Biological fermentation liquor dewatering device and using method thereof

A technology of biological fermentation and fermented liquid, applied in separation methods, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of increasing production costs and consuming large energy, and achieve flexible use, high controllability, and reduced The effect of loss volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

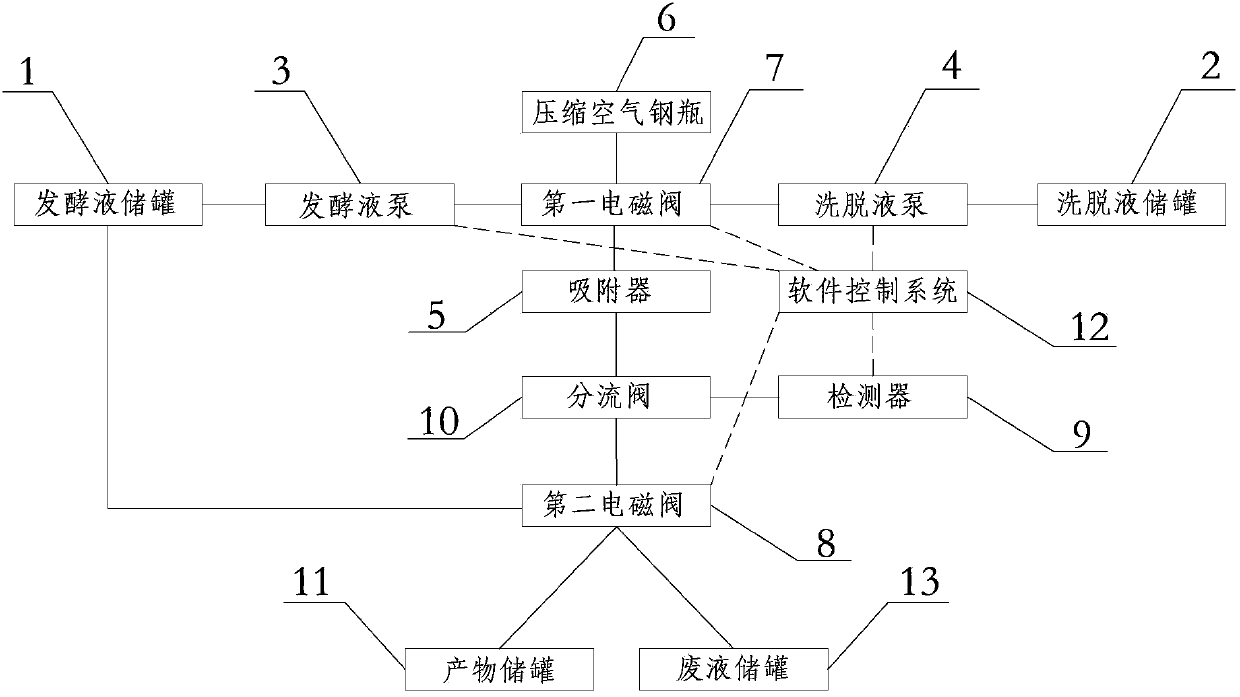

[0025] Adjust the first solenoid valve 7 and the second solenoid valve 8 so that the fermented liquid storage tank 1, the fermented liquid pump 3, the adsorber 5 and the waste liquid storage tank 13 form a path, open the fermented liquid pump 3, 1000ml of fermented liquid at a rate of 5ml / min The flow rate passes through the adsorber 5, and the effluent from the adsorption column 5 is split through the split valve 10 with a split ratio of 1:50. When the chromatographic peak appears in the detector 9, an instruction is sent by the software control system 12 to close the fermented liquid pump 3, adjust the first electromagnetic valve 7 and the second electromagnetic valve 8 to make the compressed gas cylinder 6, the adsorber 5, and the fermented liquid storage tank 1 A passage is formed, and the gas in the compressed gas cylinder 6 blows the residual fermentation liquid in the adsorber 5 back into the fermentation liquid storage tank 1 at a flow rate of 3 ml / min. When a sharp bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com