Method for preparing lithium manganate cathode material by microwave sintering

A cathode material and microwave heat treatment technology, applied in the direction of manganate/permanganate, etc., can solve the problems of high cost and poor performance, and achieve low production cost, reduced synthesis time, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

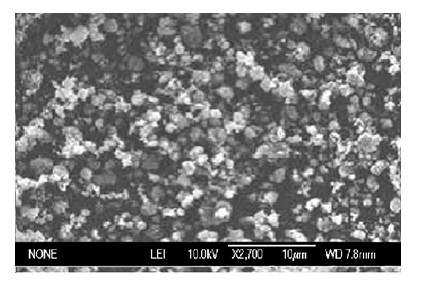

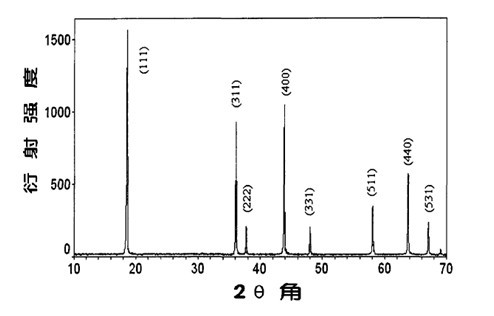

Image

Examples

Embodiment 1

[0044] Embodiment one: LiMn cathode material for lithium-ion batteries 2 o 4 preparation method

[0045] (1) 3600 g of LiOH·H 2 O, 13912 g MnO 2 Put it into the mixer and mix evenly;

[0046] (2) Add 3000 ml of pure water, stir and mix thoroughly to obtain a paste precursor;

[0047] (where LiOH·H 2 O molecular weight 42, MnO 2 The molecular weight is 87, that is, the molar ratio of Li:Mn is 1:1.87)

[0048] (3) Put the paste precursor into a silicon carbide crucible, put the silicon carbide crucible into an industrial microwave oven with a power of 15KW, raise the temperature to 650°C at a rate of 4°C per minute, and keep it for 30 minutes to obtain the positive electrode material LiMn 2 o 4 .

[0049] This example can prepare about 14.5kg LiMn 2 o 4 , the amount of pure water added is equivalent to LiMn 2 o 4 21% of the volume.

Embodiment 2

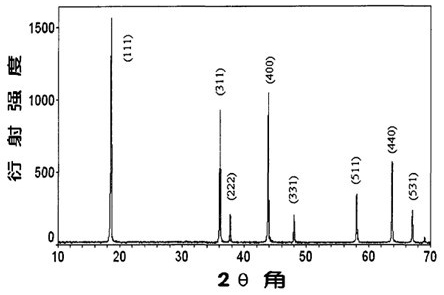

[0050] Embodiment two: LiMn cathode material for lithium-ion batteries 2 o 4 preparation method

[0051] (1) 3000 grams of lithium carbonate, 13912 grams of MnO 2 Put it into the mixer and mix well;

[0052] (Li 2 CO 3 Molecular weight 73.80, MnO 2 The molecular weight is 87, in this case the molar ratio of Li:Mn is 1:1.97)

[0053] (2) Add 4000 ml of pure water, stir and mix well to obtain a paste precursor;

[0054] (3) Put the paste precursor into a kraft paper crucible, put the kraft paper crucible into an industrial microwave oven, the power of the industrial microwave oven is 20KW, heat up to 700°C at a rate of 6°C per minute, and keep it for 40min to obtain LiMn 2 o 4 .

[0055] This example can prepare about 14.5kg LiMn 2 o 4 , where the amount of pure water added is equivalent to LiMn 2 o 4 28% of the volume.

Embodiment 3

[0056] Embodiment three: It is basically the same as Embodiment 1, the difference is that:

[0057] A graphite crucible was used instead of a silicon carbide crucible, and the microwave heat treatment temperature was 680°C, and the temperature was kept for 50 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com