A carburetor with starting oil system

A carburetor and oil system technology, applied in carburetor, charging system, engine components, etc., can solve the problems of high cost and complex structure of carburetor, and achieve low cost, less machining process and tool conversion Action, effect of compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

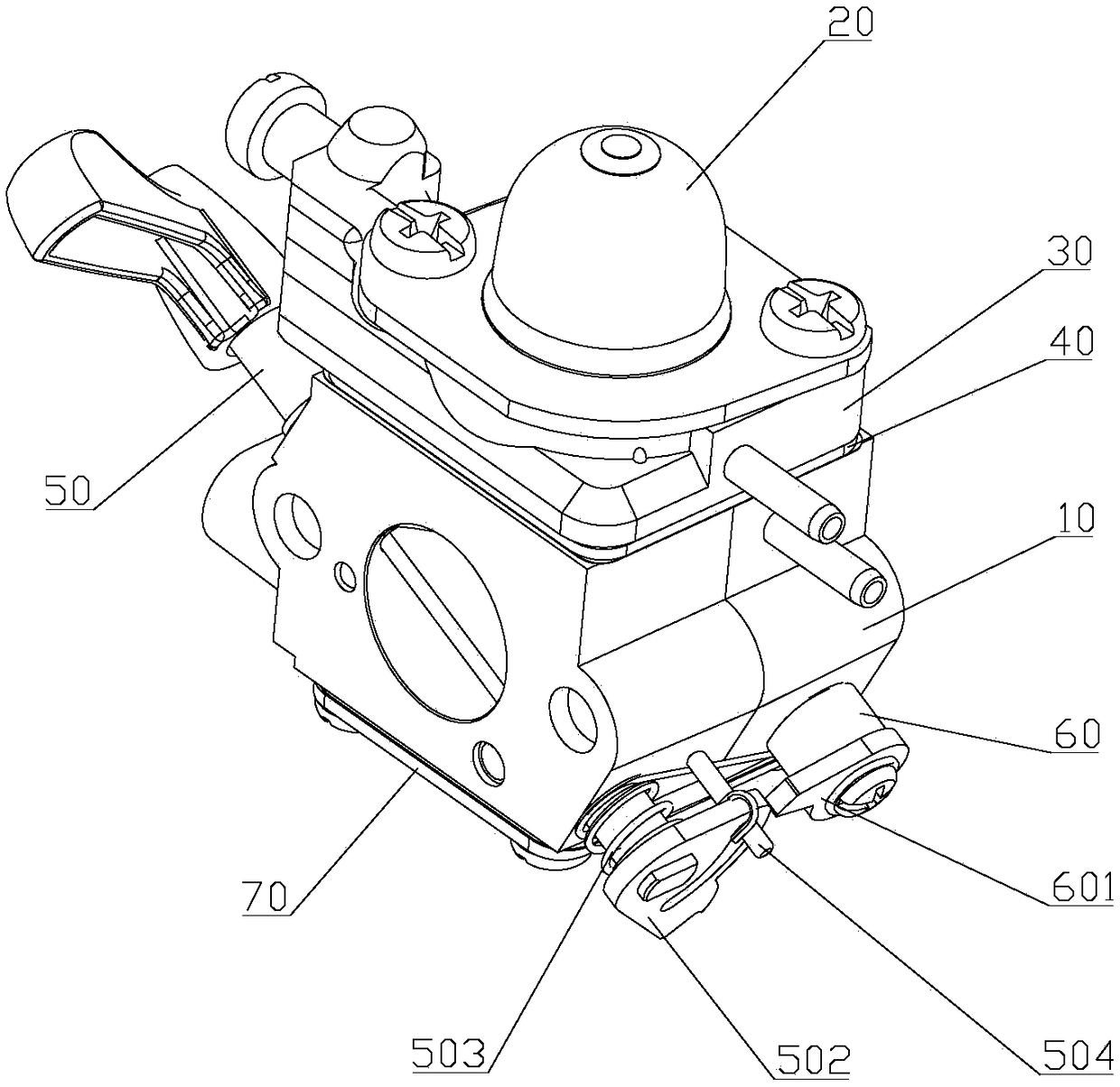

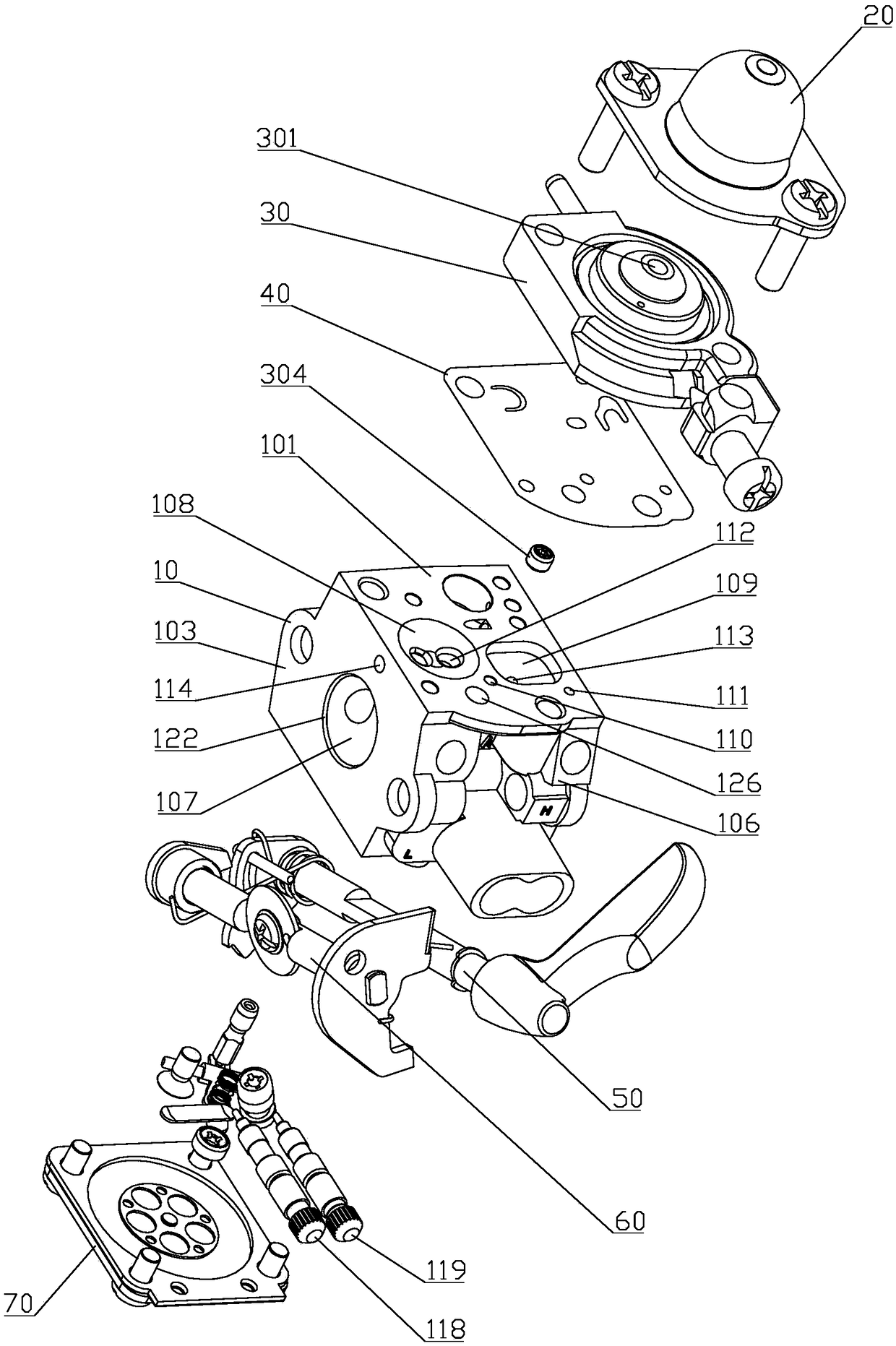

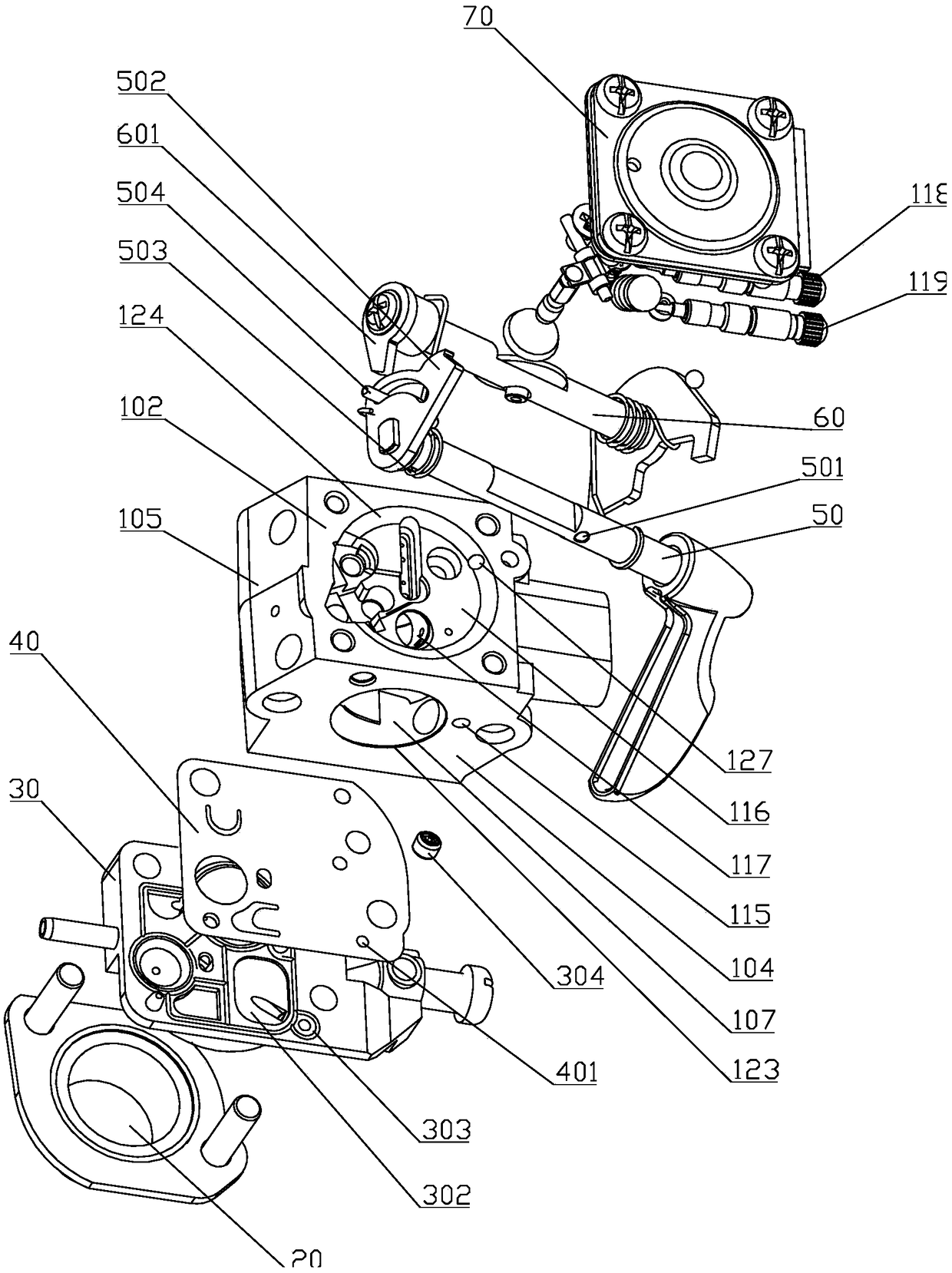

[0029] Such as Figure 1 to Figure 3 As shown, a carburetor with a new type of starting oil system includes an oil injector oil bubble 20, a pump cover 30, a pump diaphragm 40, a carburetor body 10, a starting shaft 50, a throttle shaft 60 and a metering chamber cover 70 . The carburetor body 10 is provided with a pump surface 101, a metering chamber surface 102, a throttle end surface 103, a choke end surface 104, an oil inlet connection surface 105, and a high and low speed nail surface 106, an oil injector oil bubble 20, a pump cover 30 and a pump membrane The pieces 40 are sequentially fixed on the pump surface 101 of the carburetor body 10 by bolts. The carbur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com