Method and system for optimized configuration of energy in hydrogen production station

A technology of energy optimization and configuration method, applied in the field of hydrogen production, can solve the problems of heating and cooling energy consumption of hydrogen production stations, only considering hydrogen production and electricity demand, and not comprehensively considering the heat energy and cooling energy requirements of hydrogen production stations, etc. Achieving the effect of optimizing the configuration comprehensively and optimizing the configuration reasonably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0038] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

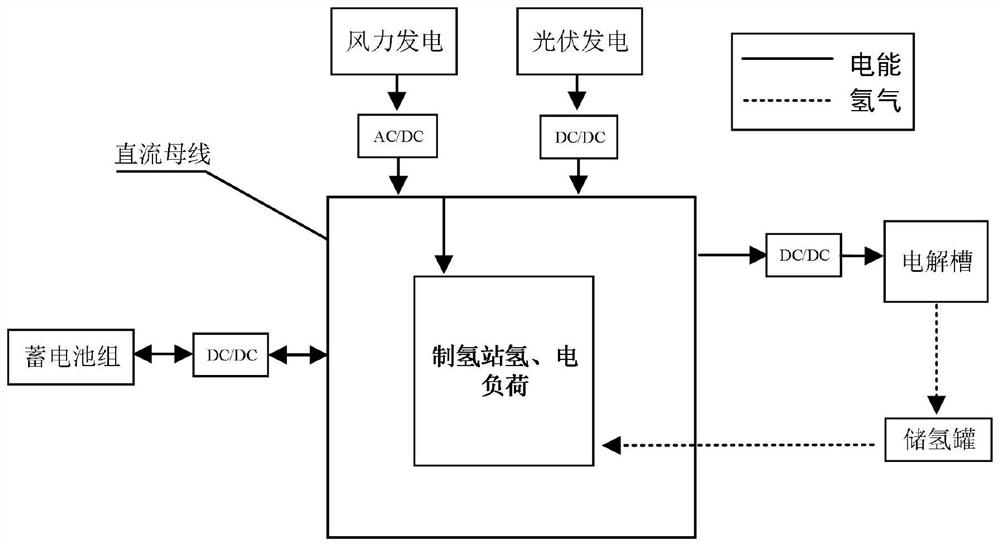

[0039] Such as figure 1 As shown, in the configuration method of the traditional off-grid new energy hydrogen production station, the main equipment includes: wind turbines, photovoltaic power generation battery packs, batteries, electrolyzers and hydrogen storage tanks. Wind generators and photovoltaic power generation battery packs are connected to the DC bus through converters to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com