Glass fragment gathering device for automotive glass impact resistance experiment and method thereof

A technology of glass shards and automobile glass, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult manufacture of collection trays, affect the efficiency of experimental work, increase the amount of glass peeling, etc., achieve easy manufacture and use, and improve experimental efficiency , the effect of accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

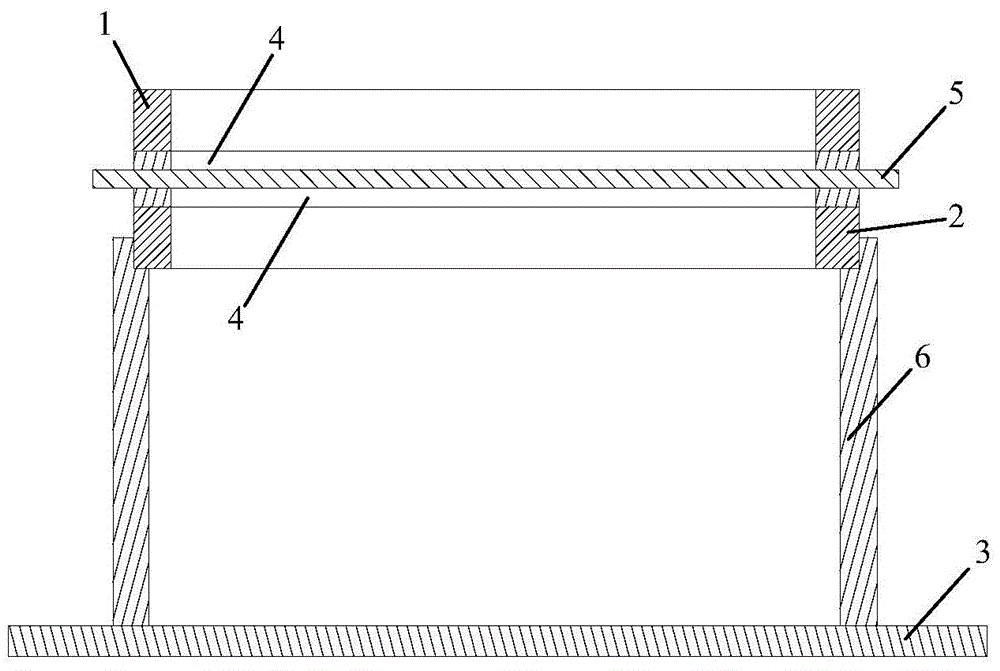

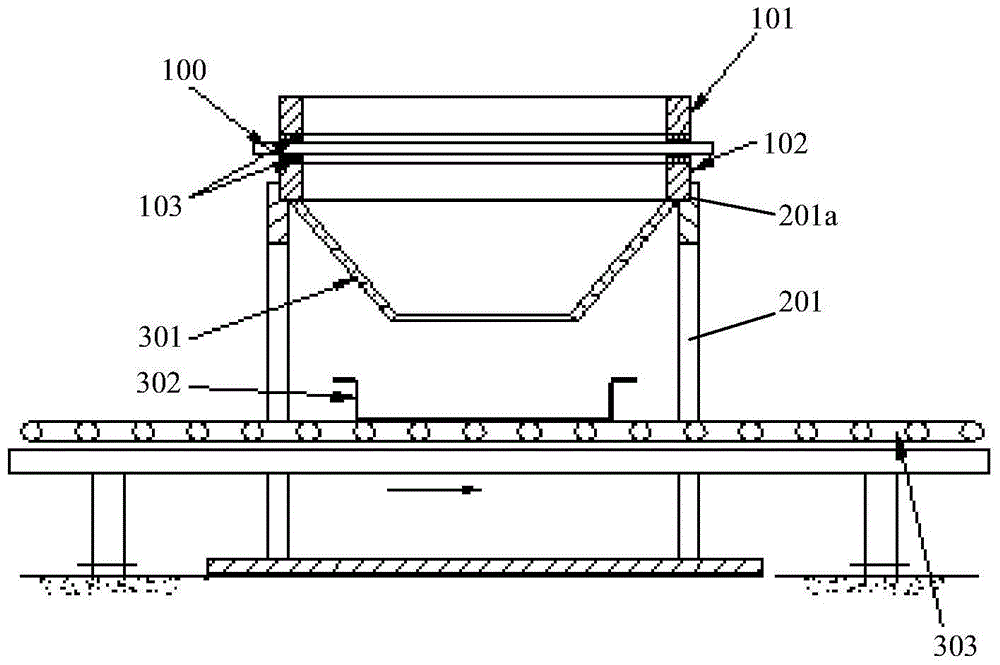

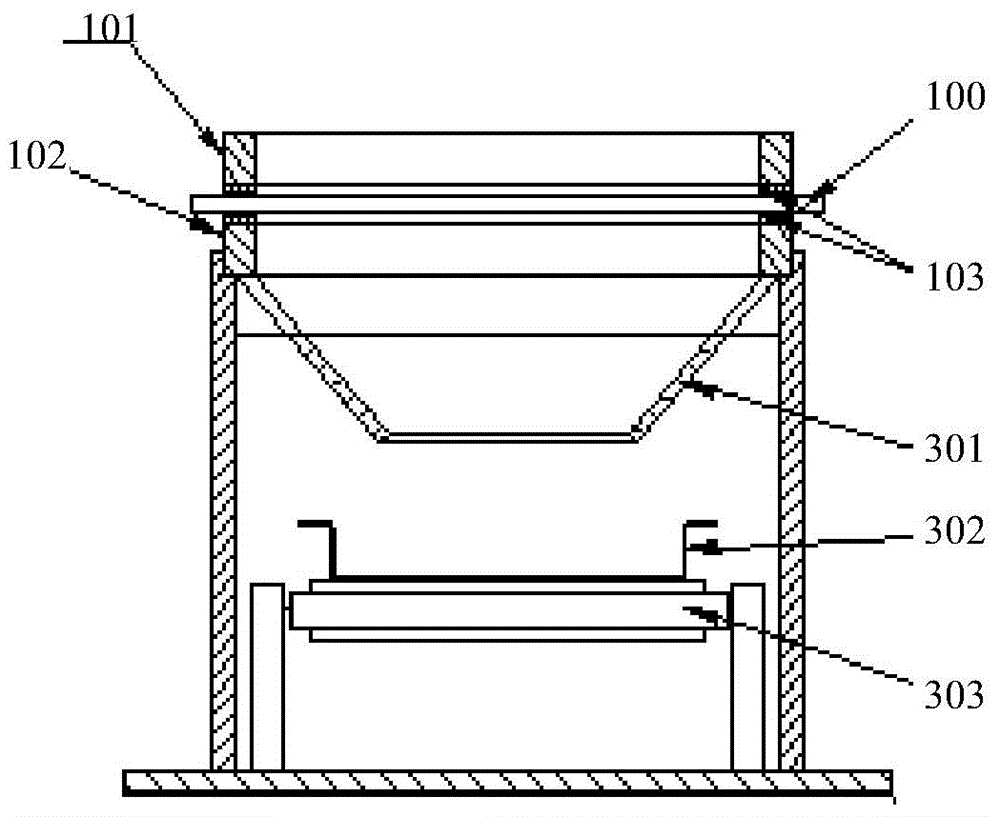

[0040] This embodiment provides a device for collecting glass shards in the impact resistance test of automobile glass, which includes a sample support part for supporting a horizontally placed glass sample to be tested, and a glass shard collection part for collecting glass shards. Specifically, as Figure 2-5 As shown, the sample support part is located above the glass fragment collection part, and includes: a clamping unit for clamping the glass sample to be tested and a support unit for supporting the clamping unit. The clamping unit includes an upper frame 101 and a lower frame 102, the glass sample 100 to be tested is clamped between the upper frame 101 and the lower frame 102, and the upper frame 101 and the lower frame 102 are connected to the glass sample to be tested. Rubber pads 103 are respectively arranged between 100 . The upper frame 101 and the lower frame 102 are square frames respectively, and the rubber pad 103 is used to play a buffering role when the uppe...

Embodiment 2

[0059] As an improvement to the first embodiment, the second embodiment only describes the funnel in detail, and other technical features are the same as those in the first embodiment, so no further description is given.

[0060] Such as Figure 9 As shown, the funnel 301 includes a square cone-shaped funnel body part 31 and a neck 32 connected to the lower end of the funnel body part 31; the left side wall 32a of the neck is bent radially inward and inclined to The bottom extends at least to directly above the bottom end 32b1 of the right side wall 32b of the neck.

[0061] When the glass sample is impacted, the stripped glass fragments will scatter and fall at a high speed. After the fragments fall into the funnel 301 , they are collected by the funnel body 31 and transported downward to the neck 32 . The neck 32 of the funnel is arranged as the above-mentioned structure, and the glass shards falling in all directions will not be directly ejected at high speed from the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com