A method for loading super-long steel materials on railway flat cars

A railway flatbed and super-long technology, which is applied in motor vehicles, transportation and packaging, and vehicles for freight transportation, etc., can solve the problems of high transportation costs, high logistics costs of super-long steel, and lag in the business of super-long steel. , to achieve the effect of ensuring stability, reducing logistics costs, and ensuring transportation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in combination with specific embodiments.

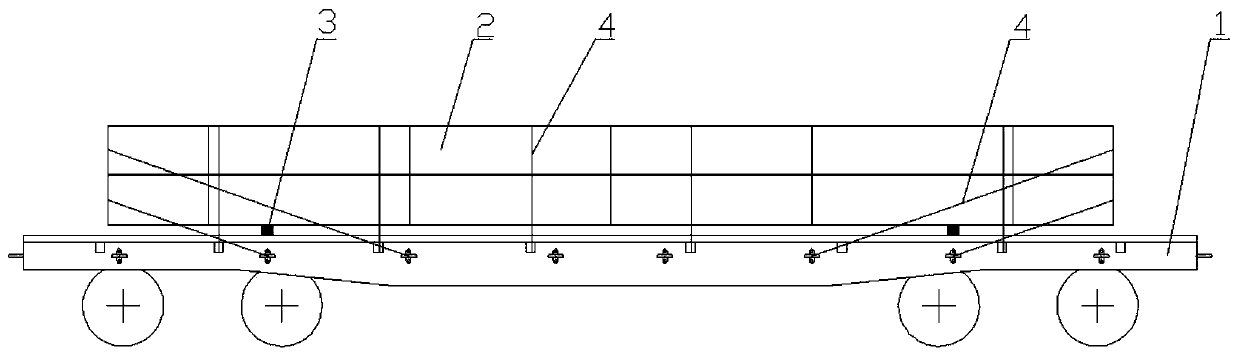

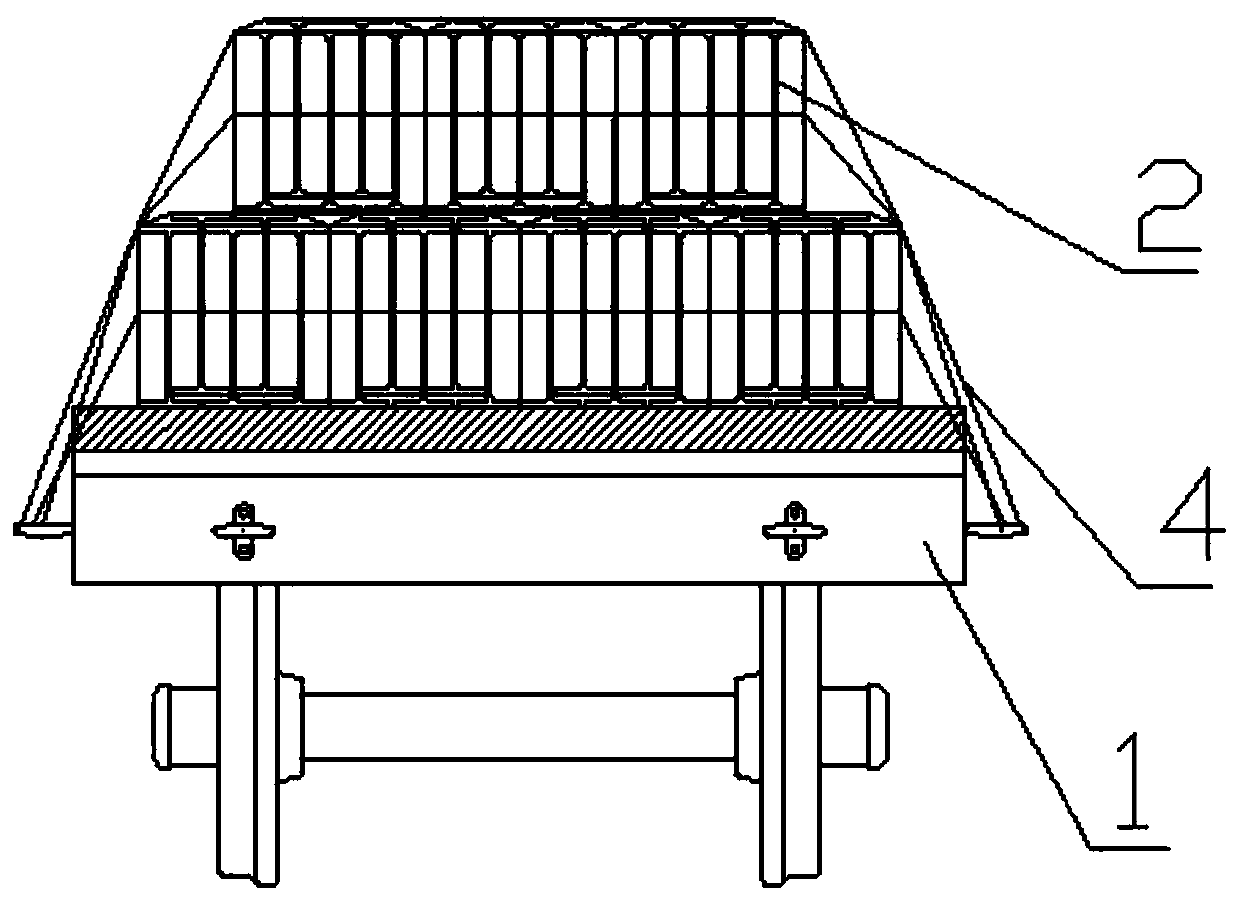

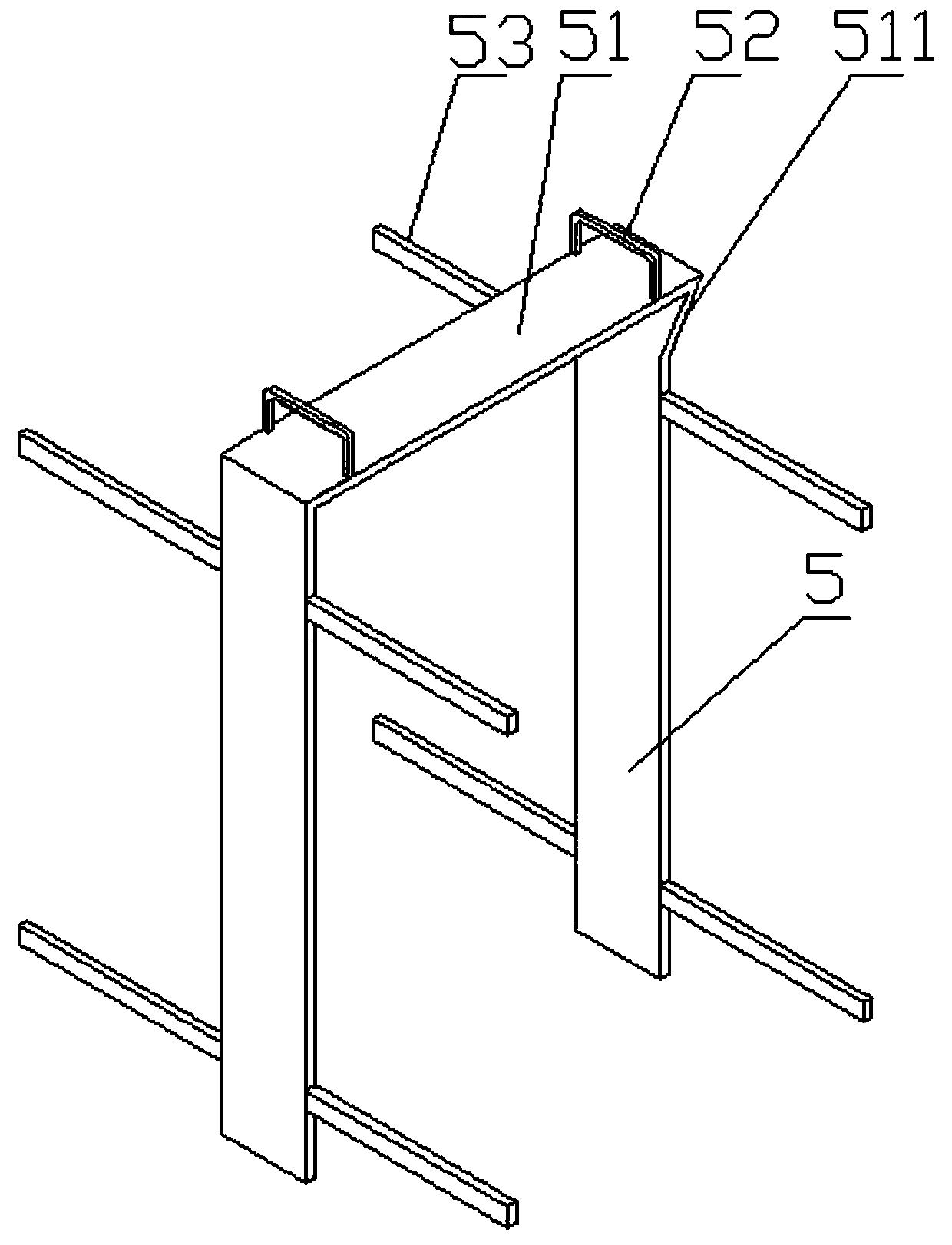

[0019] Depend on figure 1 , figure 2 , image 3 As can be seen, a method for loading super-long steel products of a railway flat car is characterized in that the loading method is carried out according to the following steps:

[0020] A. Steel bundling: use the bundling material to bundle the super-long steel 2 according to a certain number;

[0021] B. Bottom laying: After cleaning the bottom plate of railway flatbed car 1, lay two horizontal skids 3 on the bottom of the car, the distance between the two horizontal skids 3 is k, 9000mm≤k≤15000mm, on both sides of the horizontal skids 3 The bottom plate of the car is covered with straw mats, and the height of the straw mats after being compacted is matched with the height of the cross skids 3;

[0022] C. The first layer of steel loading: the super-long steel 2 is hoisted and placed on the horizontal skid 3, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com