Leakage repairing and reinforcement internal management structure of constructed external wall and construction method

A construction method and technology for exterior walls, applied to building structures, walls, building components, etc., to achieve the effects of long service life, no need for formwork, and simple construction techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

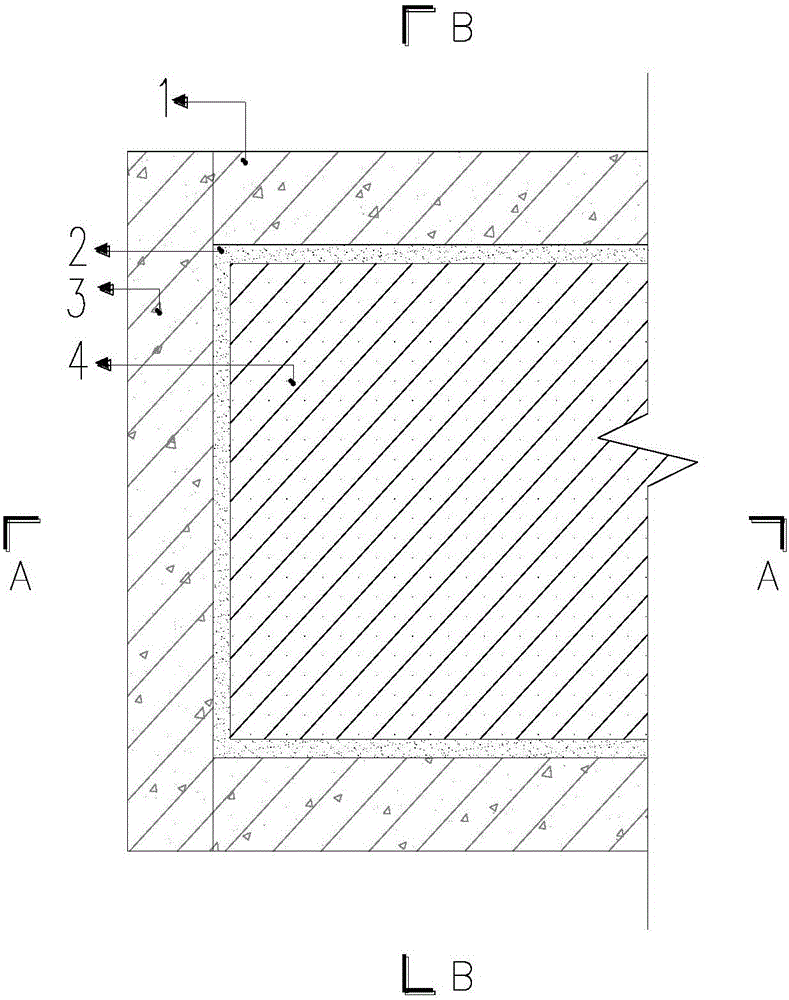

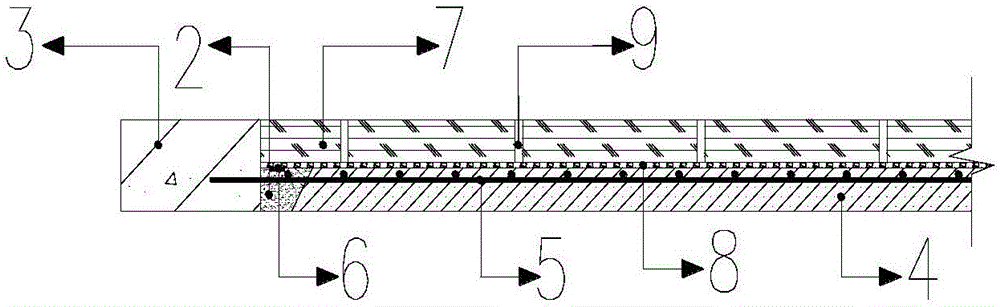

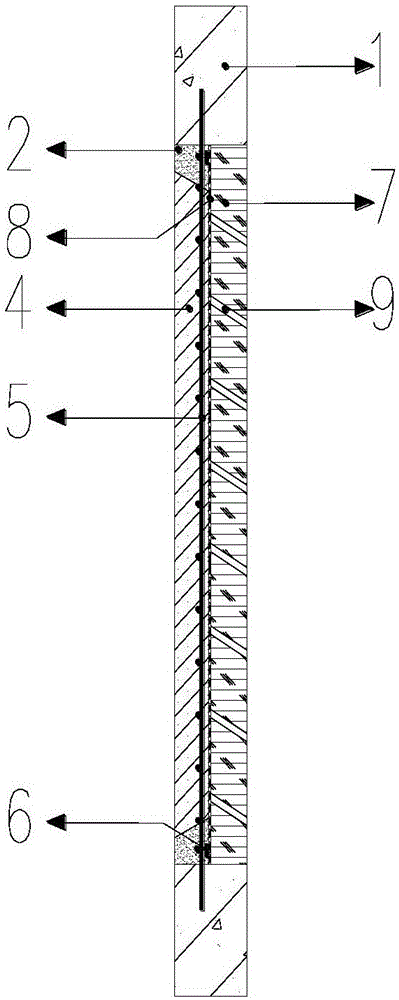

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as Figure 1-3 As shown, a leak-trapping and strengthening internal treatment structure for the external wall of the structure includes beam (ring beam) 1, leak-stopping agent 2, column (structural column) 3, hand-dropped early-strength impermeable concrete 4, and implanted steel bar 5 , rubber waterstop 6, structural exterior wall 7, cement-based permeable crystal 8, inclined hole 9;

[0034] The inner side of the outer wall 7 of the structure is chiseled to a thickness of 10 to 15 cm on the inner surface, and the leaking position is temporarily stopped, and for the non-basement outer wall, an oblique hole 9 is drilled on the wall to drain the water from the outside low and the inside high; clean the base, paint Brush the cement-based infiltration crystal 8; then paste the water-swellable rubber waterstop strip 6 in the chiseled w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com