Manufacturing method of long-life lean liquid lead-acid battery

A technology for lead-acid batteries and manufacturing methods, which is applied in the direction of lead-acid batteries, lead-acid battery electrodes, lead-acid battery construction, etc., can solve problems such as irregularities, unreasonable settings, and short test cycle life, and achieve an increase in the number of cycles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

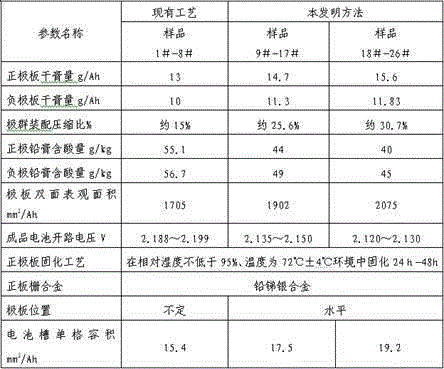

[0007] The GFM-500 sample battery was produced respectively by using the existing technology and the method of the present invention, and the relevant parameters are compared in Table 1.

[0008] Table 1:

[0009]

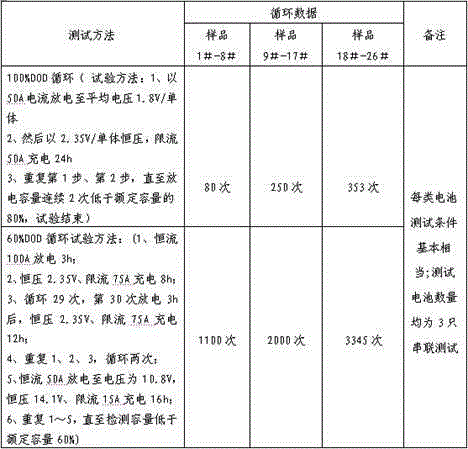

[0010] The battery produced by the method of the present invention is compared with the existing battery cycle life test as shown in Table 2.

[0011] Table 2:

[0012]

[0013] It can be seen through test comparison that the battery (sample 9) made by the present invention # ~17 # and 18 # ~26 # ) 100% DOD cycle times more than 200 times, 60% DOD cycle times more than 1500 times, meet the requirements of relevant standards, compared with the existing battery (sample 1 # ~8 # ) The cycle life is significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com