Production method and device for suction nozzle bottle and suction nozzle bottle

A production method and technology of a production device, which are applied in the field of suction bottles, can solve the problems of packaging materials with no barrier design, cannot be repeatedly opened, sealed, and cannot be resealed, etc., and achieve a high level of hygiene and safety, low cost, and production process. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

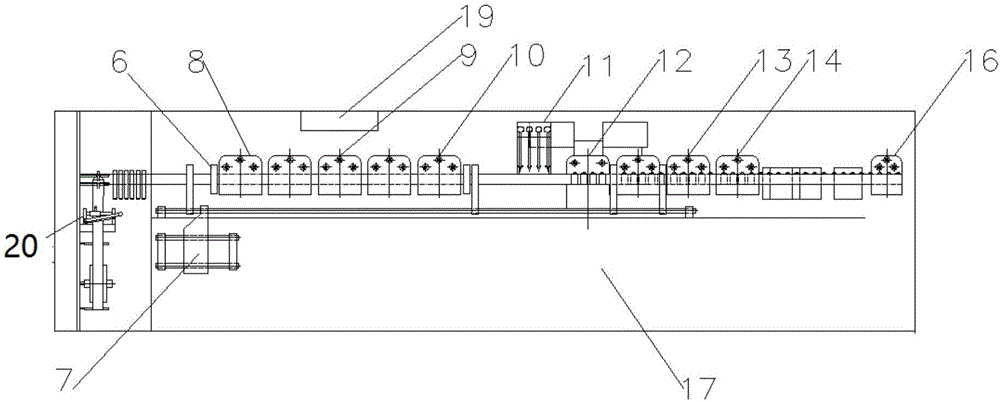

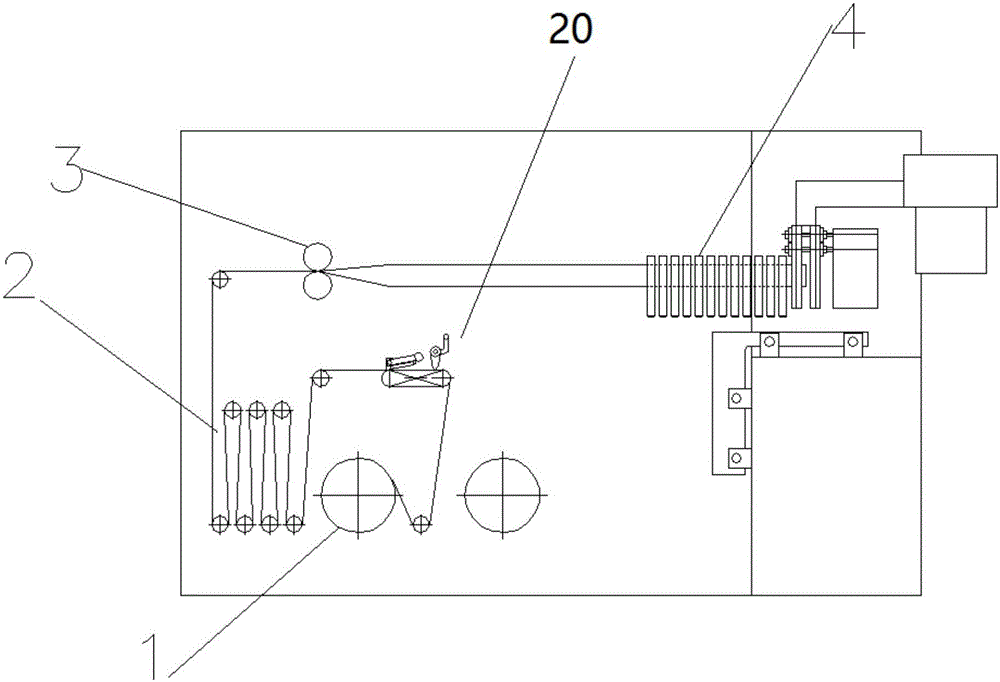

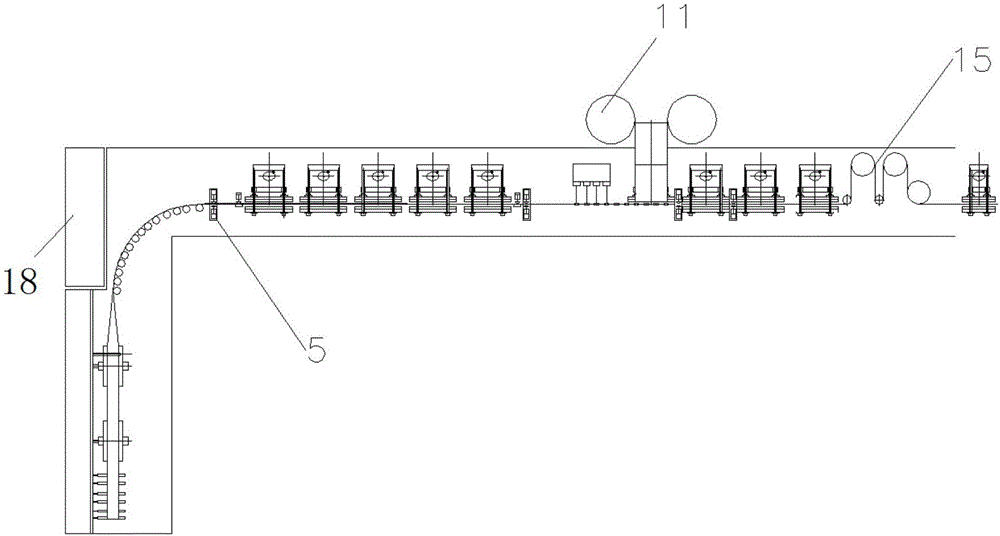

[0055] A production method of a suction bottle, comprising the following steps:

[0056] 1) Take the hard sheet as the raw material, and after folding a piece of raw material in V shape, define it as the packaging material;

[0057] 2) Use direct contact to heat the packaging material to soften it, the heating temperature is 80°C, and the heating time is 1.3s;

[0058] 3) Use the heated mold to heat seal the edge of the packaging material and leave a vent hole. The temperature of the mold is the heat sealing temperature; when the packaging material is softened, blow air through the vent hole to make the packaging material into a bottle shape , the bottle type is limited by the shape of the mold; the heat-sealing temperature is 80°C, the heat-sealing time is 1.3s, and the blowing pressure is 0.75Mpa;

[0059] 4) Cool the package material blown into bottle shape until finalized;

[0060] 5) After the packaging material is blown into shape, add a suction nozzle to the vent hole...

Embodiment approach 2

[0064] A production method of a suction bottle, comprising the following steps:

[0065] 1) With the hard sheet as the raw material, after superimposing two separate raw materials, it is defined as the packaging material;

[0066] 2) Use indirect contact to heat the packaging material to soften it, and reserve ventilation holes at the edge of the packaging material. The heating temperature is 260°C and the heating time is 0.1s;

[0067] 3) Add a suction nozzle to the air hole. The material of the suction nozzle is compatible with the packaging material, that is, the molecules have interpenetration after hot melting; the suction nozzle has the function of repeated opening and sealing;

[0068] 4) Use the heated mold to press and fasten the overlapping area between the suction nozzle and the packaging material on both sides of the packaging material, so that the packaging material and the suction nozzle can be sealed in the fastening area. The shape of the mold and the suction n...

Embodiment approach 3

[0073] A production method of a suction bottle, comprising the following steps:

[0074] 1) Take the hard sheet as the raw material, and after folding a piece of raw material in V shape, define it as the packaging material;

[0075] 2) Use direct contact to heat the packaging material to soften it, the heating temperature is 150°C, and the heating time is 0.6s;

[0076] 3) Use the heated mold to heat seal the edge of the packaging material and leave a vent hole. The temperature of the mold is the heat sealing temperature; when the packaging material is softened, blow air through the vent hole to make the packaging material into a bottle shape , the bottle shape is limited by the shape of the mold; the heat-sealing temperature is 195°C, the heat-sealing time is 0.6s, and the blowing pressure is 0.65Mpa;

[0077] 4) Cool the package material blown into bottle shape until finalized;

[0078] 5) After the packaging material is blown into shape, add a suction nozzle to the vent h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com