Method for detecting proper installation or reversed installation of carrier cable base of railway overhead line on the basis of image

A load-bearing cable seat and detection method technology, which is applied in image enhancement, image analysis, image data processing, etc., can solve the problems of high-speed railway train safety hazards, cable-stayed cable slipping, and load-bearing cable seat detection openness, etc., to achieve detection speed Fast, less labor cost, high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The image-based method for detecting whether the load-bearing cable seat of a railway catenary is reversed or not is characterized in that the method steps are as follows:

[0046] Step 1: Input the original image of the cable seat and make it into a matching template after denoising;

[0047] Step 2: Take a test image of the cable seat;

[0048] Step 3: Select the captured cable seat detection image, compare and match with the matching template after denoising, to realize the rough positioning of the detection image;

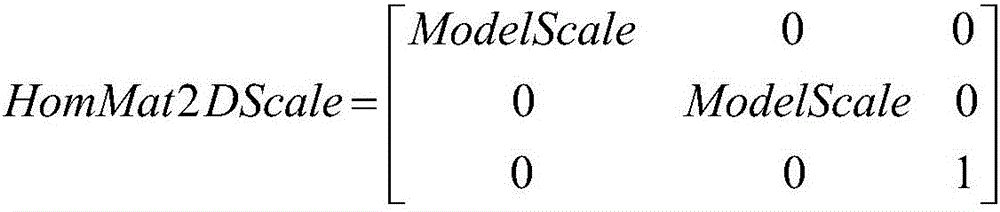

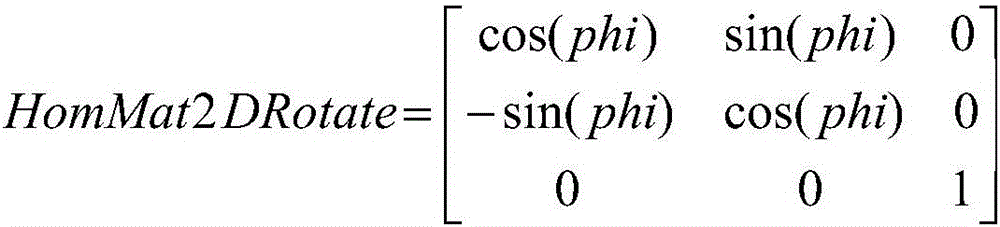

[0049] Step 4: For the successfully matched detection image in the third step, first perform the rotation and zoom processing, and then perform the normalization processing of the cable seat. After the processing is completed, crop the hook image of the cable seat;

[0050] Step 5: Detect the direction of the hook;

[0051] Step 6: Detect the direction of the diagonal cable connected to the hook;

[0052] Step 7: Determine whether the load-bearing cable seat is reve...

Embodiment 2

[0055] This embodiment is further improved on the basis of embodiment 1. The specific detection method of the hook direction in the step 5 is: perform gray-scale vertical projection of the hook image to obtain the gray value in the vertical direction of the image. The superimposed value of the vertical gray projection on the left of the hook image center is greater than the vertical gray projection superimposed value of the right, indicating that the opening direction of the hook is on the right; on the contrary, if the superimposed value of the vertical gray projection on the left of the center of the hook image If it is smaller than the vertical gray projection superimposition value on the right, it means that the opening direction of the hook is on the left.

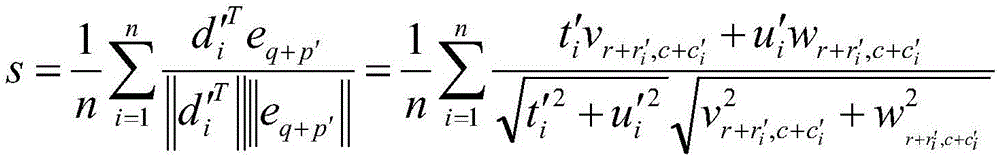

[0056] The specific detection method of the hook direction in the sixth step is to detect the edge of the hook image where the load-bearing seat is located by using a Gauss-based line segment detection method, extract the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com