Vehicle tires

A technology for pneumatic tires and vehicles, applied in vehicle parts, tire parts, tire treads/tread patterns, etc., can solve the problems of lack of lateral rigidity, no display of operating characteristics, etc., and achieve the effect of high lateral rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

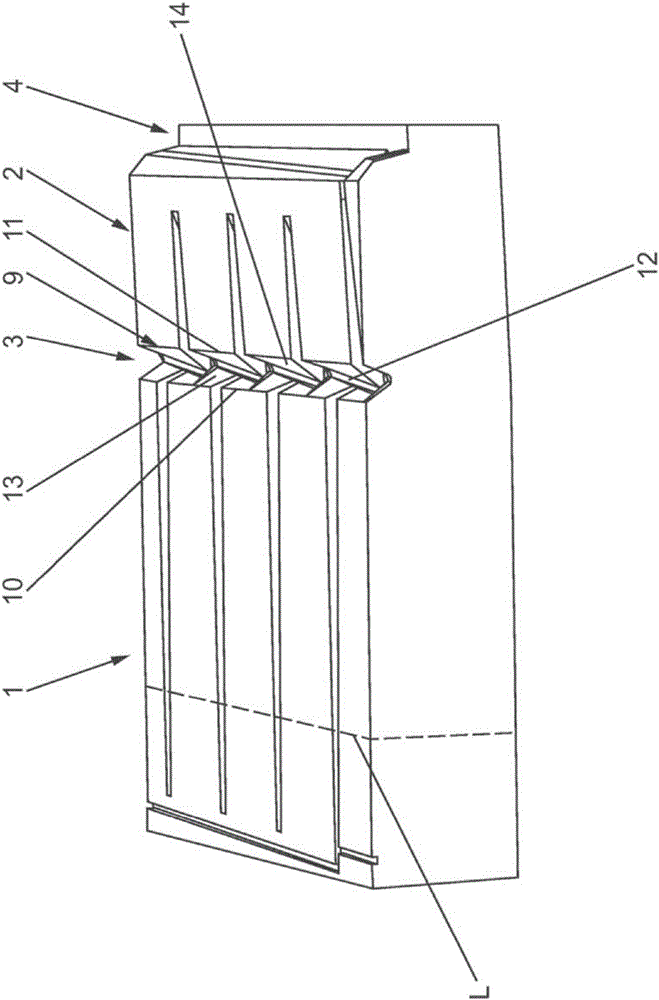

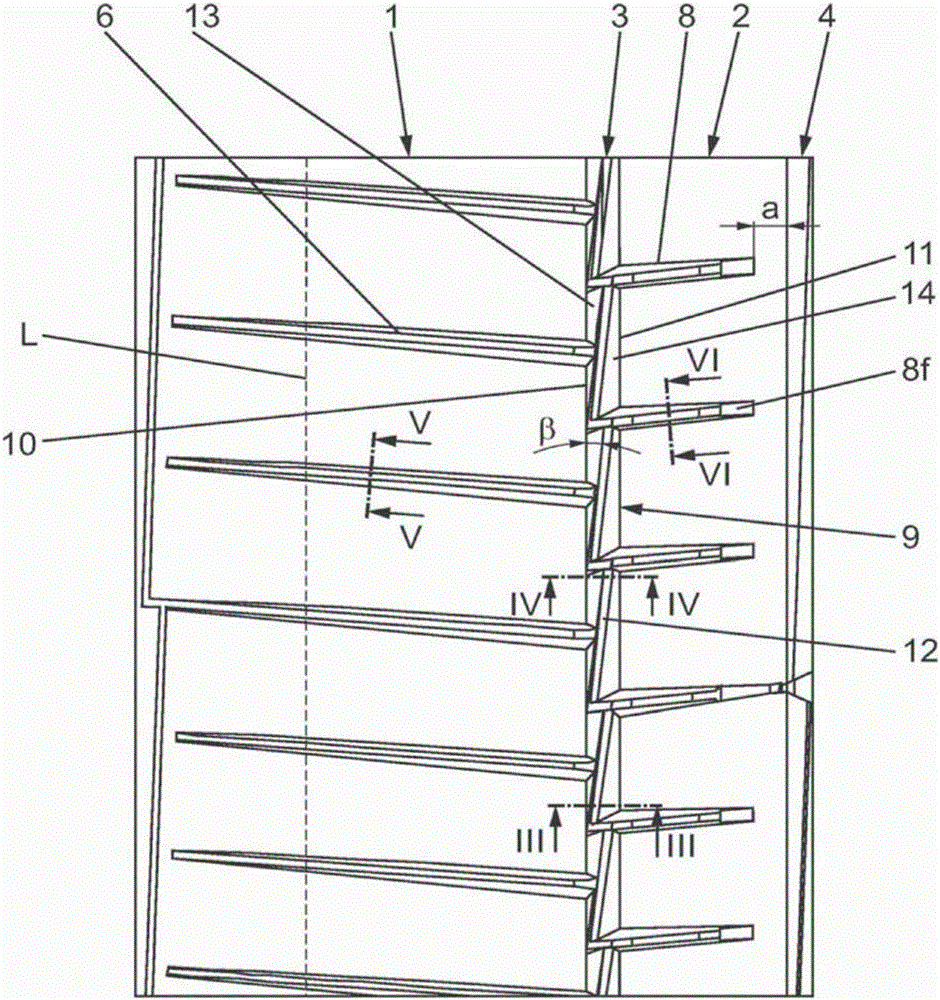

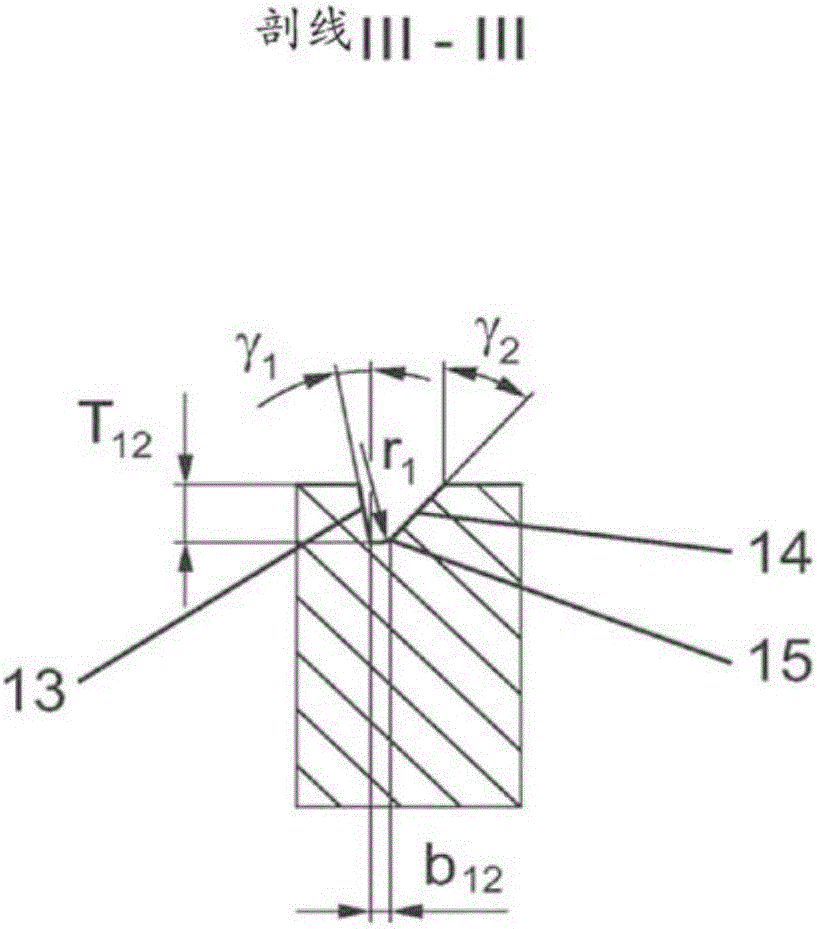

[0017] figure 1 and figure 2 A shoulder-side block row 1 and a block-structured tread band 2 are shown, particularly suitable for a vehicle pneumatic tire tread for passenger motor vehicles. The shoulder-side row of blocks 1 and the block-structured tread band 2 are arranged in particular in an outer subregion of a so-called “asymmetrical” tread pattern. Such tread patterns have, in the two tread halves, structurally differently configured profiles which are correspondingly implemented with respect to certain properties of the tire or tread. The shoulder-side row of blocks 1 is located at the outer shoulder of the tyre, which in a known manner is the shoulder-side area of the tyre, which is at the tire mounted on the vehicle Visible at the outside of the vehicle. exist figure 1 and figure 2 The line L indicated in row 1 of blocks on the shoulder side of the tread marks the edge of the tread, more precisely the edge of the ground-contacting or ground-supporting surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com