Mixed storage chemical freight van management method and server

A technology for managing servers and management methods, which is applied in the direction of instruments, data processing applications, and collaborative operation devices, etc., which can solve the problems of hidden safety hazards in chemicals and low efficiency of manual management, and achieve convenient automation, safety assurance, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

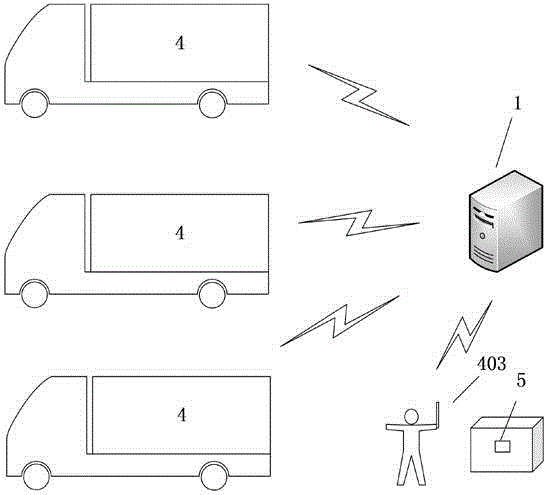

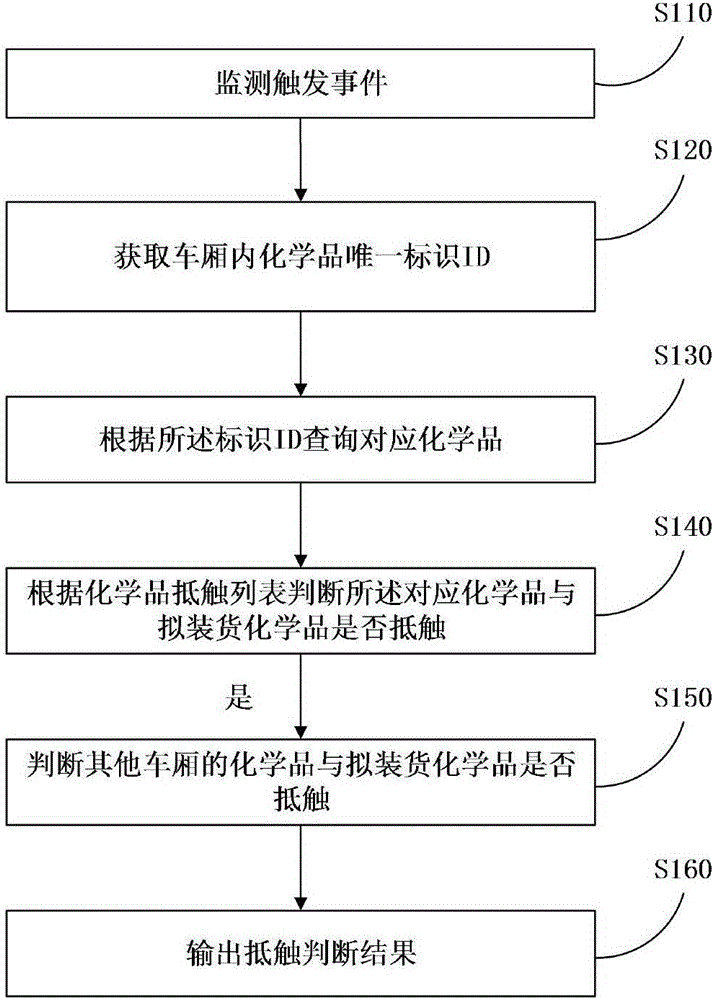

[0069] Such as figure 1 As shown, the present embodiment provides a freight compartment management method for mixing chemicals, and the method includes:

[0070] S110: monitor a trigger event;

[0071] S120: When a trigger event occurs, obtain the unique ID of the chemical in the compartment;

[0072] S130: Query corresponding chemicals according to the identification ID;

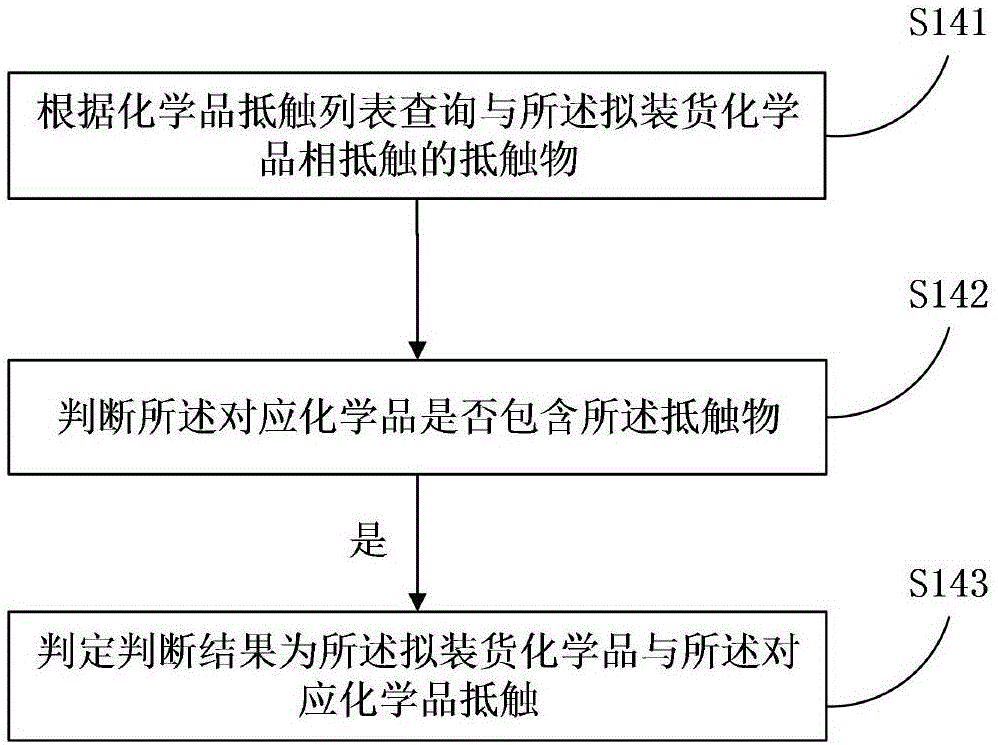

[0073] S140: Determine whether the corresponding chemical conflicts with the chemical to be loaded according to the chemical conflict list, and the chemical to be loaded is a chemical to be loaded into the compartment;

[0074] S150: If the conflict determination result is yes, determine whether the chemicals in other compartments conflict with the chemicals to be loaded;

[0075] S160: Output a conflict judgment result.

[0076] In the process of specific implementation, before the step of monitoring the triggering event, it includes:

[0077] Set the trigger event;

[0078] When implemented, the tri...

Embodiment 2

[0111] Such as Figure 4 As shown, according to yet another aspect of the embodiments of the present invention, the present invention proposes a freight compartment management server 2 (hereinafter referred to as "management server 2") for mixing chemicals, and the management server 2 includes:

[0112] A monitoring module 201, configured to monitor trigger events;

[0113] The obtaining module 202 is used to obtain the unique ID of the chemical in the compartment when the trigger event occurs;

[0114] Inquiry module 203, configured to inquire about corresponding chemicals according to the identification ID;

[0115] Judging module 204, configured to judge whether the corresponding chemical conflicts with the chemical to be loaded according to the chemical conflict list, and the chemical to be loaded is the chemical to be loaded into the compartment;

[0116] The judging module 204 is also used to judge whether the chemicals in other compartments conflict with the chemicals...

Embodiment 3

[0134] Such as Figure 5 As shown, according to yet another aspect of the embodiment of the present invention, the present invention proposes a cargo compartment management server for mixing chemicals.

[0135] The management server 3 may have relatively large differences due to different configurations or performances, and may include one or more central processing units (central processing units, CPU) 322 (for example, one or more processors) and memory 332, one or more One or more storage media 330 (eg, one or more mass storage devices) storing application programs 342 or data 344 . Wherein, the memory 332 and the storage medium 330 may be temporary storage or persistent storage. The program stored in the storage medium 330 may include one or more modules (not shown in the figure), and each module may include a series of instruction operations on the server. Furthermore, the central processing unit 322 may be configured to communicate with the storage medium 330 , and exe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com