Fabrication method of multilayer, large-size and high-speed back panel

A high-speed backplane and manufacturing method technology, which is applied in multilayer circuit manufacturing, printed circuit manufacturing, computer design circuit, etc., can solve problems such as uneven back drilling methods, excessive depth, and insufficient pressing temperature of intermediate products. Achieve the effects of reducing production equipment investment, reducing the number of layers and height, and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

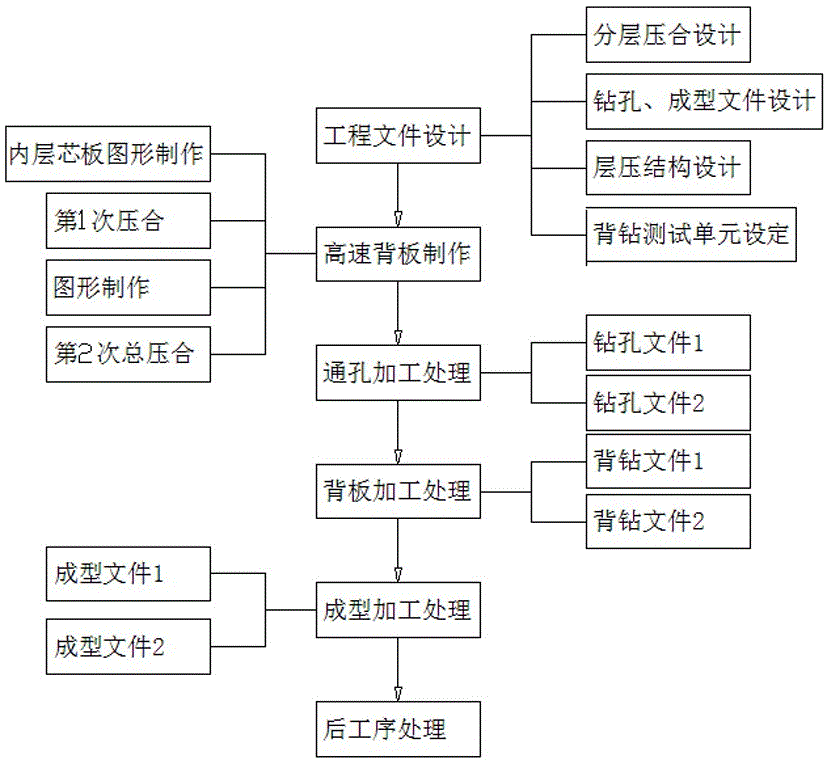

[0061] Such as Figure 1 to Figure 12 As shown, a method for manufacturing a multi-layer large-size high-speed backplane is characterized in that: comprising the following steps:

[0062] The first step is engineering document design, including

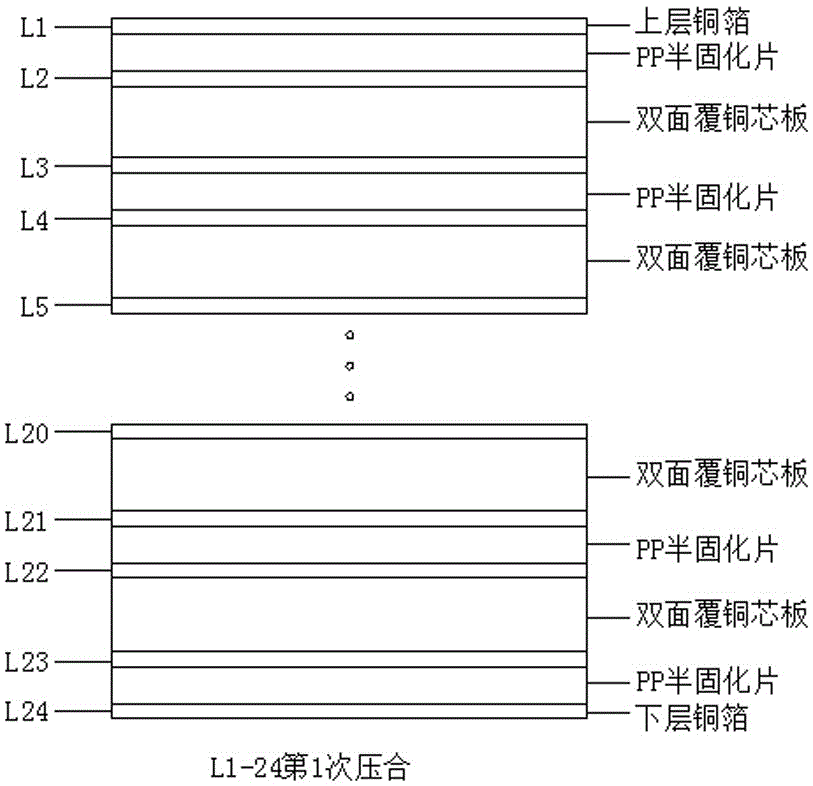

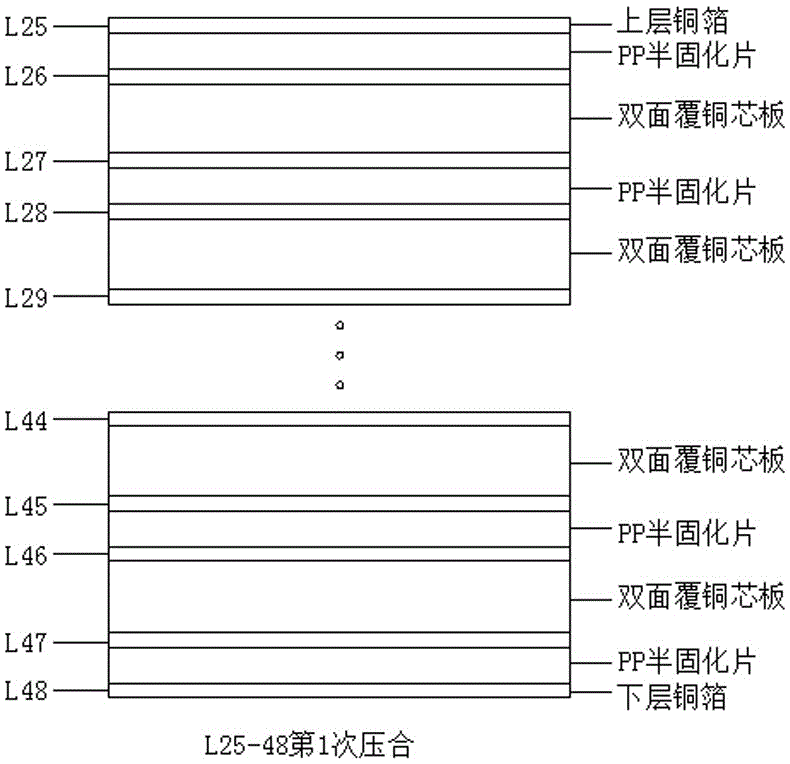

[0063] 1.1) Layered pressing design, the layered pressing is to change the conventional one-time pressing forming method into multiple pressing forming methods according to the number of layers of the product, specifically, the layered pressing is based on the number of product layers According to the number of layers, the products are divided into multiple groups, and the products of each group are pressed separately, and then the products of each group after the first ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com