Industrial factory lamplight terminal control system based on voltage stabilizer

A terminal control system and industrial plant technology, applied in energy-saving control technology, light source, electric light source, etc., can solve the problems of high cost, limited development prospects of lighting terminal control system, complex wiring, etc., and achieve low cost and network layout. Intuitive and scalable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

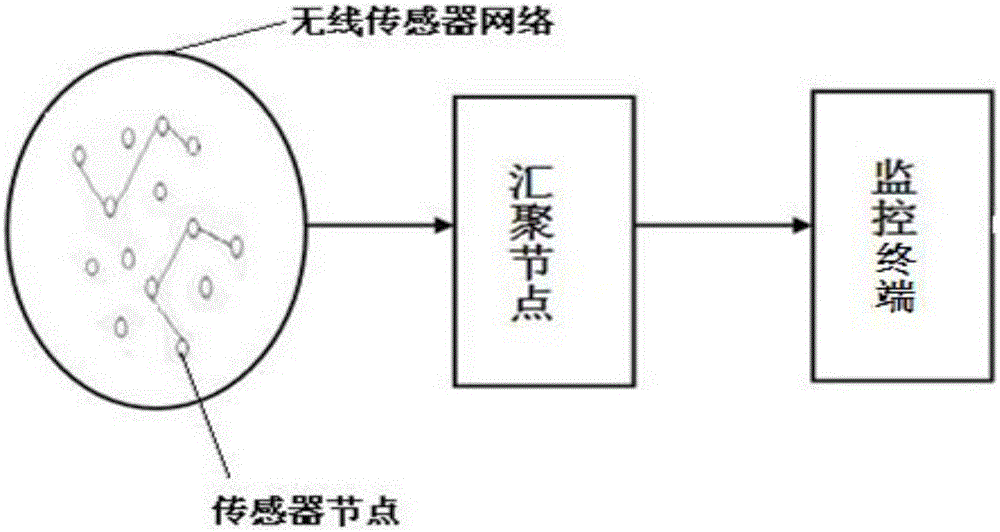

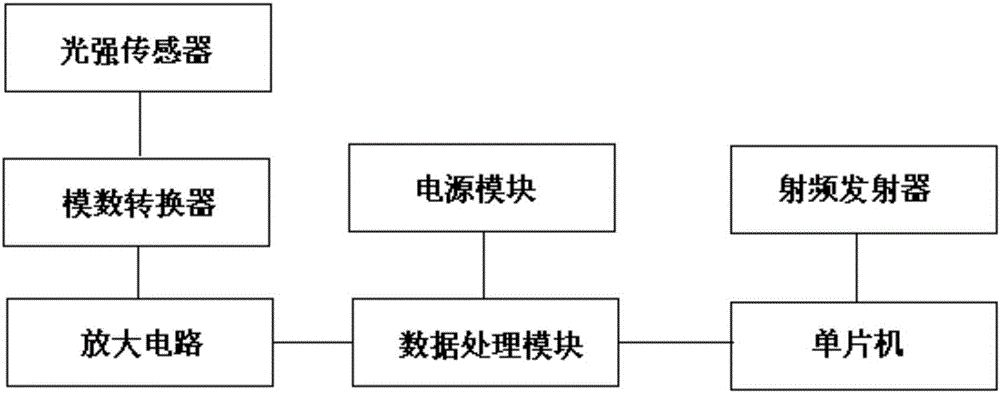

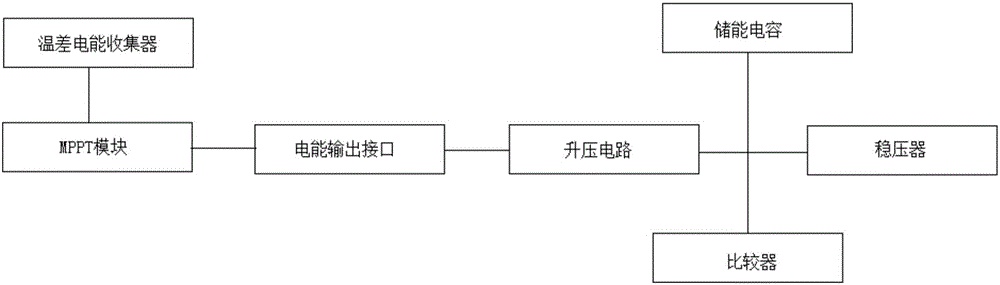

[0022] Such as figure 1 As shown, a voltage stabilizer-based industrial plant light terminal control system includes a monitoring terminal, a convergence node, and a wireless sensor network composed of a plurality of sensor nodes with detected light parameters of the plant; the wireless sensor network connects the sensor nodes The collected lighting data is transmitted to the aggregation node, and the aggregation node uploads the received lighting data to the monitoring terminal; the sensor node of the present invention forms a multi-hop, self-organizing wireless sensor network through wireless communication, and the wireless sensor network composed of multiple light sensors The sensor network intelligently monitors the brightness of the factory building. The self-organizing network has strong capabilities and can monitor the brightness of the fact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com