Battery pack air cooling system

An air-cooling system and battery pack technology, applied to secondary batteries, battery/fuel cell control devices, circuits, etc., can solve problems such as access, achieve heat dissipation balance, ensure charging and discharging, and good heat dissipation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

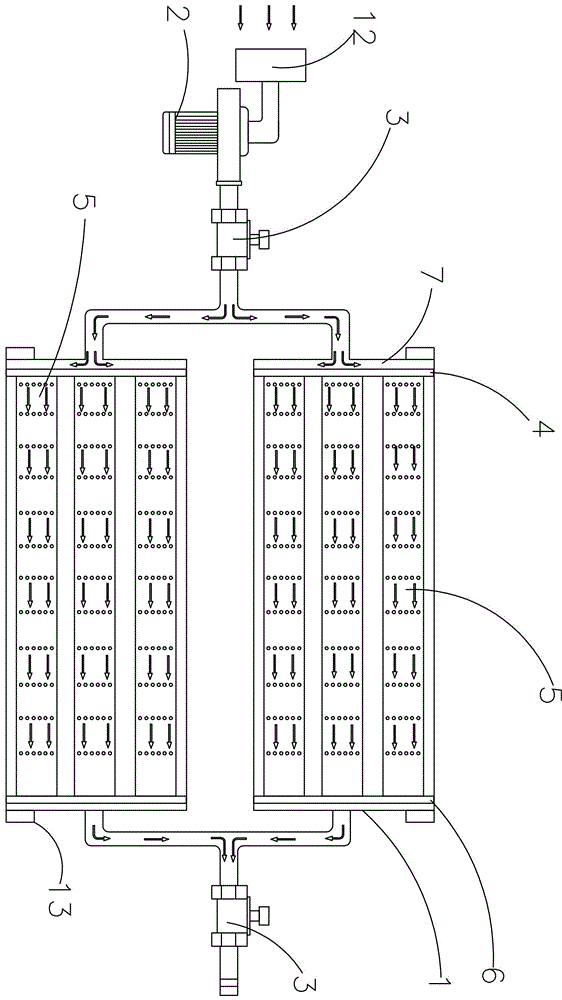

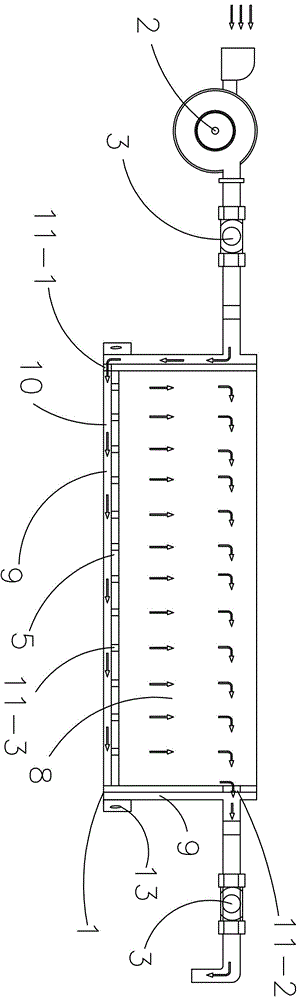

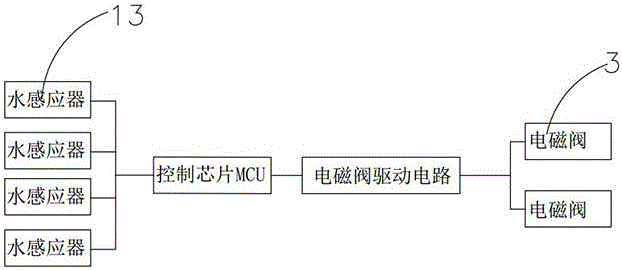

[0036] as attached figure 1 And attached figure 2 As shown, a battery pack air-cooling system includes a box body 1, a fan 2 located outside the box body 1 and connected to the inside of the box body through a draft tube, and a wind cover connected to the air inlet of the fan 2 through a downflow tube 12 and the waterproof device that is arranged on the casing 1 outside.

[0037] The first deflector 4 and the second deflector 6 are connected between the front and rear sides of the inner cavity of the box body 1, and the top of the first deflector 4 and the top of the second deflector 6 are connected to the top wall of the inner cavity of the box. , the bottom end of the first deflector 4 and the bottom end of the second deflector 6 are connected to the bottom wall of the box cavity, between the first deflector 4 and the second deflector 6 and close to the bottom of the box cavity Three third deflectors 5 are connected; the three third deflectors 5 are arranged in parallel b...

Embodiment 2

[0045] as attached figure 1 And attached figure 2 As shown, a battery pack air-cooling system includes a box body 1, a fan 2 located outside the box body 1 and connected to the inside of the box body through a draft tube, and a wind cover connected to the air inlet of the fan 2 through a downflow tube 12 and the waterproof device that is arranged on the casing 1 outside.

[0046] The first deflector 4 and the second deflector 6 are connected between the front and rear sides of the inner cavity of the box body 1, and the top of the first deflector 4 and the top of the second deflector 6 are connected to the top wall of the inner cavity of the box. , the bottom end of the first deflector 4 and the bottom end of the second deflector 6 are connected to the bottom wall of the box cavity, between the first deflector 4 and the second deflector 6 and close to the bottom of the box cavity Three third deflectors 5 are connected; the three third deflectors 5 are arranged in parallel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com