Sand suction method in non-central track bed area

A non-center, ballast bed technology, applied in the field of railway maintenance machinery, to achieve the effect of improving work efficiency, short disassembly and assembly time, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

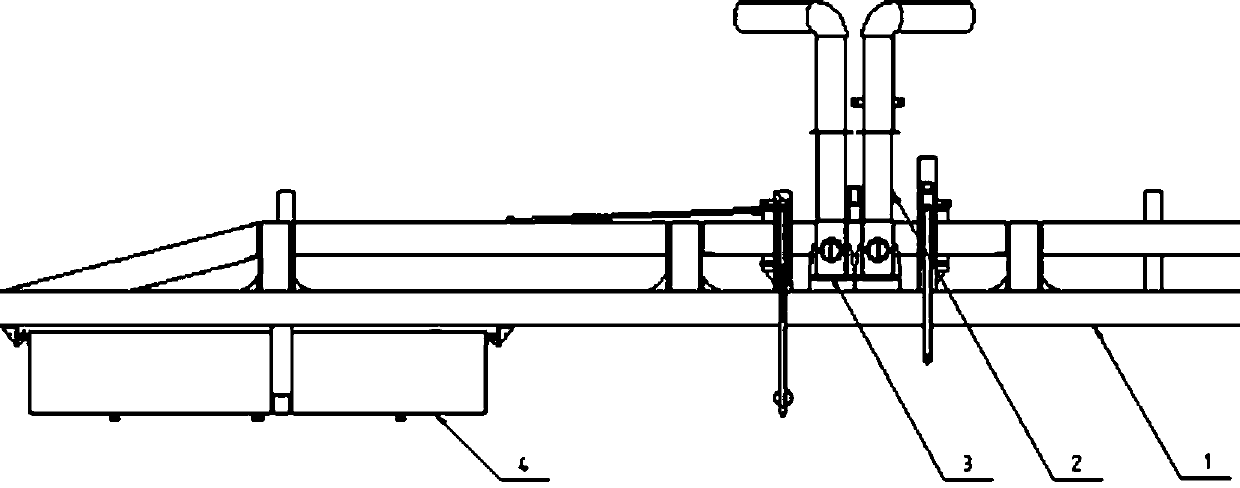

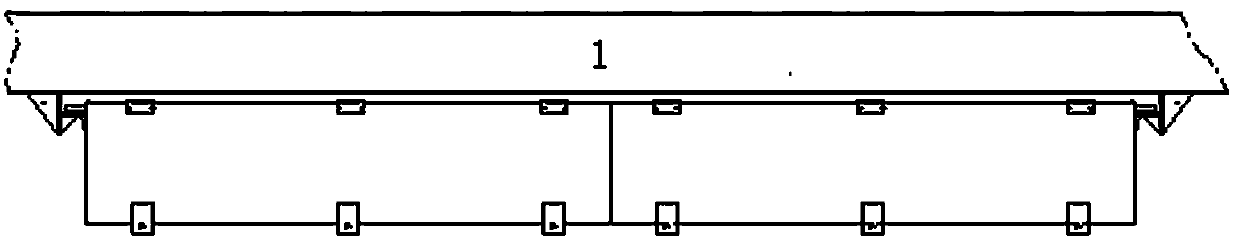

[0072] Embodiment 1.1, a method for sucking sand in a non-central ballast bed area, it comprises the steps:

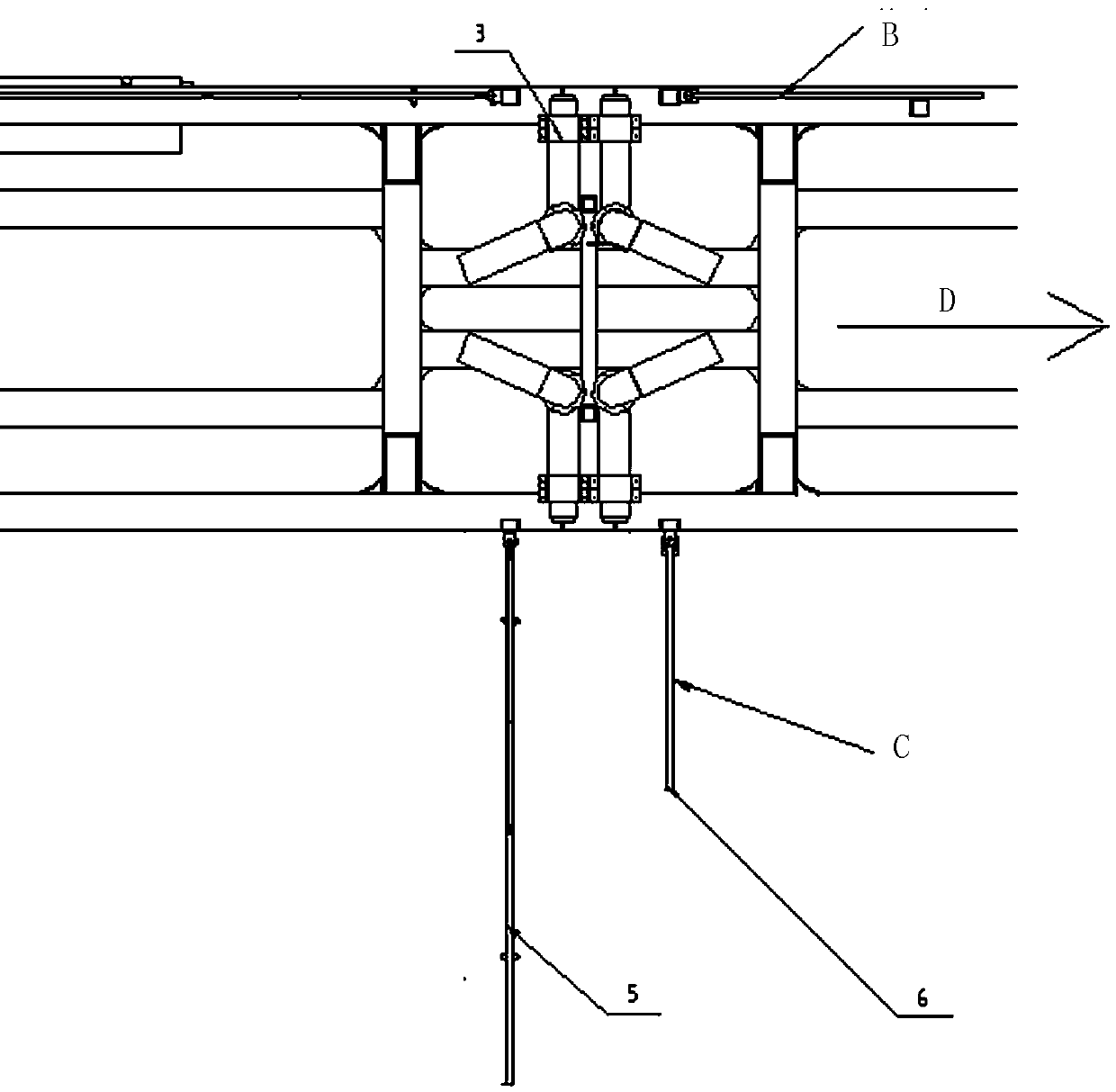

[0073] First. Walk the sand suction operation vehicle to the road section to be operated, install the hand-held suction pipe 12 of the 0-3m operation area and the middle suction pipe 14 and the hand-held suction pipe 13 of the 3-6m operation area according to the scope of the required operation, and put the long boom 5 and the short boom 6 are placed above the non-central ballast bed area;

[0074] 2. The operator enters the non-central ballast bed area that needs to be operated, and the operator in the 0-3m non-central ballast bed area controls the hand-held suction pipe 12 to make it in place through the handle;

[0075] Thirdly, the operator in the non-center track bed area of 3-6m sets the portable suction pipe 13 under the long boom 5 through the hanging hoop 39, so as to avoid deformation of the portable suction pipe 13 during operation;

[0076] 4. Rotate the...

Embodiment 12

[0092] Embodiment 1.2, the sand suction method in the non-central ballast bed area, is the same as Embodiment 1.1, except that the installation angle between the brush and the installation disk and the installation disk I is 45°.

Embodiment 13

[0093] Embodiment 1.3, the sand suction method in the non-central ballast bed area, is the same as Embodiment 1.1, except that the installation angle between the brush and the installation plate and the installation plate I is 40°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com