Variable-thickness and ultralarge-size three-dimensional paper cutting method based on 3D printing

A super-large size, 3D printing technology, applied to special patterns, patterns characterized by contours, decorative art, etc., can solve the problems of low boundary strength, tidal color, singleness, etc., achieve multi-space visual impact, and meet rapid production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

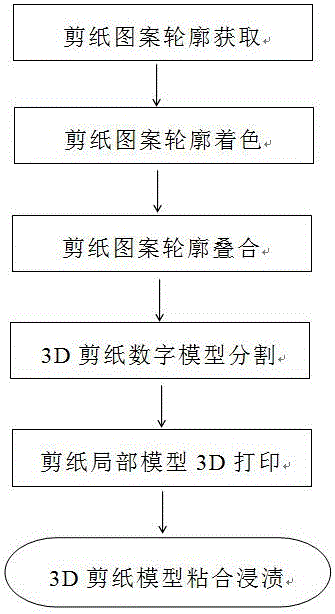

[0019] see figure 1 , the present invention provides a variable-thickness super-large-size three-dimensional kirigami method based on 3D printing. The method is to color the designed kirigami pattern outline layer by layer and stack it into a 3D kirigami digital model with a positive dislocation strategy, and use a paper-based 3D color printer. The finished products made under specific process parameters are further bonded and impregnated to form super-sized three-dimensional paper-cut crafts. The positive dislocation strategy refers to the method of arranging the layer with a larger outline area in the superimposed paper-cut pattern of each layer adjacent to the bottom layer.

[0020] The 3D printing-based variable-thickness super-large-size three-dimensional paper-cutting method includes the following steps:

[0021] 1) Obtain the outline of the kirigami pattern, use AI software and other vector software to design the kirigami pattern, or directly scan traditional kirigami ...

Embodiment 2

[0028] The difference from the first embodiment above is that: in step 4), the cut surface of the local 3D model bonded is a convex curve boundary, then in step 6), the temperature in the constant temperature chamber is 42°C, and the glue-coated sheet is The pressing time of the partial 3D model is 12s, the further pressing time of the partial 3D model is 12 minutes, the pressure of the pressing operation is 240N, and the waiting time for the dipping and curing treatment is 8 minutes.

Embodiment 3

[0030] The difference from the first embodiment above is that: in step 4), the cut surface bonded by the local 3D model is a straight line boundary, then in step 6), the temperature in the constant temperature chamber is 36°C, and the glue-coated sheet is locally The pressing time of the 3D model is 10s, the further pressing time of the partial 3D model is 9 minutes, the pressure of the pressing operation is 200N, and the waiting time of the dipping and curing treatment is 6 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com