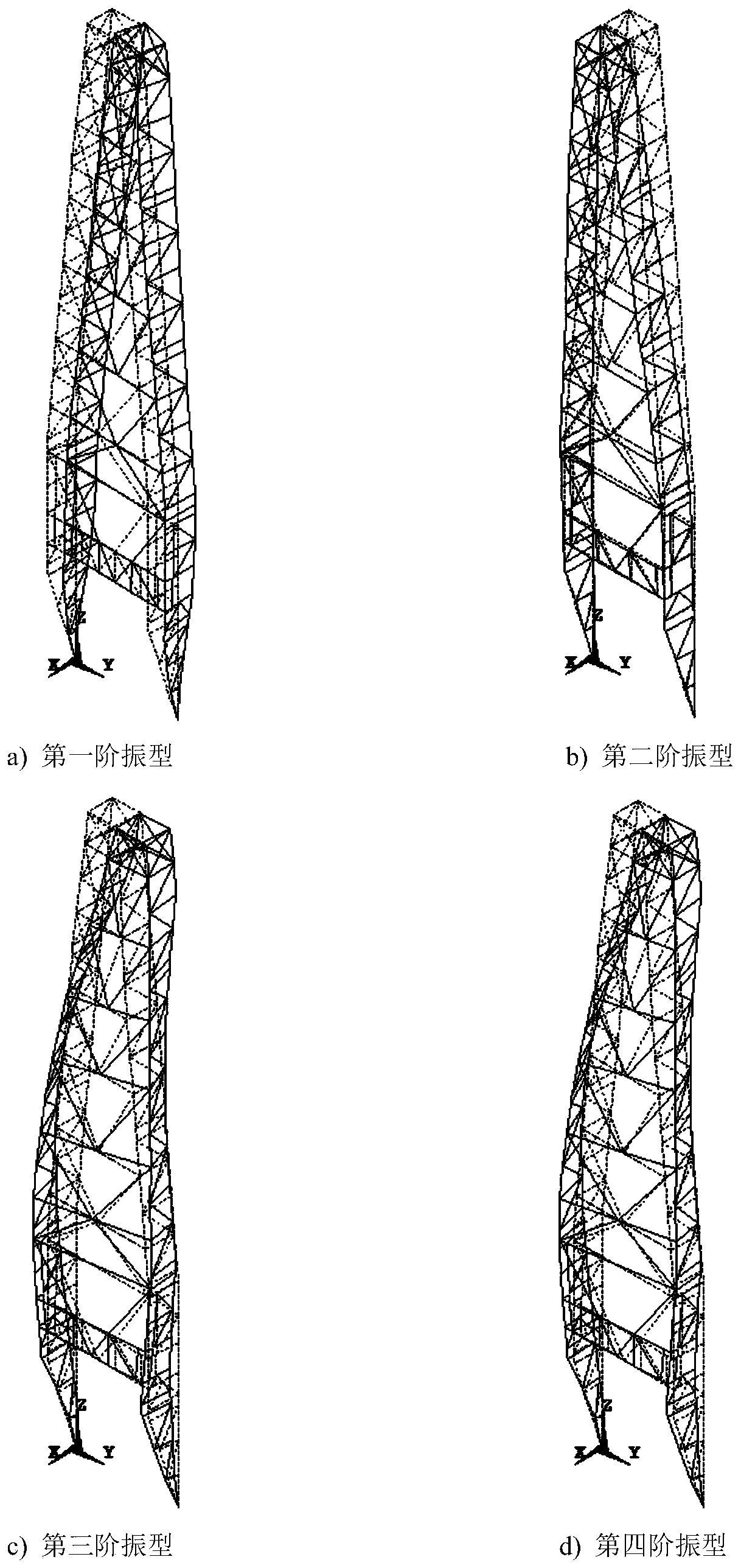

[0057] The modal analysis is carried out on the steel structure of the derrick, and the vibration shapes and frequencies of the first 4 orders of the model are extracted. Such as image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com