Automatic heating device of generator thrust block

A thrust head and generator technology, applied in the direction of induction heating device, coil device, induction heating, etc., can solve the problems of generator thrust head volume, low installation accuracy, uneven heating, etc., and achieve good thermal sleeve connection, The process is stable and reliable, and the heating effect is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

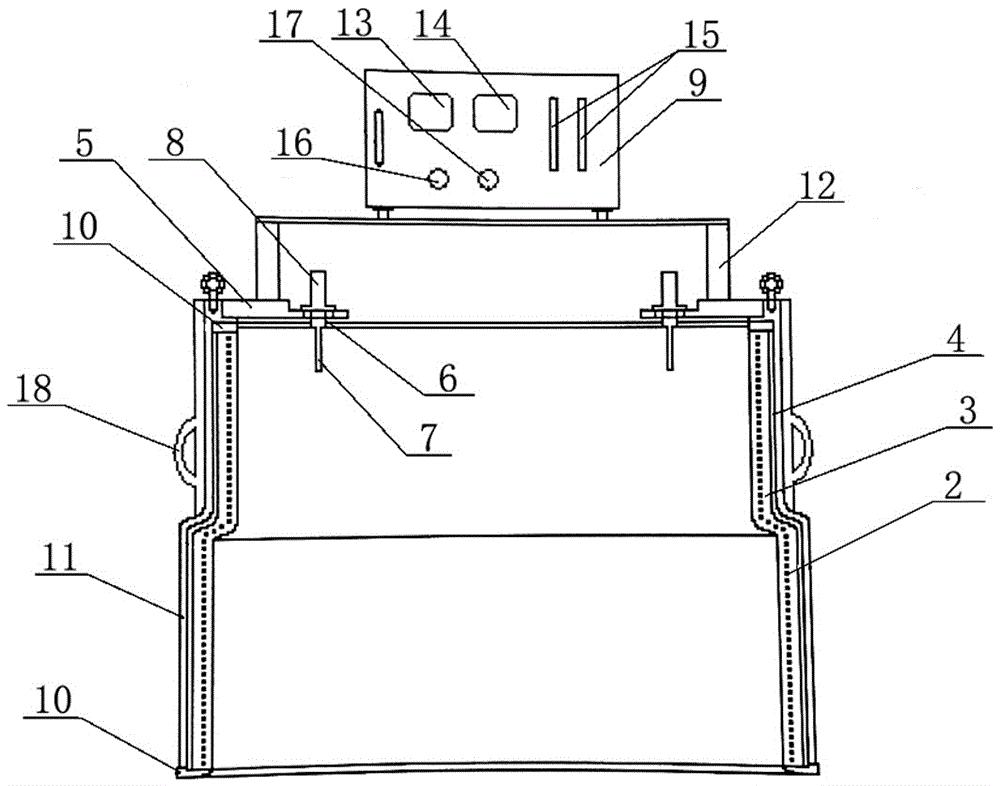

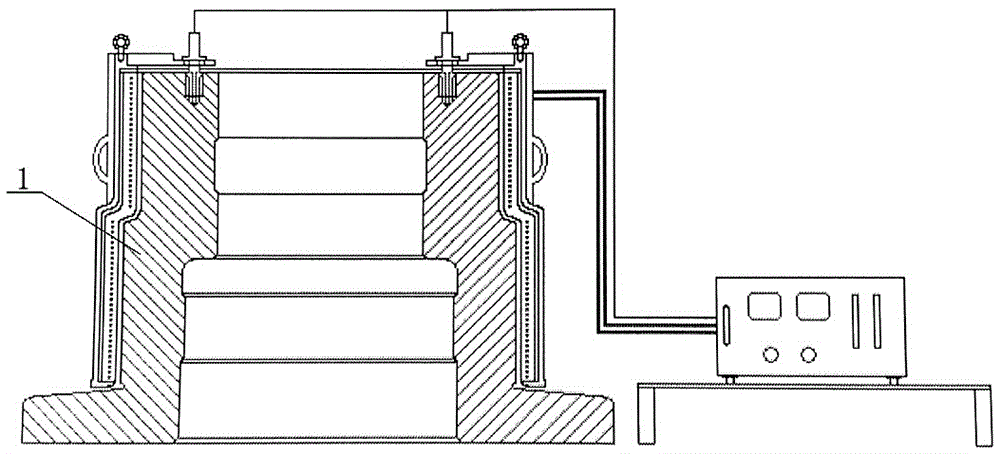

[0016] Embodiment: Fix the heating coil 2 in an epoxy material with good heat dissipation performance, shape and solidify it into a cylindrical shape according to the shape of the outer wall of the thrust head 1, and use a non-magnetic metal outer frame 4 (such as the upper and lower stainless steel ring brackets, stainless steel reinforcements) ribs, etc.) for anti-deformation fixation to realize the integration of the heating device.

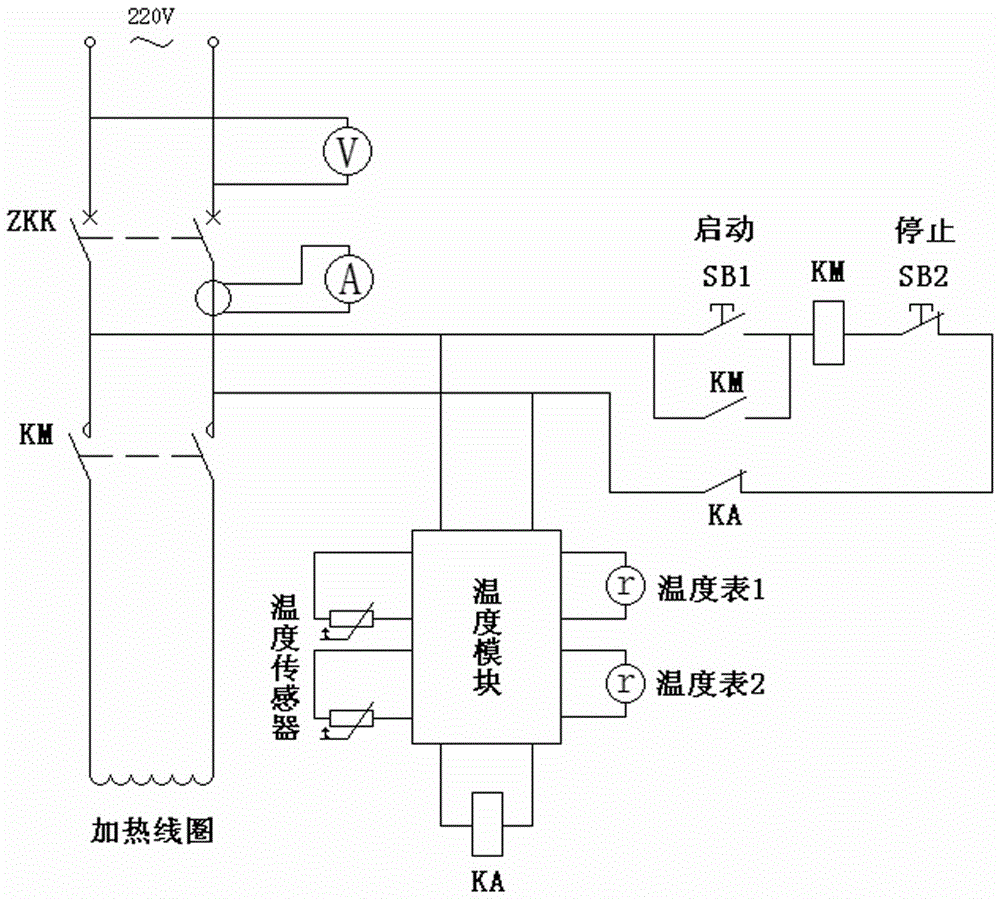

[0017] The temperature sensor with electric control contact is used to replace the thermometer with a more sensitive reaction effect; the temperature measurement of the thrust head is changed from one point temperature measurement to two point temperature measurement and two point temperature control, which improves the accuracy of the thrust head heating situation and strengthens the thrust head heating. Safety monitoring of temperature process.

[0018] The power supply control box 9 is arranged on the top central position of the heating dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com