High-performance starch/oxygen fuel cell based on microbial surface co-display sequential enzyme

A surface co-display, fuel cell technology, used in biochemical fuel cells, battery electrodes, circuits, etc., can solve problems such as limiting energy conversion efficiency, improve utilization, improve output power density and stability, and achieve efficient utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Preparation of bioanode

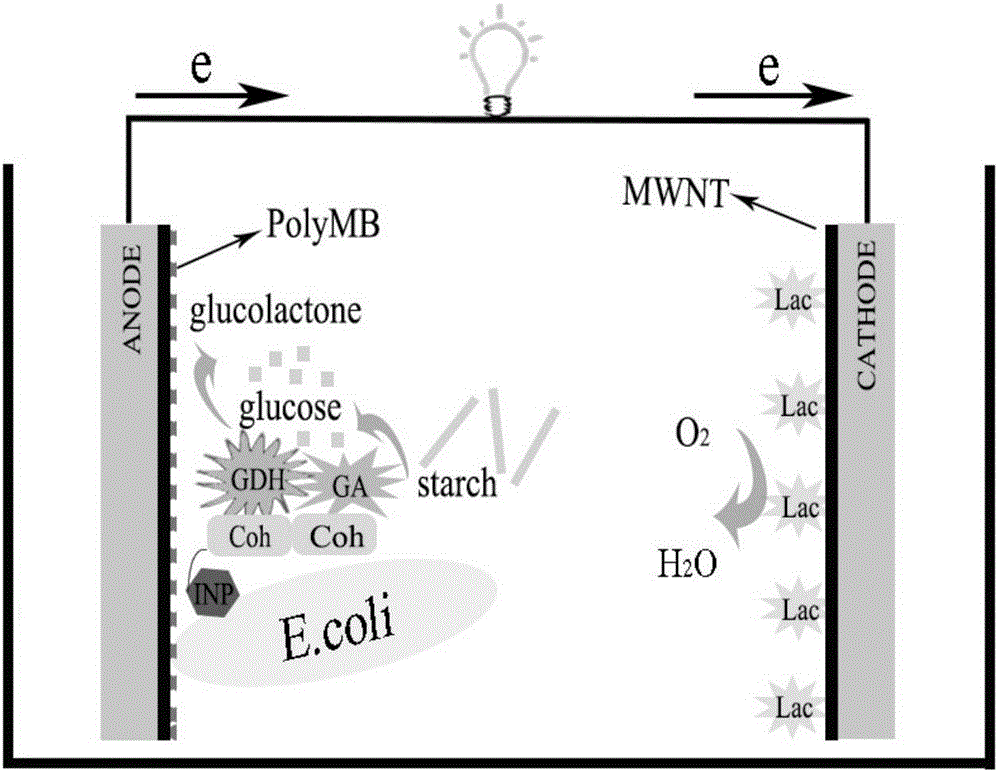

[0027] Bioanode Catalyst (GA&GDH-E.coli) is a sequential enzyme surface co-display system obtained by co-displaying the gene sequence (gdh-m) of glucoamylase (GA) and glucose dehydrogenase mutant on the surface of Escherichia coli (E.coli) ; Among them, the proportion of GA and GDH display numbers is 3:1.

[0028] The preparation of the above-mentioned sequential enzyme surface co-display system was obtained by referring to the method described in the publication No. 105624077A, entitled A sequential enzyme surface co-display system and its application.

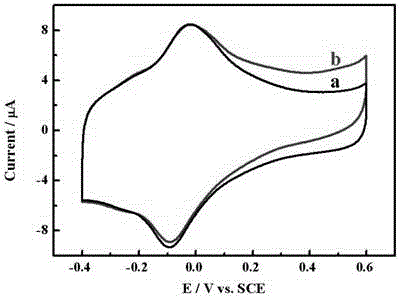

[0029] First, 2 mg of MWNTs was added to 1 mL of DMF and sonicated until uniformly dispersed. The bare glassy carbon electrode (inner diameter 3mm) was polished to a mirror surface with 0.3 μm and 0.05 μm alumina powder in turn, rinsed with deionized water after polishing, and then ultrasonicated in anhydrous ethanol and ultrapure aqueous solution mixed at a volume ratio of 1:1 Wash, rins...

Embodiment 2

[0038] Construction and Testing of Starch / Oxygen Fuel Cells

[0039] The assembly of the starch / oxygen fuel cell was to simultaneously immerse the modified bioanode and biocathode in a solution containing 4mM NAD + , 0.5mM ABTS and 0.2M citric acid-Na 2 HPO 4 (pH=4.8) buffer solution. The measurement of its energy density and stability is done in the above solution saturated with oxygen.

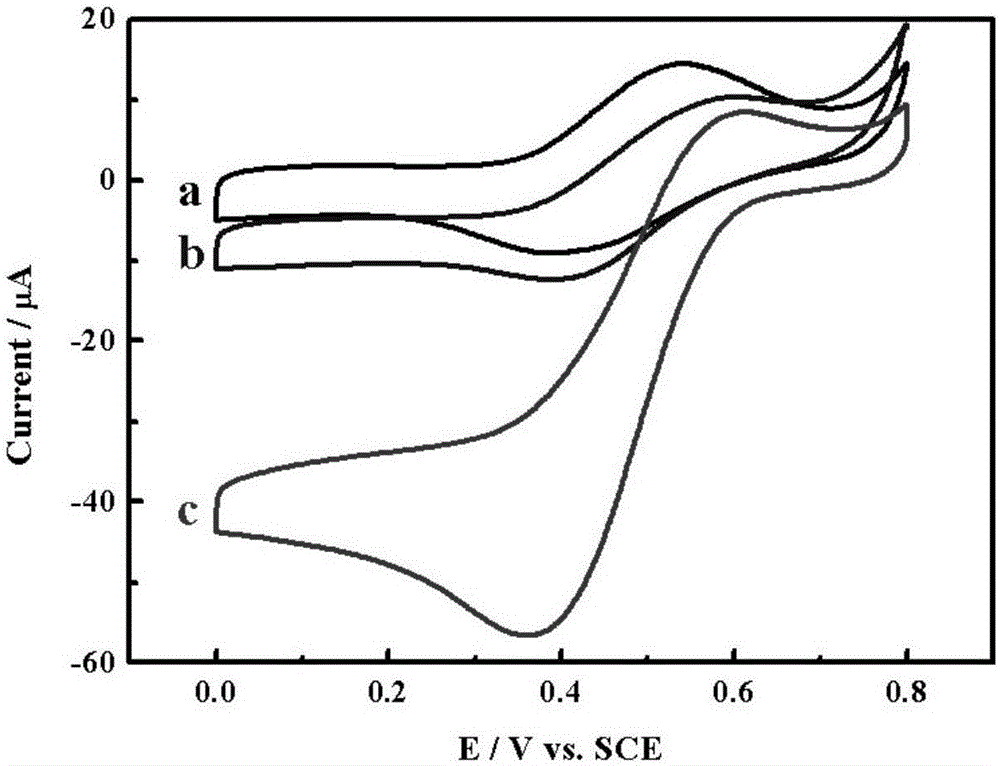

[0040] In the detection process, the starch / oxygen fuel cell constructed above was based on GA&GDH-E.coli immobilized on polymethylene blue modified MWNTs as bioanode, and laccase immobilized on MWNTs as biocathode. Starch fuel is catalyzed by GA&GDH-E.coli on the bioanode, decomposed step by step, oxidized to gluconolactone, and releases electrons, while oxygen is reduced by laccase on the biocathode to generate positive charges. The battery supplies power to the external circuit to realize the energy conversion of starch fuel. The open circuit potential of this starch / oxygen fuel cell c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com