Train-braking impulse control method

A pulse control, train technology, applied in the direction of brakes, pneumatic brakes, brake transmission devices, etc., can solve the problem of inability to stabilize the exhaust air speed control, and achieve the effect of stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

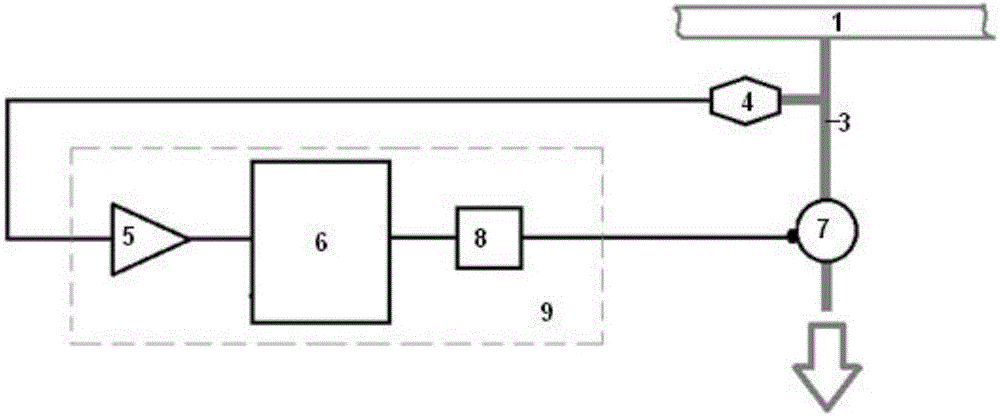

[0055] Such as figure 1 The illustrated embodiment is a pulse control method for train braking, comprising a train pipe 1 arranged on the train, a controller 2, a pipeline 3 communicated with the train pipe, a pressure sensor 4 arranged on the pipeline, and an AD conversion Device 5, processor 6, solenoid valve 7 and solenoid valve drive circuit 8 located at the rear of the exhaust port of the pipeline; the signal output end of the pressure sensor, AD converter, processor, drive circuit and solenoid valve are electrically connected in turn. connection; the controller is electrically connected to the processor; the AD converter, the processor and the drive circuit are all located in the train control vehicle-mounted device 9;

[0056] Including the following steps:

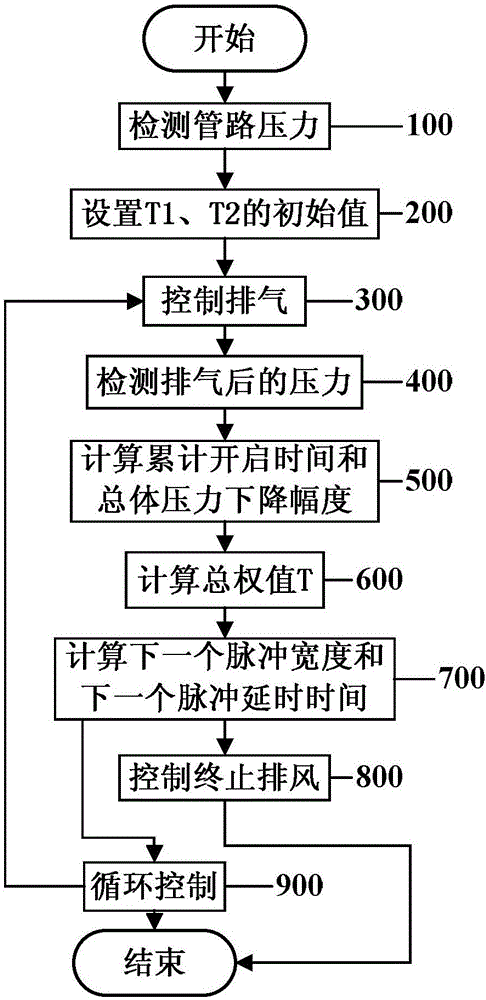

[0057] Such as figure 2 As shown, step 100, detecting pipeline pressure

[0058] The pressure sensor detects the pressure in the pipeline, the controller sends an exhaust command to the processor, and the proce...

Embodiment 2

[0084] Embodiment 2 includes all the structures and method parts of Embodiment 1, and Embodiment 2 also includes a microprocessor located between the pressure sensor and the first signal amplifier, and also includes the following steps:

[0085] In the microprocessor, the detection signal of the pressure sensor is processed as follows:

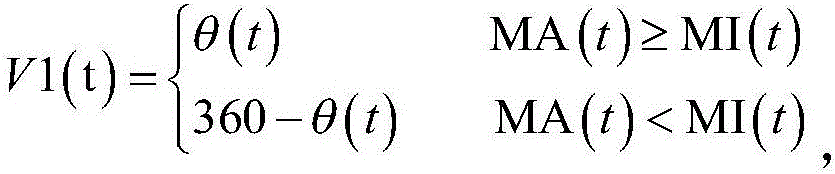

[0086] For each moment t in the detection signal, the computer calculates the voltage amplitude mean value VU(t), the voltage amplitude maximum value MA(t) and the voltage amplitude minimum value MI(t) from the time t-T to the time t;

[0087] set up

[0088]

[0089]

[0090]

[0091]

[0092] in,

[0093] The microprocessor sends the corrected detection signal V(t) to the first signal amplifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com