Multi-rotor motor

A multi-rotor and rotor technology, applied in the field of aircraft, can solve problems such as motor overheating, motor failure, and propulsion system failure, and achieve the effects of reducing the probability of failure, improving heat dissipation, and avoiding the wrong installation of positive and negative propellers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

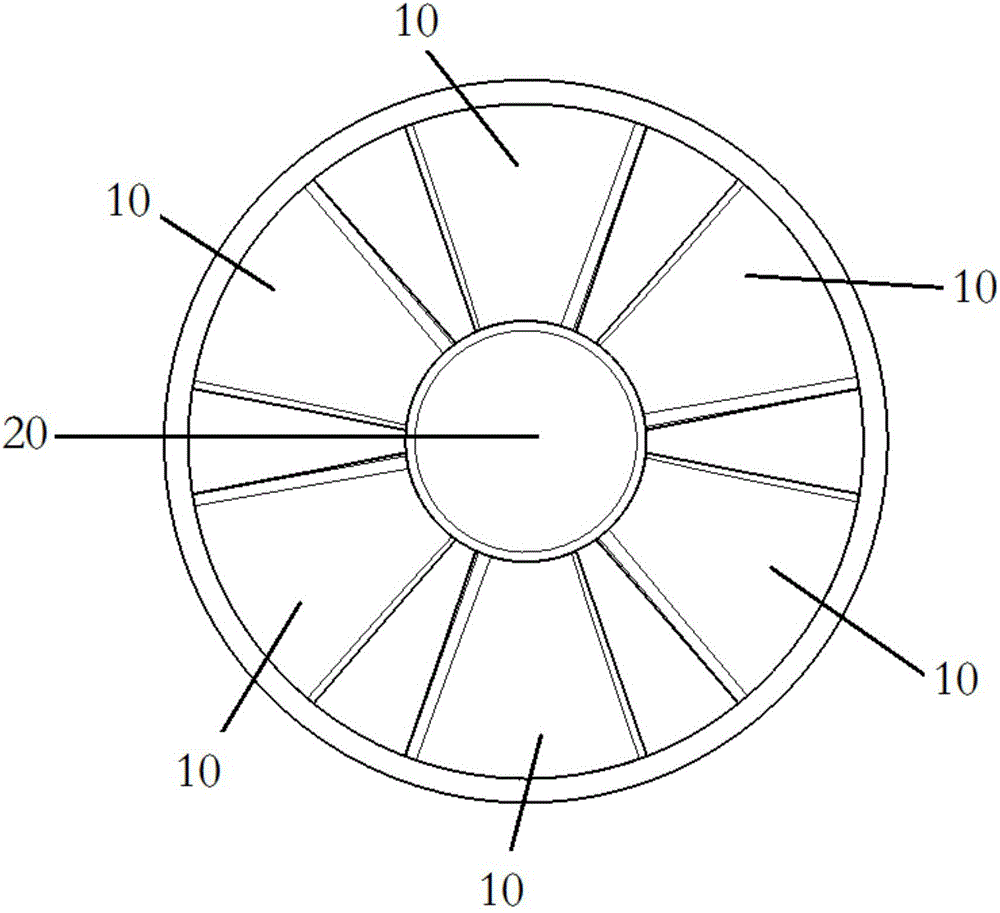

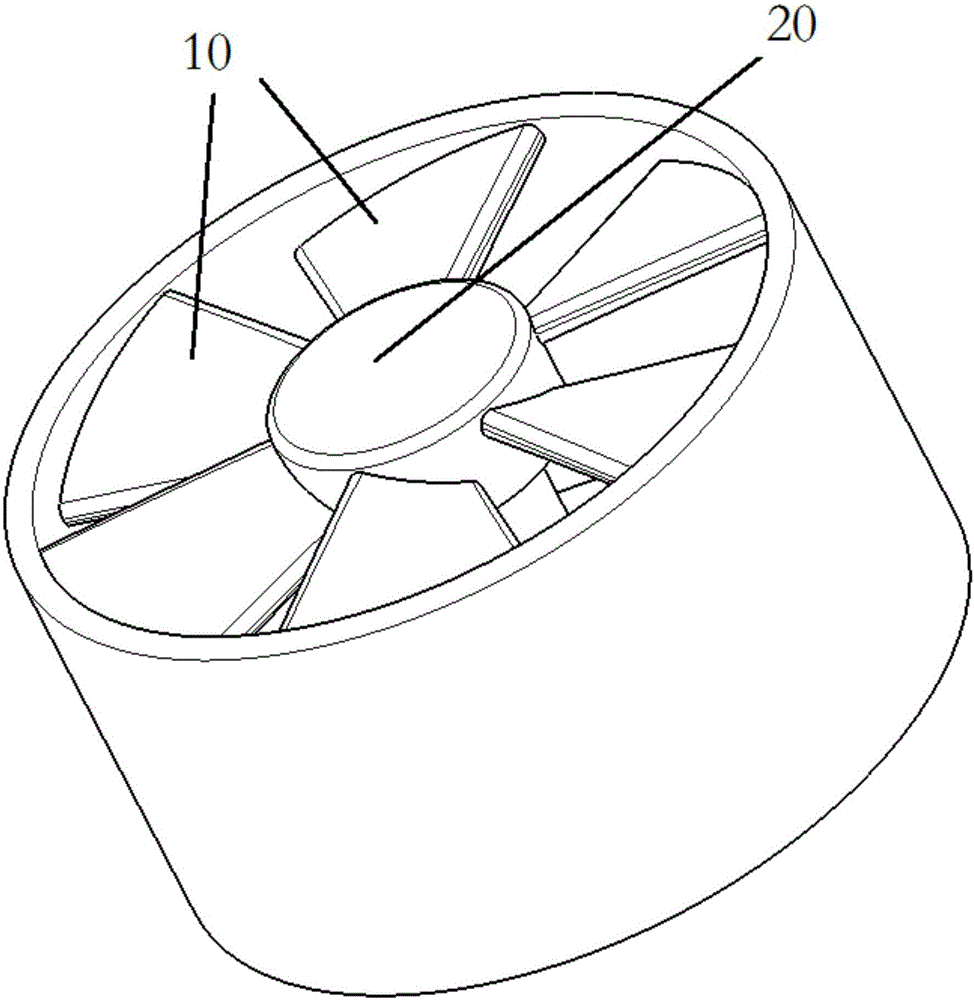

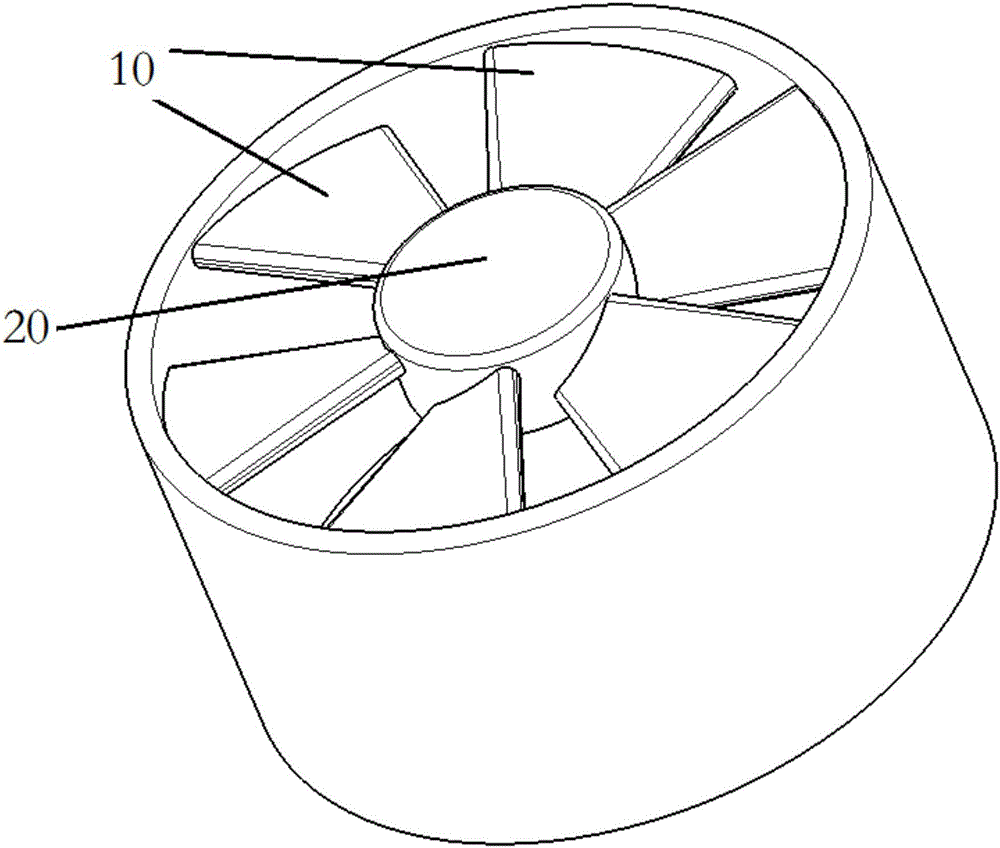

[0021] figure 1 is a schematic top view of a multi-rotor motor according to a preferred embodiment of the present invention. figure 2 It is an axial perspective schematic diagram of a multi-rotor motor rotating in the forward direction according to a preferred embodiment of the present invention. image 3 It is an axial perspective schematic diagram of a counter-rotating multi-rotor motor according to a preferred embodiment of the present invention. Figure 4 is a motor sectional view of a multi-rotor motor according to a preferred embodiment of the present invention.

[0022] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the multi-rotor motor according to the preferred embodiment of the present invention includes: a plurality of fan-shaped blades 10 formed on the top of the external rotor of the motor, wherein the root of each fan-shaped blade 10 is fixedly connected to the rotor shaft 20 of the multi-rotor motor, each The tip of the fan-shaped blade 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com