Engine rotation speed control device

A technology of engine speed and control device, applied in the direction of engine control, machine/engine, electrical control, etc., can solve problems such as problems with the convergence of engine speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

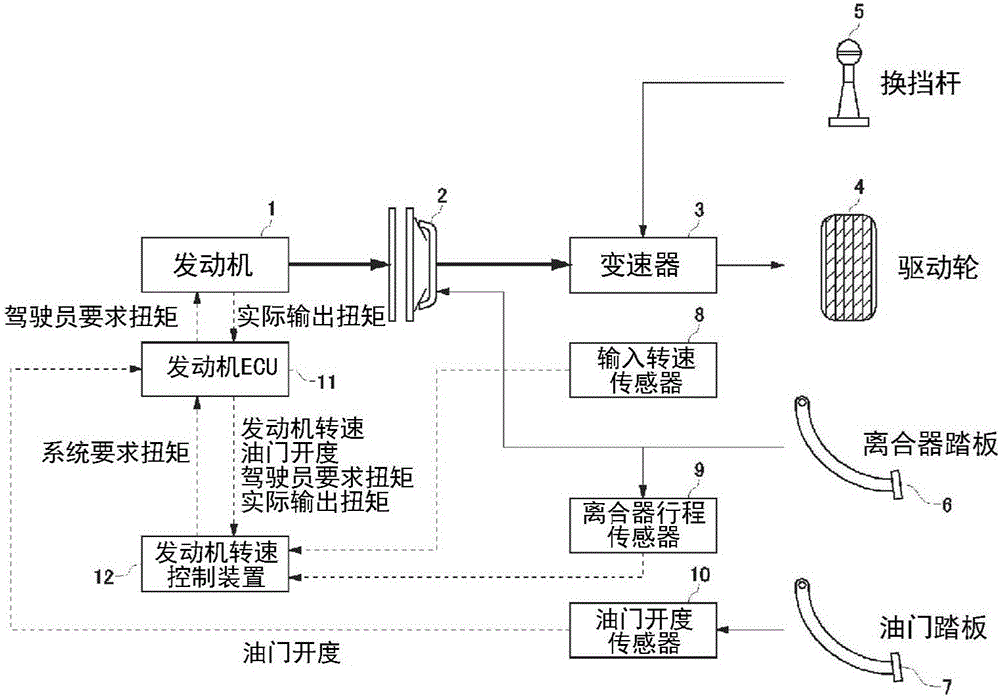

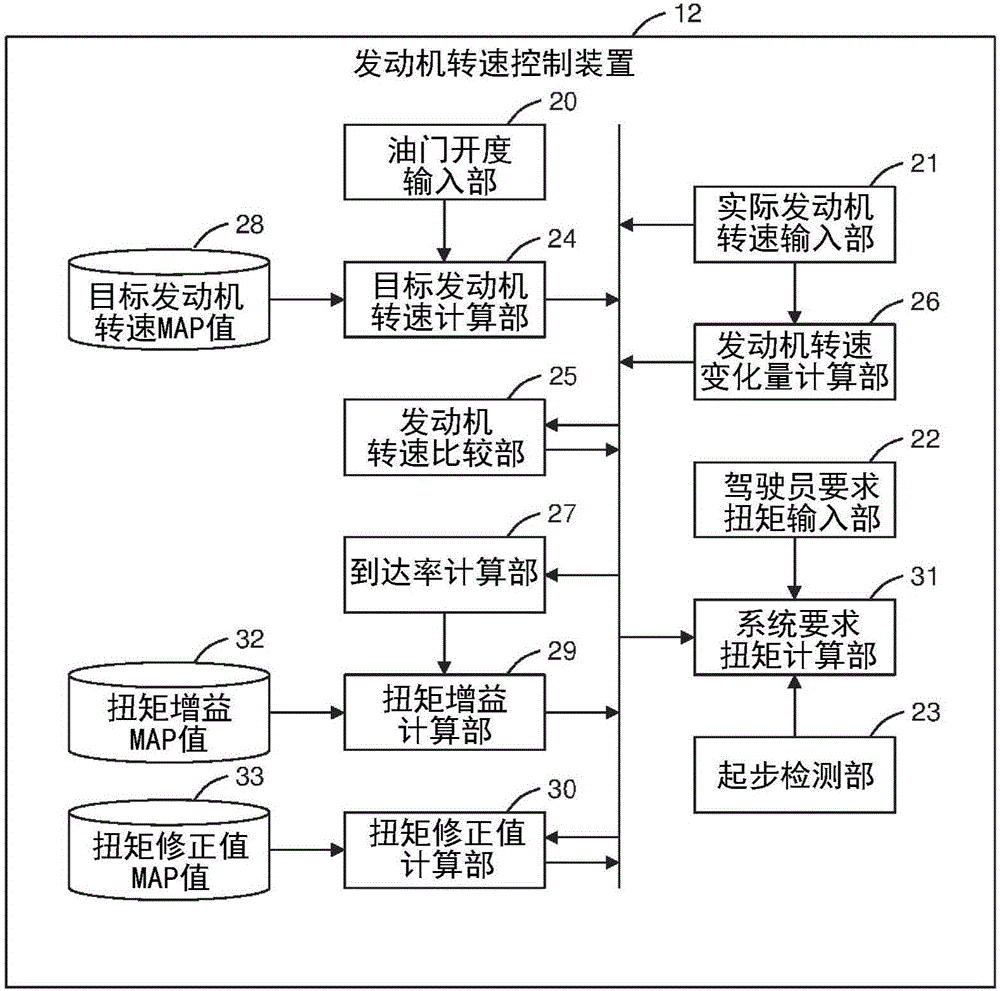

[0040] Hereinafter, an engine rotational speed control device according to an embodiment of the present invention will be described with reference to the drawings. In the present embodiment, the case of an engine rotational speed control device used in a vehicle or the like equipped with a manual transmission is exemplified.

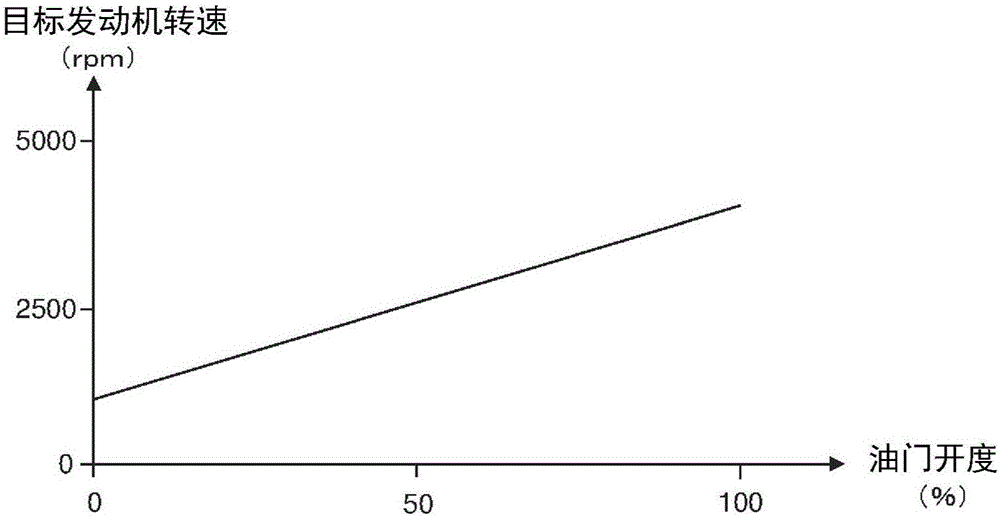

[0041] The configuration of the engine rotational speed control device according to the embodiment of the present invention will be described with reference to the drawings. figure 1 It is a figure explaining the outline of the vehicle equipped with the engine rotational speed control apparatus of this embodiment. like figure 1 As shown, the vehicle has an engine 1 , a clutch 2 and a transmission 3 . The engine 1 is one of known internal combustion engines, and is, for example, a gasoline engine using gasoline as a fuel or a diesel engine using light oil as a fuel. The transmission 3 is, for example, a manual transmission having a plurality of (for ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com