A Decision-Making Method for System Selective Maintenance Oriented to Multiple Task Phases

A decision-making method and multi-task technology, which is applied in the field of system selective maintenance decision-making oriented to multi-task stages, and can solve problems such as unreasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

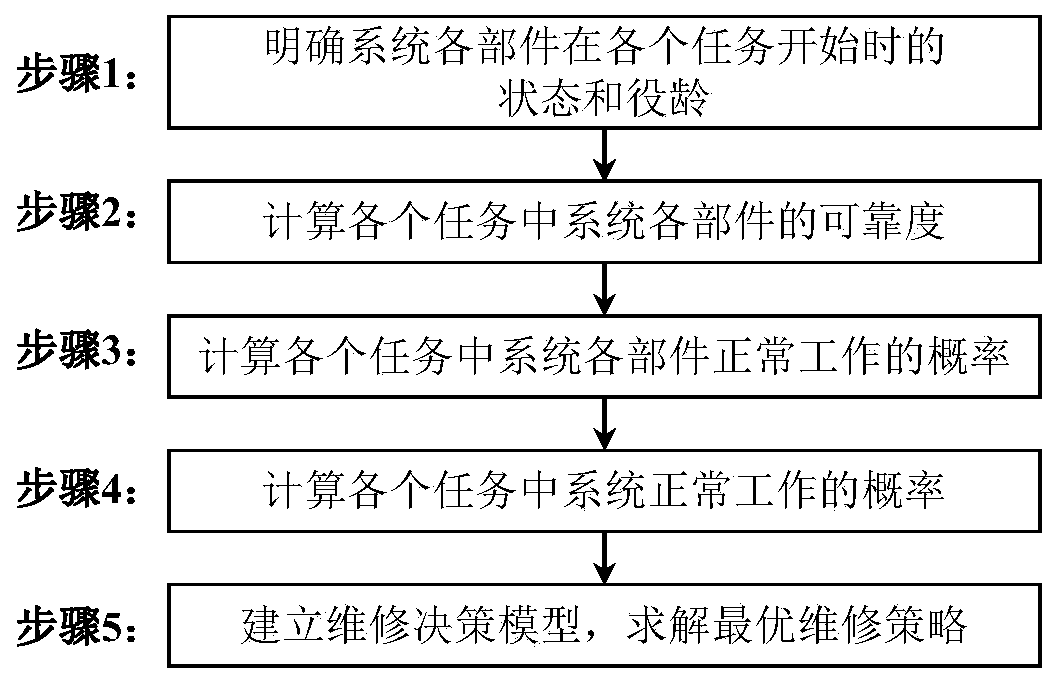

Method used

Image

Examples

Embodiment Construction

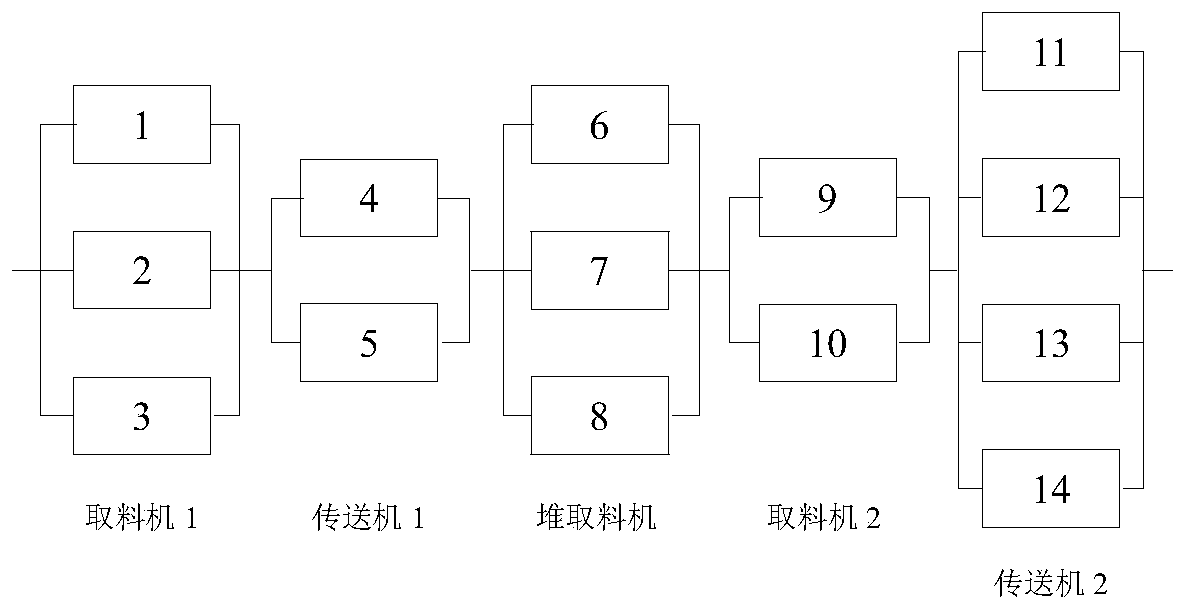

[0076] Attached below Figure 1-2 The present invention will be further elaborated with specific implementation, and a coal transmission system is taken as an example here.

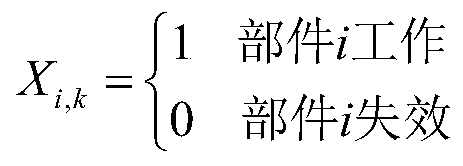

[0077] The coal delivery system is used to power a combustion chamber. There are 5 subsystems in the system, and a total of 14 components are connected in series and parallel. Parts 1-3 make up the feeder 1 to send coal to the conveyor 1, parts 4-5 make up the conveyor 1 to send the coal to the stacker-reclaimer, and parts 6-8 make up the stacker-reclaimer to send the coal to Combustion furnace, parts 9-10 form the feeder 2 and are used to send coal to the conveyor 2, and parts 11-14 form the conveyor 2 to send the coal to the combustion chamber. All components are regarded as a unit, and the failure time obeys the Weibull distribution. The parameters of the Weibull distribution of each component and the maintenance cost ($1000) are shown in Table 1.

[0078] Table 1

[0079]

[0080] Each compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com