Fan shroud

A fan cover and fan technology, which is applied to the cooling of engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of increased man-hours and manufacturing costs, complicated molds, and inability to use injection-molded fan covers to suppress noise deterioration, The effect of suppressing pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. In addition, between the following embodiments including other embodiments described later, the same reference numerals are used in the drawings for the same or equivalent parts.

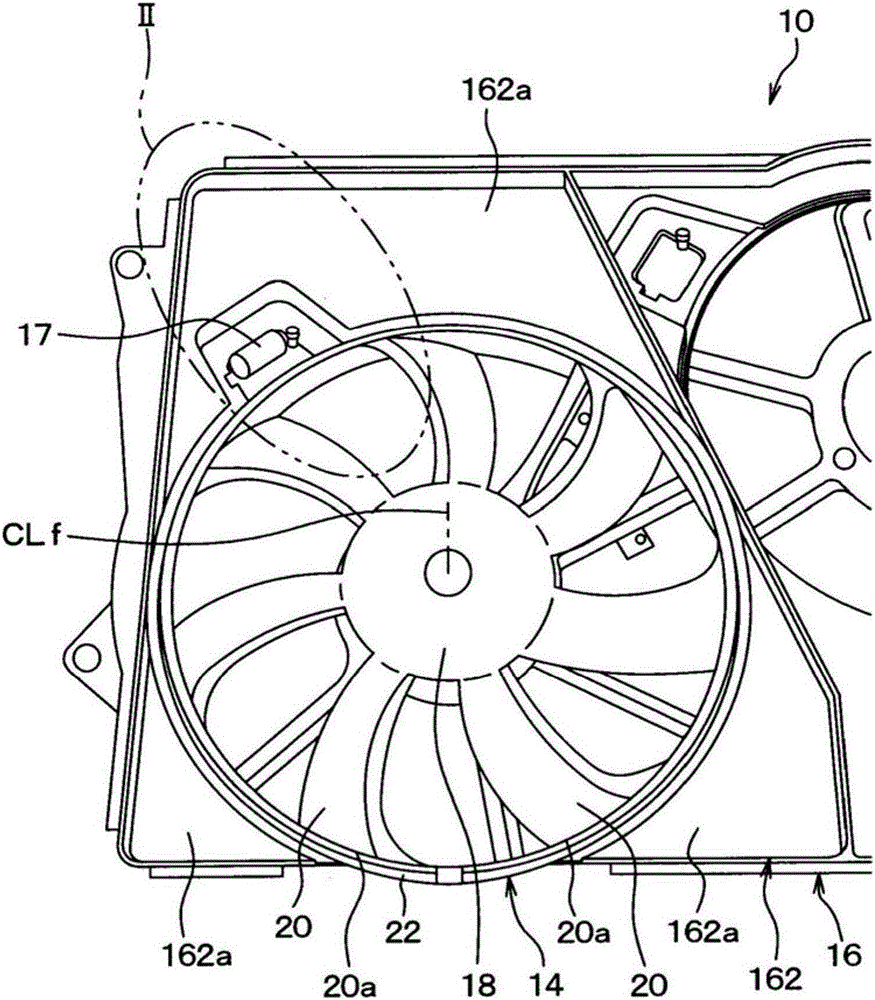

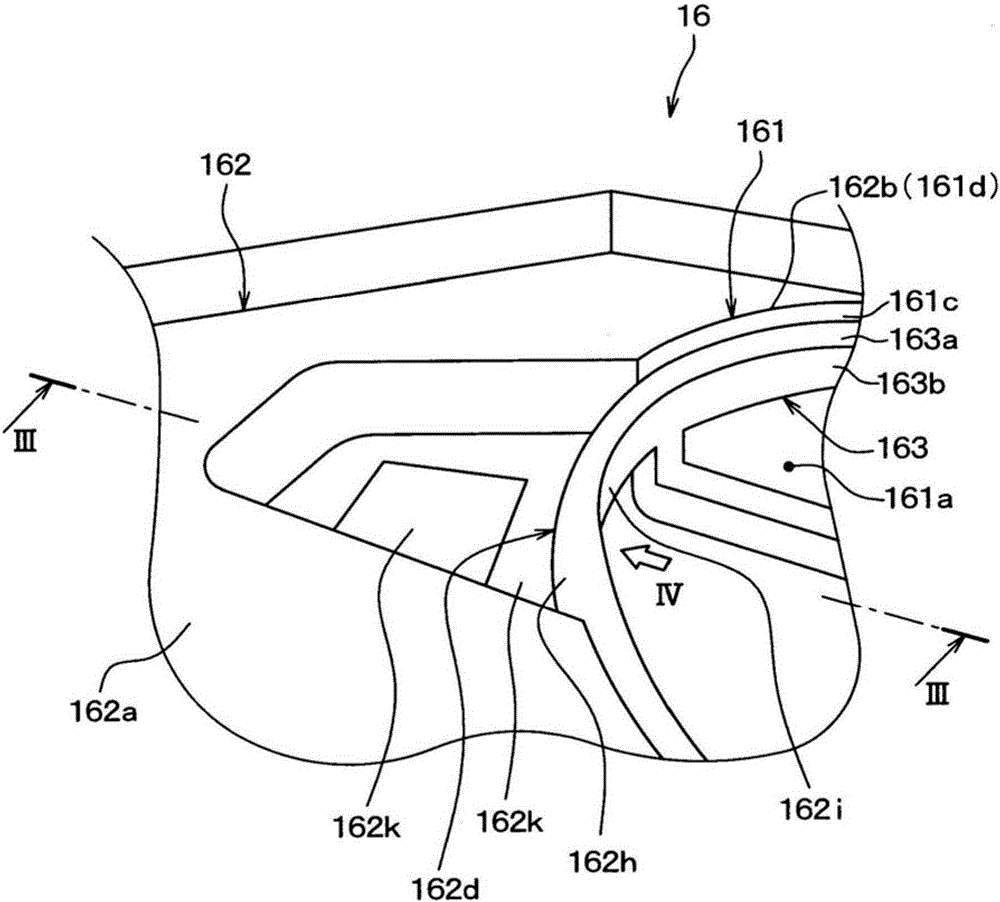

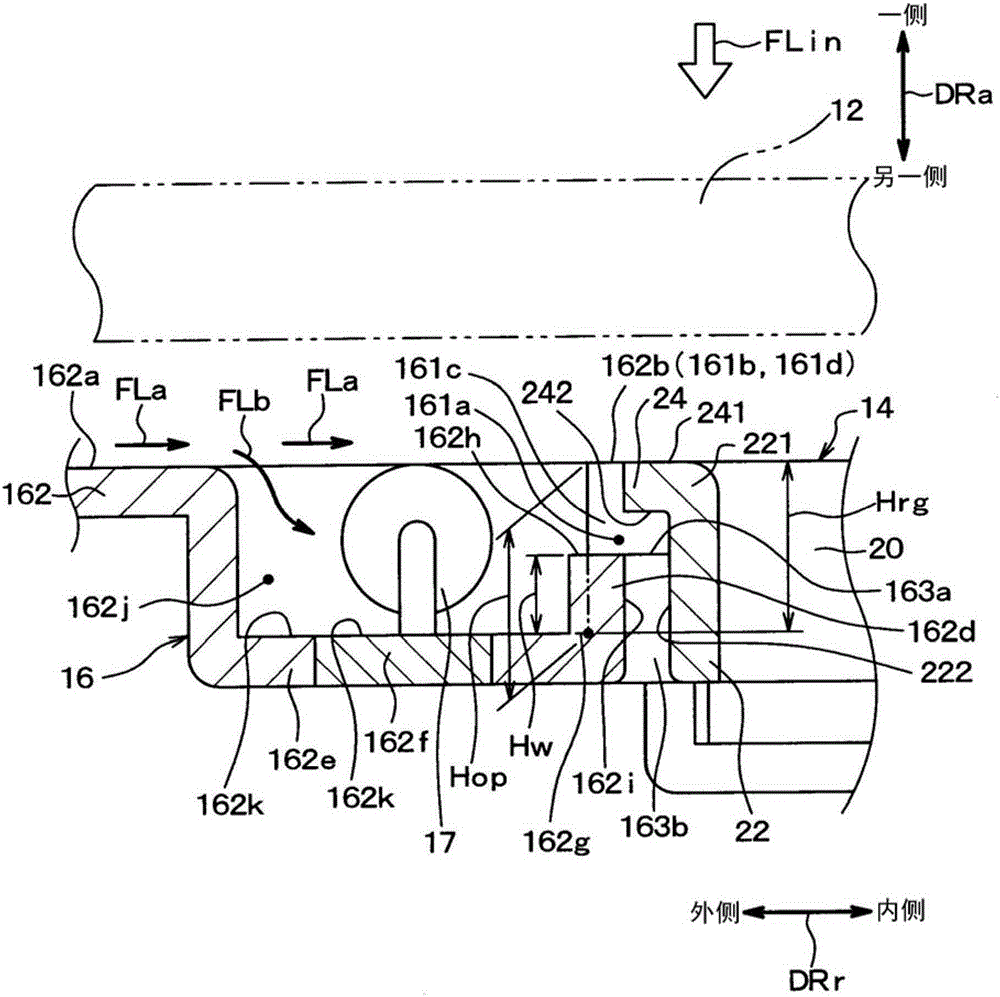

[0026] figure 1 A perspective view of a blower 10 with a fan cover 16 to which the present invention is applicable. figure 1 The blower 10 shown in is an axial flow blower for vehicles, which makes the outside air (air) flow to the radiator 12 (refer to image 3 ). The radiator 12 is a heat exchanger for cooling the cooling water of the vehicle running engine by exchanging heat between outside air and the cooling water of the vehicle running engine.

[0027] Blower 10 is arranged behind the vehicle relative to radiator 12 . Specifically, the air blower 10 is arranged on the downstream side of the radiator 12 in the flow direction of the air passing through the radiator 12 . The air blowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com