Locomotive air braking system and locomotives

An air brake and locomotive technology, applied in the field of vehicles, can solve problems such as the inability to guarantee the safe use of large-tonnage locomotives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

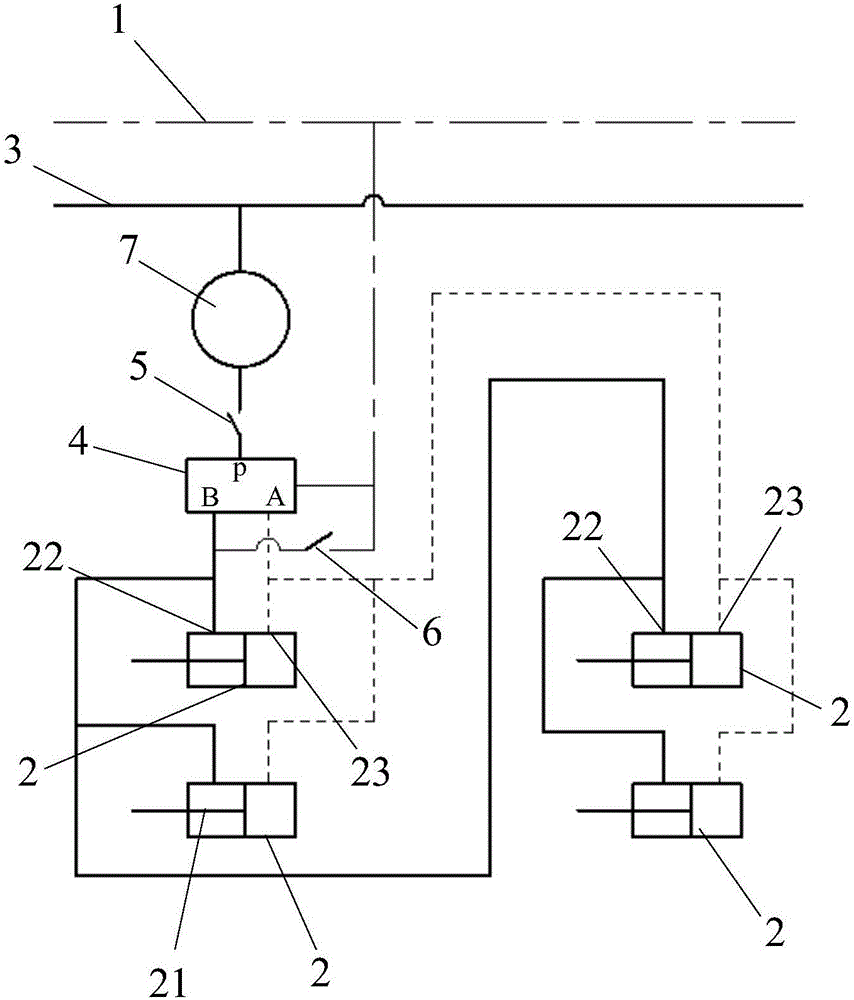

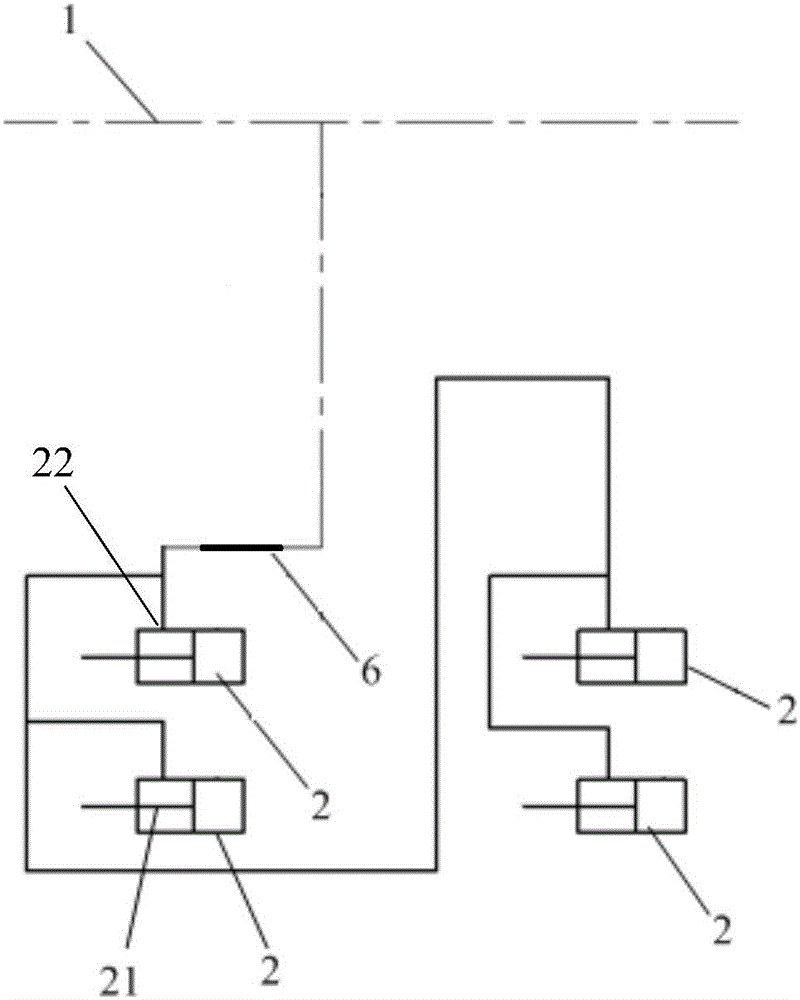

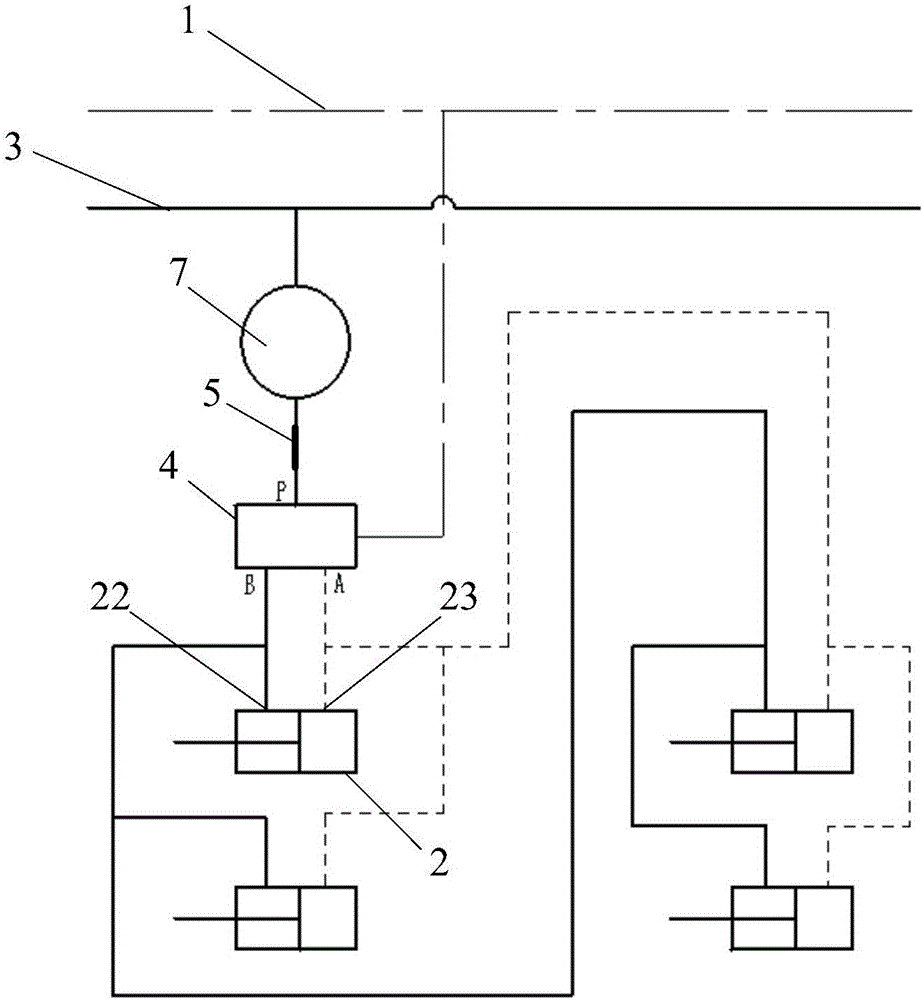

[0030] figure 1 It is a schematic structural diagram of a locomotive air brake system provided by an embodiment of the present invention. refer to figure 1 As shown, this embodiment provides an air brake system for a locomotive, including: a brake cylinder 2, and a control air duct 1 communicating with an air compressor (not shown in the figure). Specifically, the air compressor is connected to the traction locomotive, and the traction locomotive is used to supply power to the air compressor, and the compressed air of the air compressor is used to supply air to the control air duct 1 . In a specific implementation, a control device (not shown in the figure) may be provided between the air compressor and the control air duct 1 , and whether the air compressor supplies air to the control air duct 1 is controlled by the control device.

[0031] The brake cylinder 2 includes a cylinder body and a piston 21 located in the cylinder body. The piston 21 divides the cylinder body int...

Embodiment 2

[0042] This embodiment provides a locomotive, which includes a car body and an air brake system arranged on the car body.

[0043] The structure and principle of the air brake system in this embodiment are the same as those of the locomotive air brake system provided in Embodiment 1, and can achieve the same technical effect, so details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com