Pneumatic blockage cleaning device for sand storage bucket of casting finished product sand and using method of device

A sand storage bucket and finished product technology, which is applied in foundry molding equipment, machinery for cleaning/processing of mold materials, and manufacturing tools, etc., to ensure the effect of sand cleaning, mechanical sealing, and smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

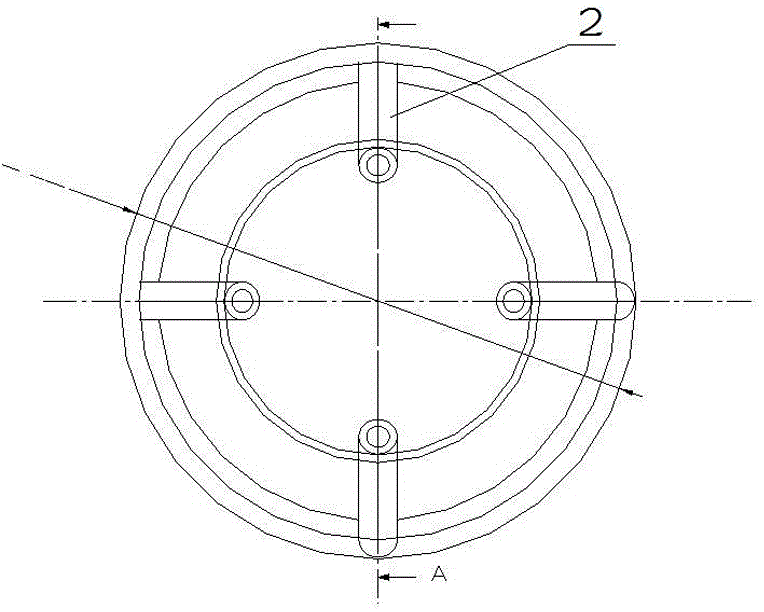

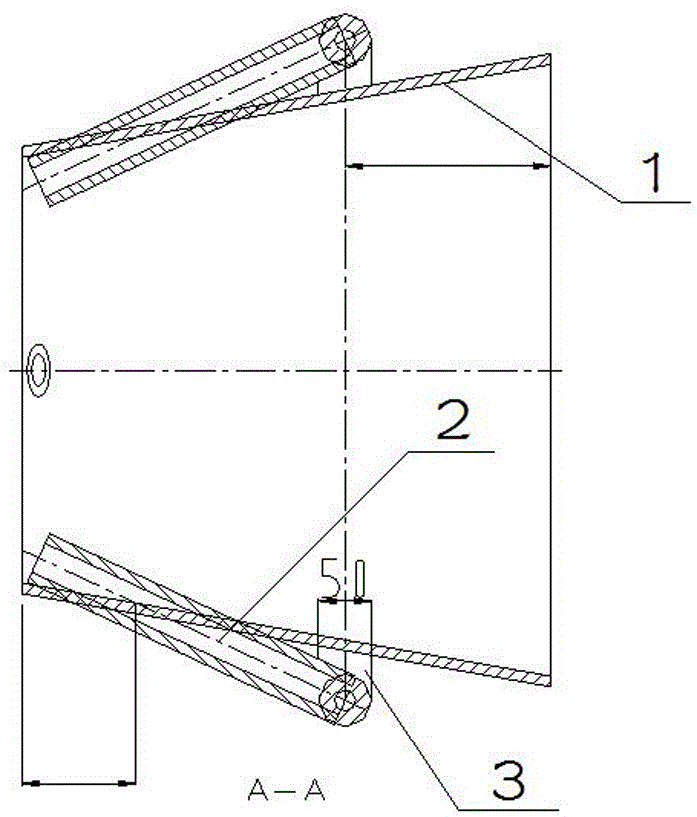

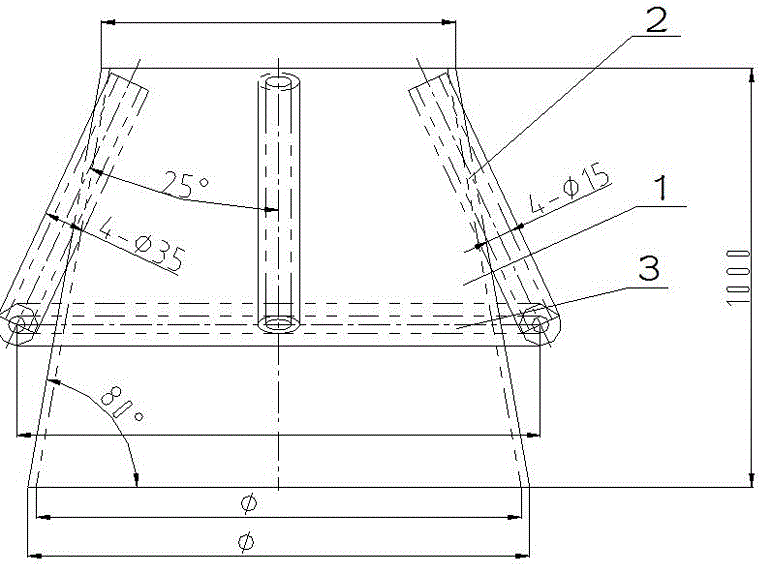

[0028] like Figures 1 to 3 As shown, a pneumatic unclogging device for finished casting sand storage hoppers provided in this embodiment includes a sand storage hopper 1 with a conical structure. The upper sand inlet of the sand storage hopper 1 is larger than the lower sand outlet, and it also includes four Hollow pipes 2 and four hollow pipes 2 are equally spaced along the circumference of the sand storage bucket;

[0029] The four hollow tubes 2 pass through the outer wall of the sand storage bucket 1 respectively, and the included angles between the four hollow tubes 2 and the outer wall of the sand storage bucket 1 are the same, and the distance between the junctions of the four hollow tubes 2 and the outer wall of the sand storage bucket 1 is The height of the falling sand opening under the sand bucket 1 is the same, and the center delay lines of the four hollow tubes 2 all point to the falling sand opening of the sand storage bucket 1, because the center delay lines of...

Embodiment 2

[0032] This embodiment provides a method of using a pneumatic unclogging device for sand storage hoppers of cast finished products. In actual production, the lower sand drop opening of the sand storage hopper 1 is connected to the square sand discharge opening, so the blocking of the sand storage hopper 1 The place is the transitional surface between the lower sand falling port and the square sand discharging port. When the sand discharging system is blocked, open the air supply valve to fill the annular hollow pipe 3 with high-pressure gas, and the annular high-pressure gas passes through the 4 hollow pipes 2 to the lower falling port. High-pressure cleaning is performed at the transitional surface between the sand mouth and the square sand outlet; the air supply pressure of the air supply valve is 0.6-0.8Mpa, and the duration of high-pressure cleaning is 2-3 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com