Aeroengine pipeline vibration testing device and method

An aero-engine and vibration testing technology, which is applied in the direction of engine testing, vibration testing, measuring devices, etc., can solve problems such as uncontrollable excitation sources and single test working conditions, and achieve test cost savings, reliability assurance, and optimized management. The effect of road assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

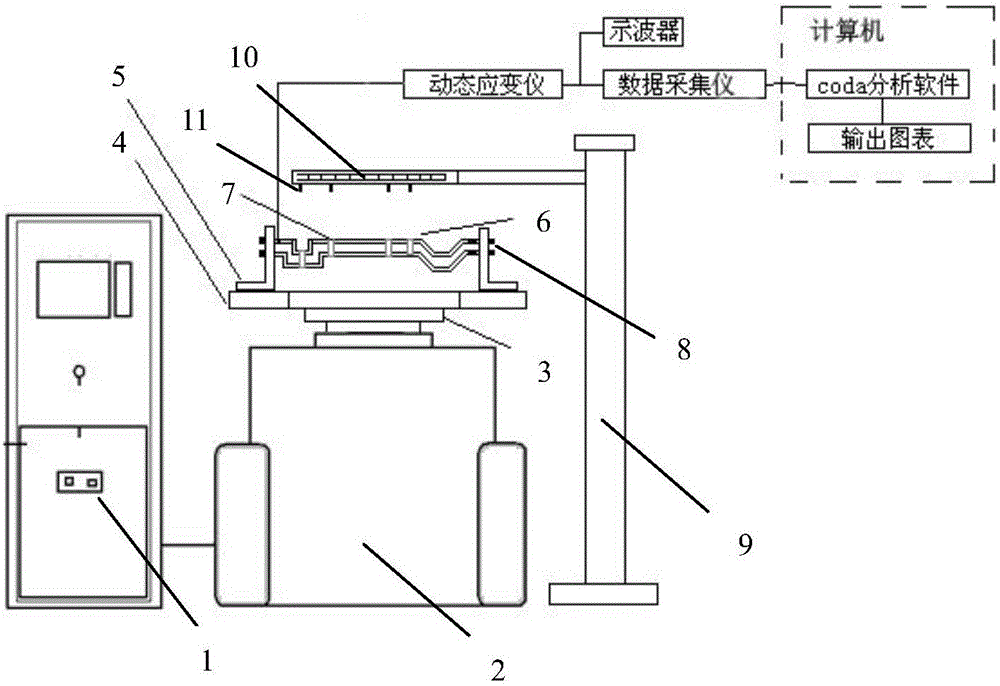

[0050] This embodiment provides an aero-engine pipeline vibration testing device, such as figure 1 shown, including:

[0051] Vibration excitation device for vibration excitation of aero-engine piping;

[0052] A pipeline clamping device for clamping the pipeline of an aero-engine and connecting it with a vibration excitation device;

[0053] A vibration test and analysis device for detecting and analyzing vibration signals of aero-engine pipelines during the vibration test;

[0054] Assembly position measurement device for measuring the position of aeroengine piping constraints.

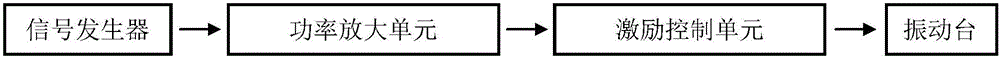

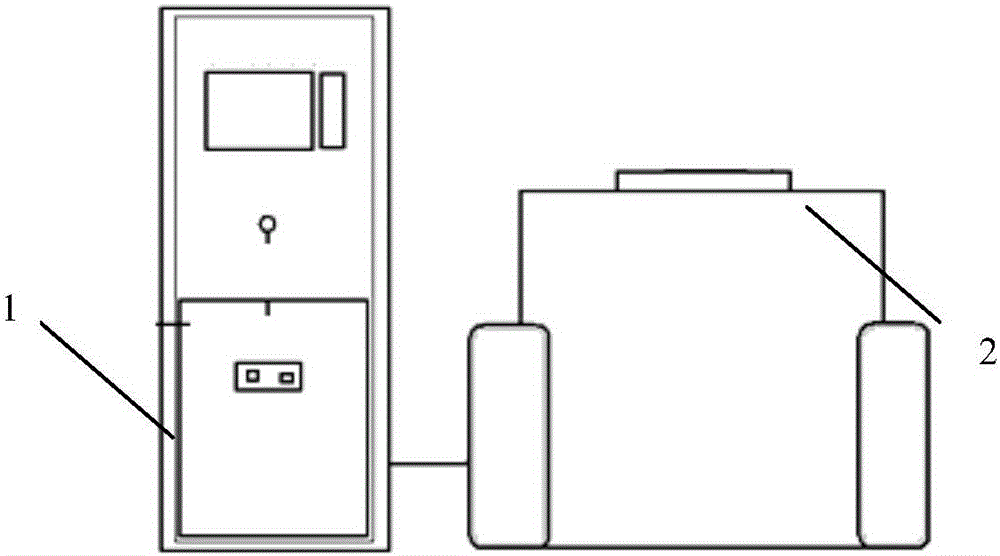

[0055] Such as figure 2 As shown, the vibration excitation device includes: a signal generator, a power amplification unit, an excitation control unit, and a vibration table; the output end of the signal generator is connected to the input end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com