Electrolysis product mixing device, ballast water treatment device, ship, suctioning and mixing device and electrolysis product mixing method

A mixing device and product technology, applied in water treatment devices, water/sewage treatment, natural water treatment, etc., can solve difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, an electrolytic product mixing device according to one embodiment of the present invention will be described with reference to the drawings.

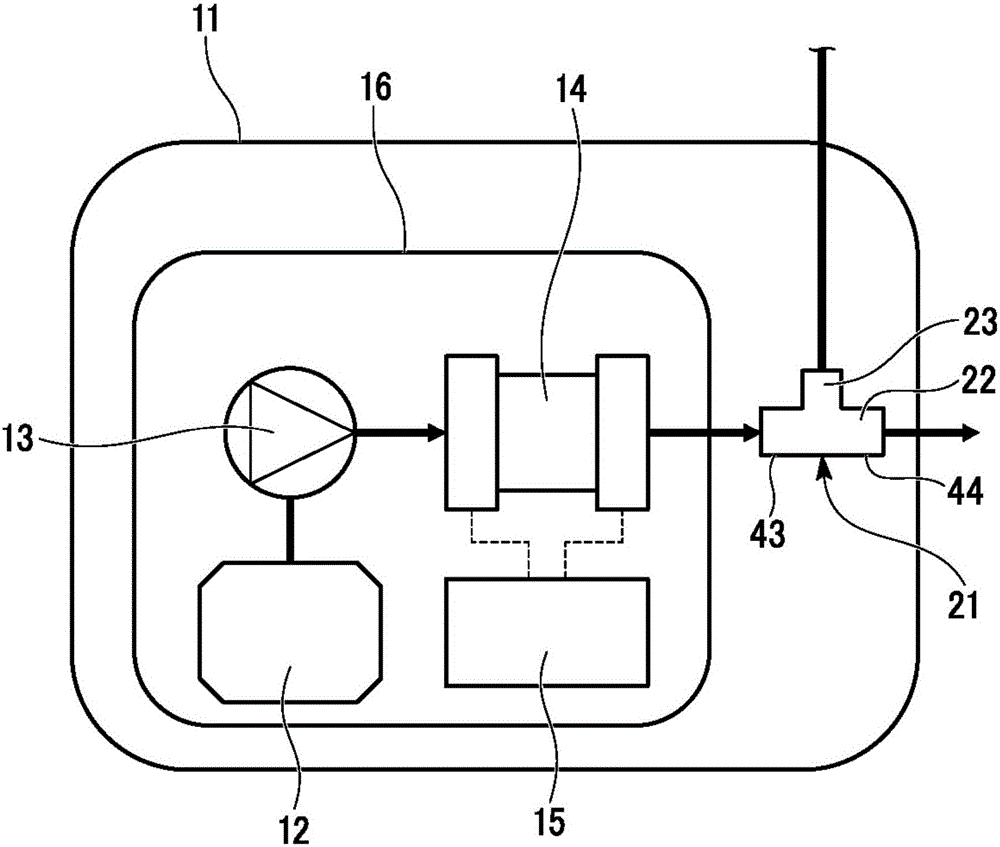

[0047] like figure 1 As shown, the electrolytic product mixing device 11 of this embodiment has an electrolytic module 16, and the electrolytic module 16 has: an electrolytic solution tank 12 that stores an electrolytic solution; an electrolytic solution; an electrolytic cell 14 into which the electrolytic solution ejected from an electrolytic solution pump 13 can be introduced; and an electrolytic power source 15 which supplies electric power to the electrolytic cell 14 . The electrolytic cell 14 electrolyzes the electrolytic solution using electric power supplied from the electrolysis power source 15 .

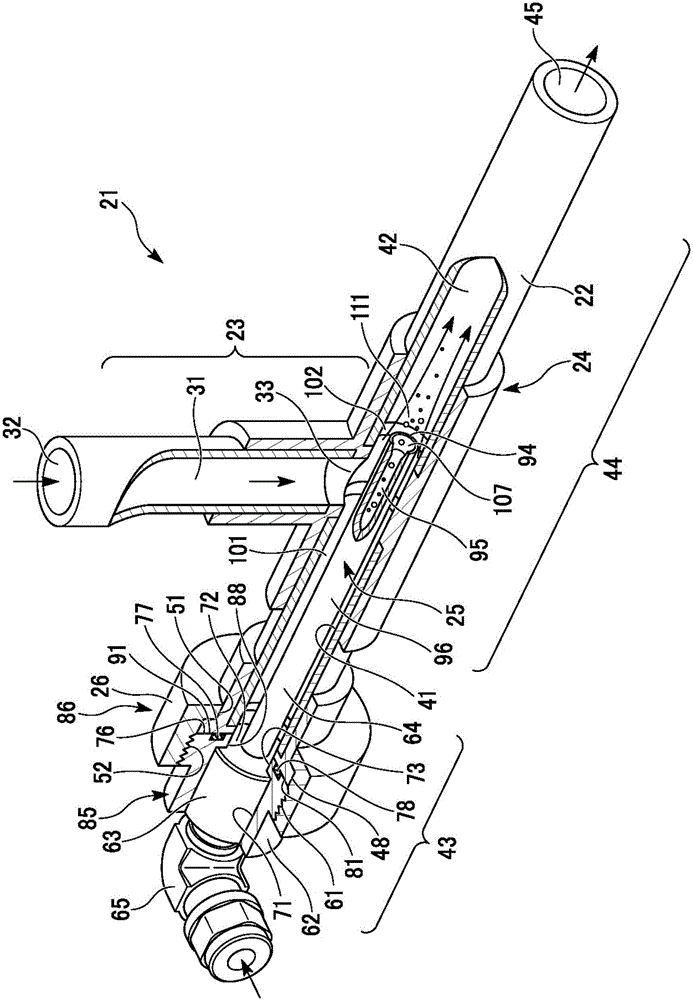

[0048] The electrolytic product mixing device 11 has a suction mixing device 21 into which the raw water is pressurized and introduced, and the suction mixing device 21 sucks the electrolytic product generated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com