Feedthrough for gwr measurements in tanks

A feedthrough and storage tank technology, applied in the field of feedthroughs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0045] The disclosed embodiments are further illustrated by the following specific examples, which in no way should be construed as limiting the scope or content of the invention.

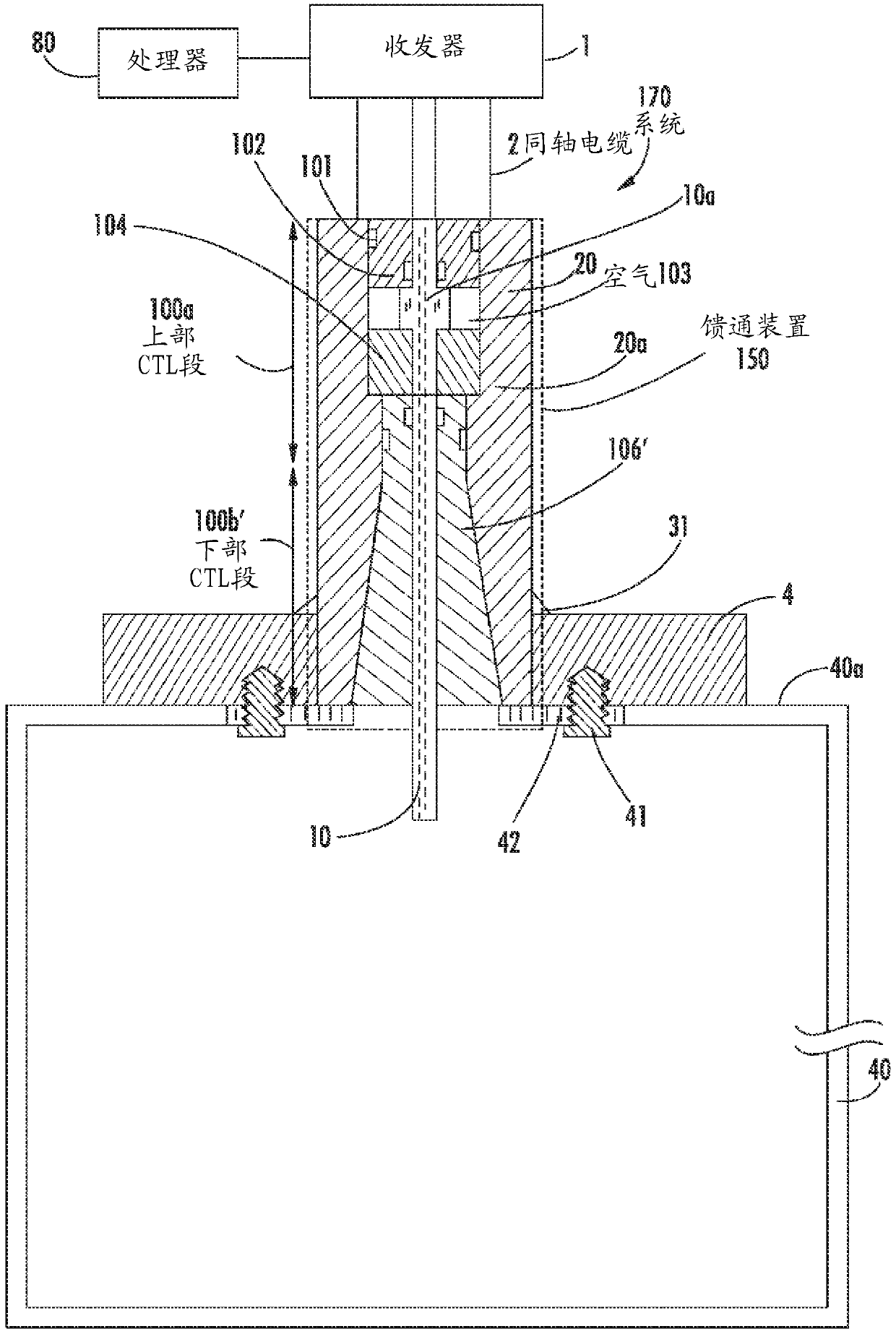

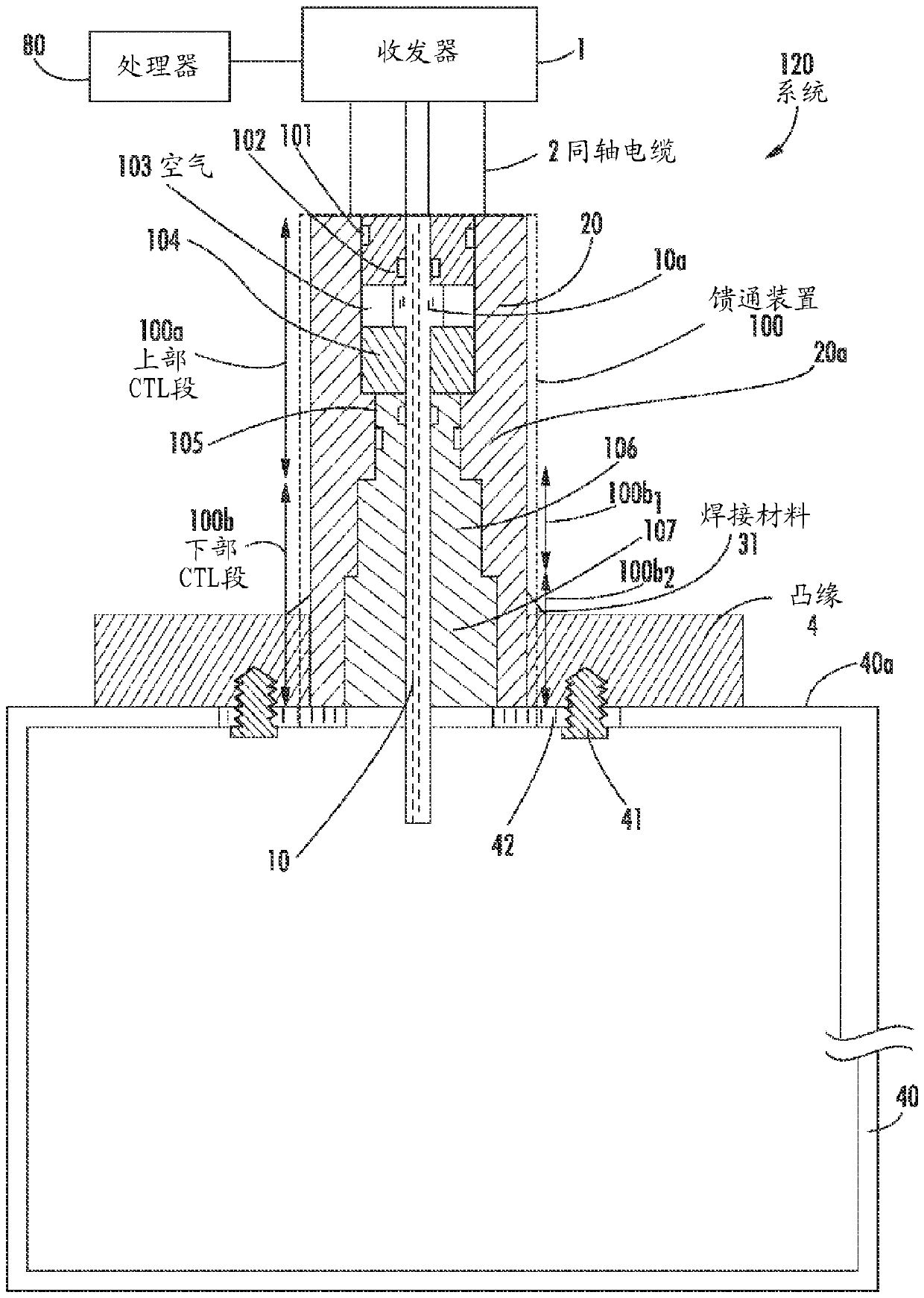

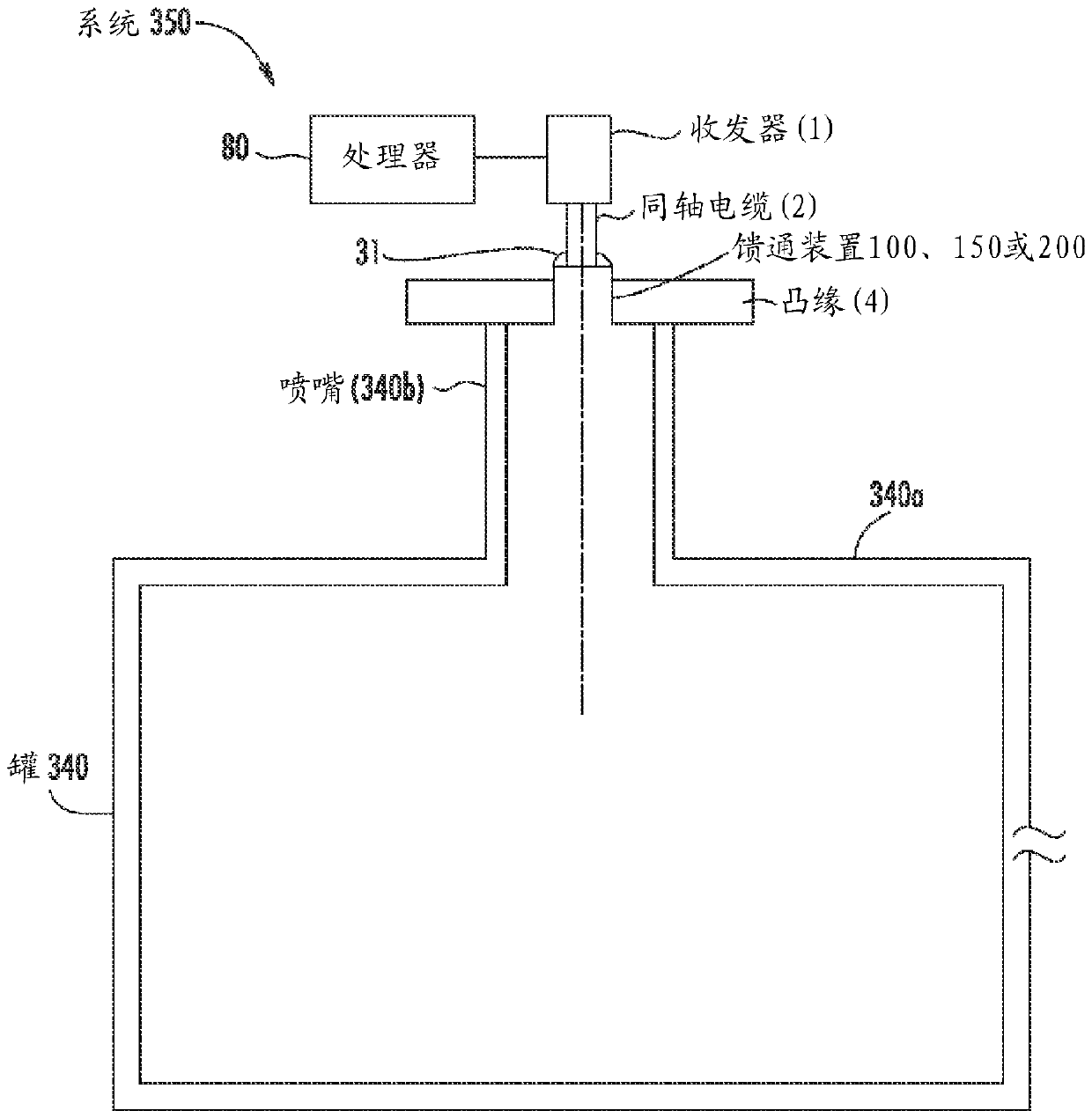

[0046] COMSOL simulation result data specific to time-domain reflectometry measurements is described below, showing an initial interrogation pulse with a peak value of 1.8 V and a half-maximum of 0.5 ns according to disclosed embodiments for different geometries of the feedthrough Full Width (FWHM), and an example of an echo (pulse) from the end of the feedthrough (flange location) and a metal target (ideal electrical conductor) located 1 m from the signal source (generating the aforementioned voltage peak) , the echo is a spurious echo. Between these two echoes, there may be other spurious echoes originating from multiple reflections from the end of the feedthrough and from the metal target. The simulation results compare the voltage echo obtained from the disclosed feedthrough with the voltage e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com