Component with measuring element with at least one sensor

A technology of measuring elements and sensors, which is applied to force sensors related to bearings, force sensors in holes of force-bearing structures, measuring devices, etc., can solve problems such as troublesome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

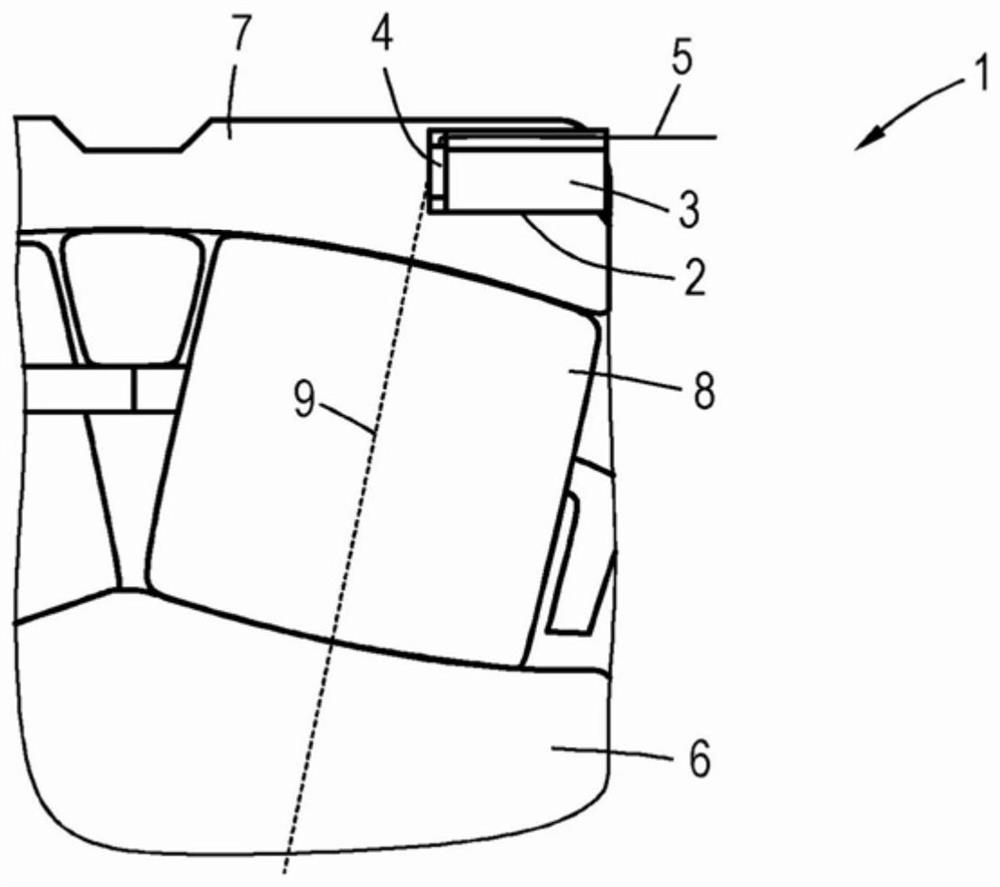

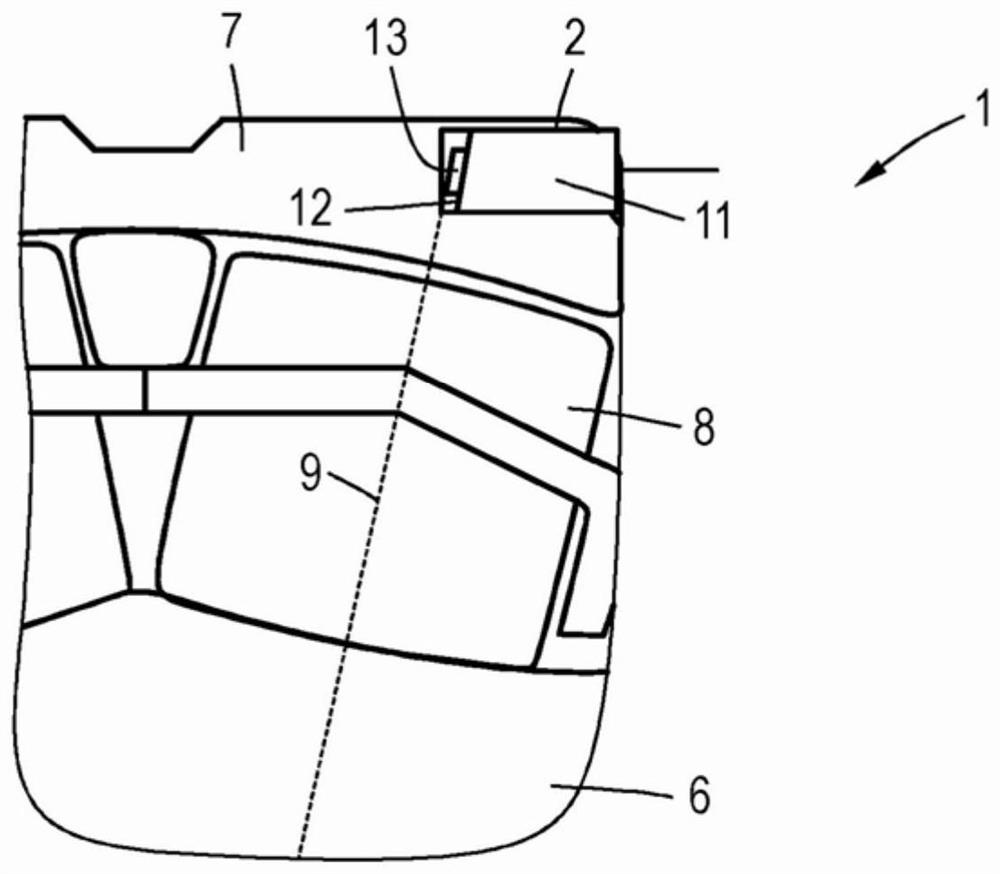

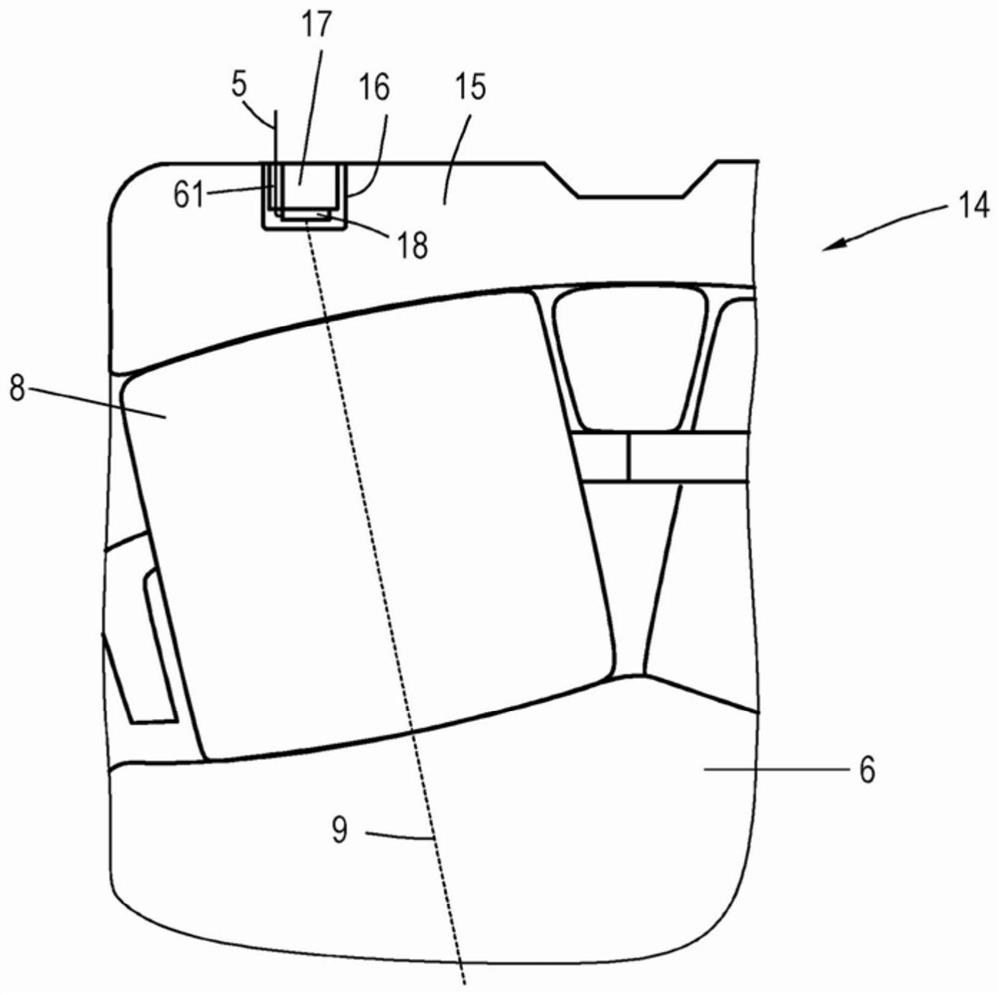

[0034] figure 1 A detail of a component 1 is shown, which is designed as a rolling bearing and has a cylindrical material recess 2 in which a measuring element 3 with a sensor 4 is located. The sensor 4 is designed as a strain gauge (DMS) and has a cable 5 which is connected to a measured value detection device.

[0035] The component 1 designed as a rolling bearing comprises an inner ring 6 , an outer ring 7 and rolling bodies 8 arranged therebetween. exist figure 1 It can be seen that the measuring element 3 is formed cylindrically or as a peg.

[0036] During the operation of the rolling bearing, the rolling bearing is loaded by external forces. exist figure 1 , the line of action 9 for the nominal contact angle is shown dashed. The sensor 4 is arranged on the measuring element 3 such that the measuring direction of the sensor substantially coincides with the line of action 9 of the contact angle. Correspondingly, the sensor 4 is located directly in the force flow (fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com