Rotating disc type suction nozzle bottle packaging machine

A carousel type, packaging machine technology, applied in the directions of packaging, transportation and packaging, the type of packaging items, etc., can solve the problem of no packaging material conveying and manufacturing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below according to specific embodiments.

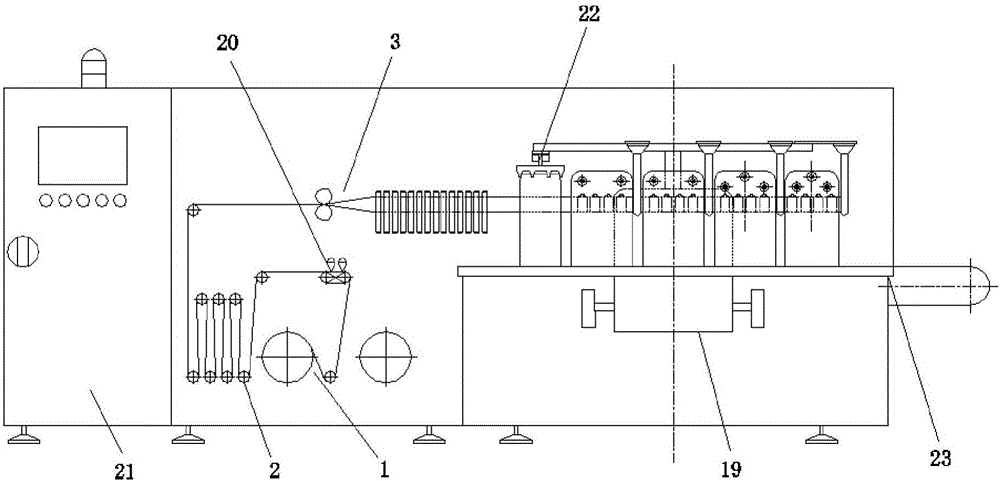

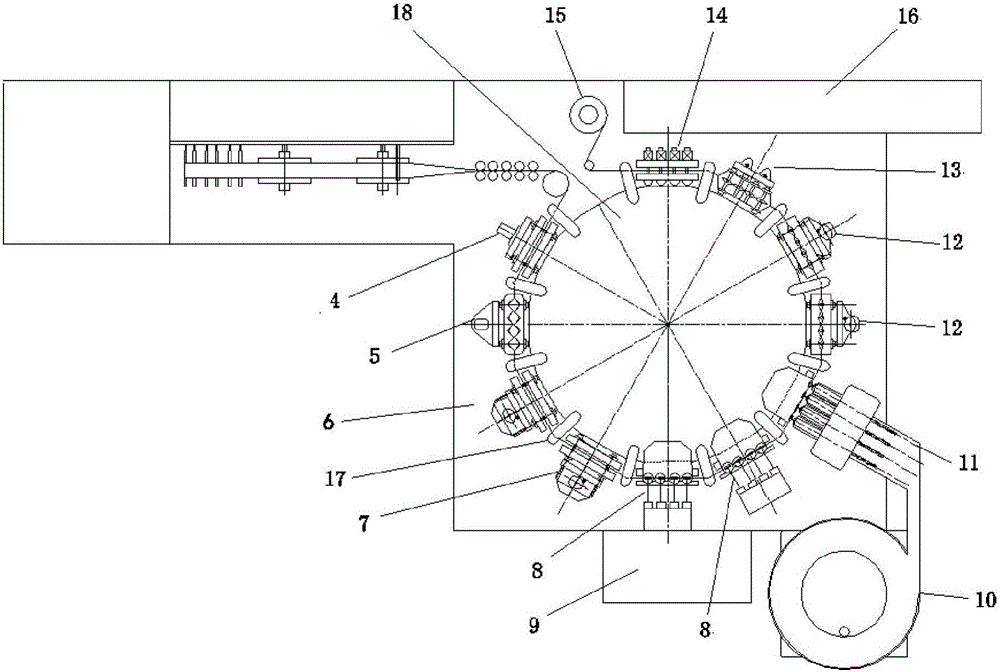

[0023] Such as Figure 1-2 As shown, a turntable suction nozzle bottle packaging machine includes a packaging material unwinding device 1, a packaging material connecting device 20, a packaging material buffer device 2, a stacking device 3, a turntable conveying device 18, and a finished product conveying device 16 connected in sequence. , clamping devices 17 are evenly distributed on the circumference of the tray conveying device 18, and preheating devices 4, forming devices 5, heat sealing devices 6, forming cooling devices 7, filling Filling device 8, mouth adding device 11, mouth sealing device 12, mouth cooling device 13 and finished product separation device 14, air blowing device 22 is provided above molding device 5, fluid storage bin 9 is connected to filling device 8, A suction nozzle screening device 10 is connected to the nozzle adding device 11 , and a residual mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com