Filter system and filter element having a glass fiber filter medium and a sintered body

A filtration system and glass fiber technology, applied in the direction of loose filter material filter, filtration separation, membrane filter, etc., can solve the problems of shortening the service life of filter elements, failure of the barrier function of filter media, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

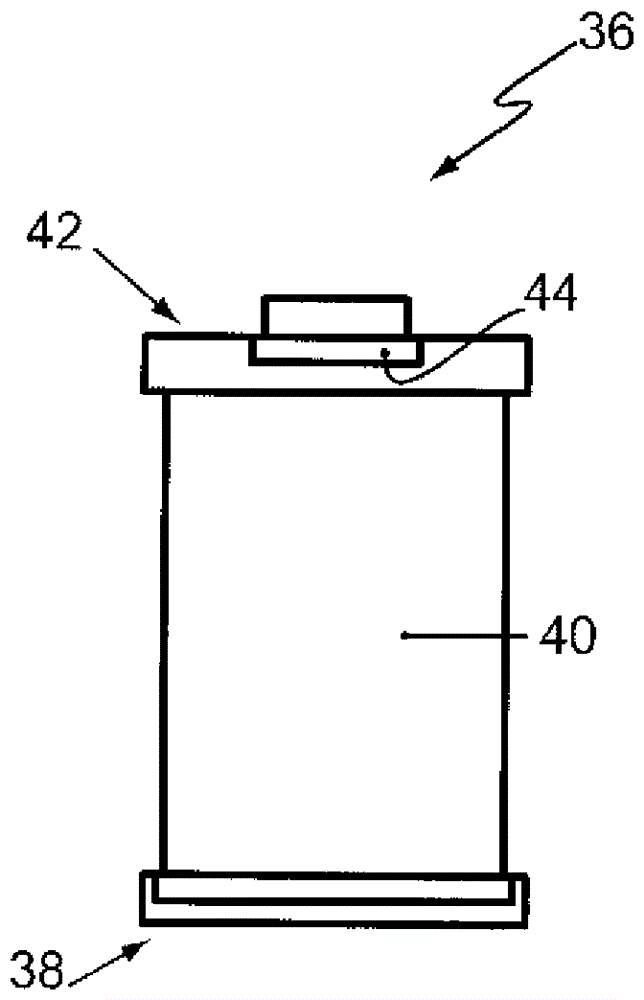

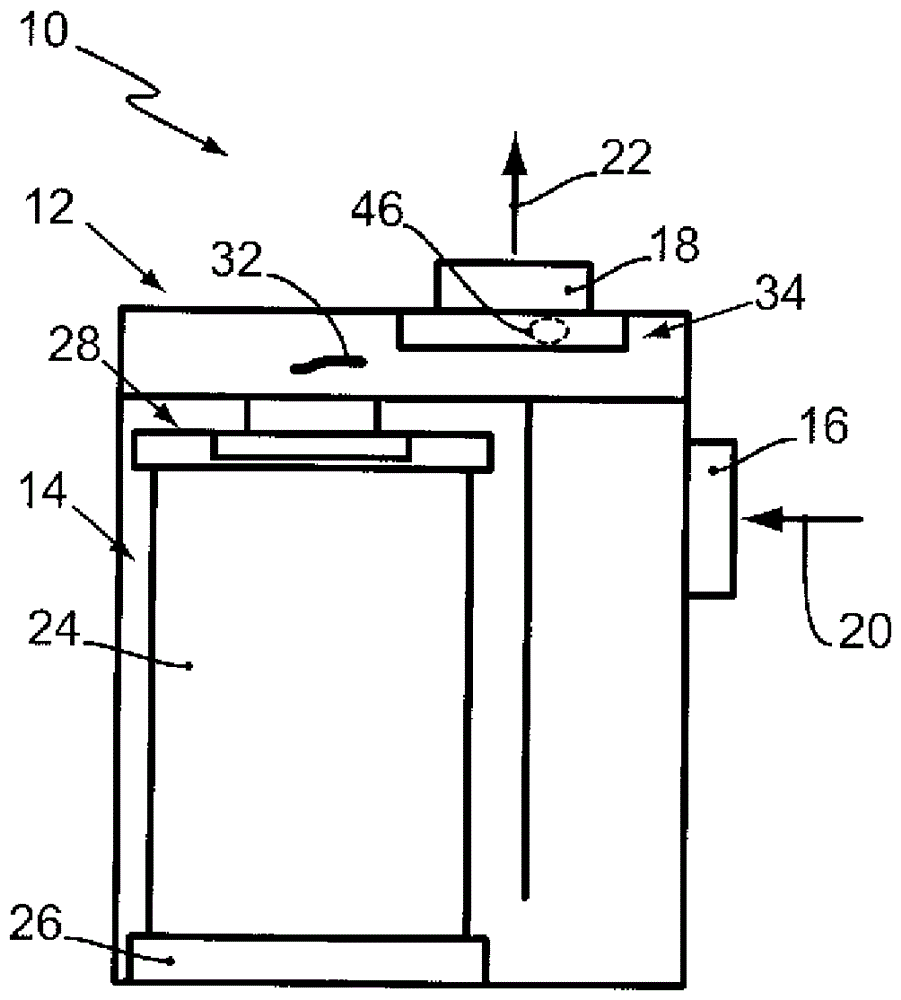

[0031] figure 1 A filter system 10 according to the invention is shown. Filtration system 10 includes a filter housing 12 . A first replaceable filter element 14 is arranged in the filter housing 12 .

[0032] The filter housing 12 includes an inlet 16 and an outlet 18 for the fluid to be filtered, in particular for fuel. The filter housing 12 is therefore flowable as indicated by the arrows 20 , 22 , the filtering process mainly taking place in the first filter element 14 .

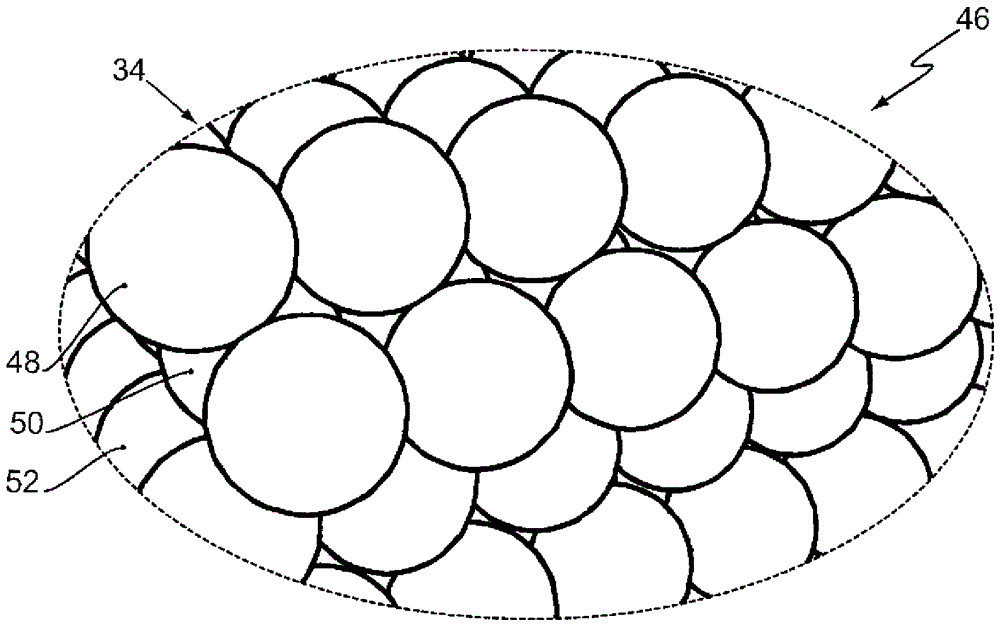

[0033] The first filter element 14 has a filter medium 24 . The filter medium 24 is arranged between a first end plate 26 and a second end plate 28 of the filter element 14 and is designed as a glass fiber filter medium 24 . Individual glass fibers can break out of the glass fiber filter media 24 and foul the fluid. Components 32 of fiberglass filter media 24 are shown in figure 1 shown particularly large. The actual component 32 of the glass fiber filter medium 24 has a length of up to several mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com