Manufacturing method of mask structure

A manufacturing method and mask technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that the mask is easy to be stained with particles or impurities, affect the quality of the mask, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

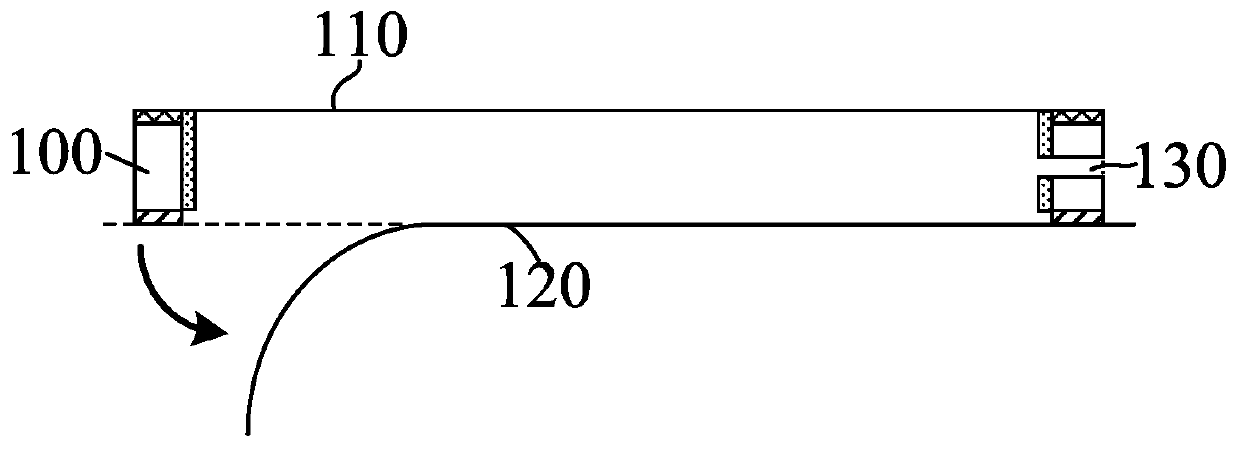

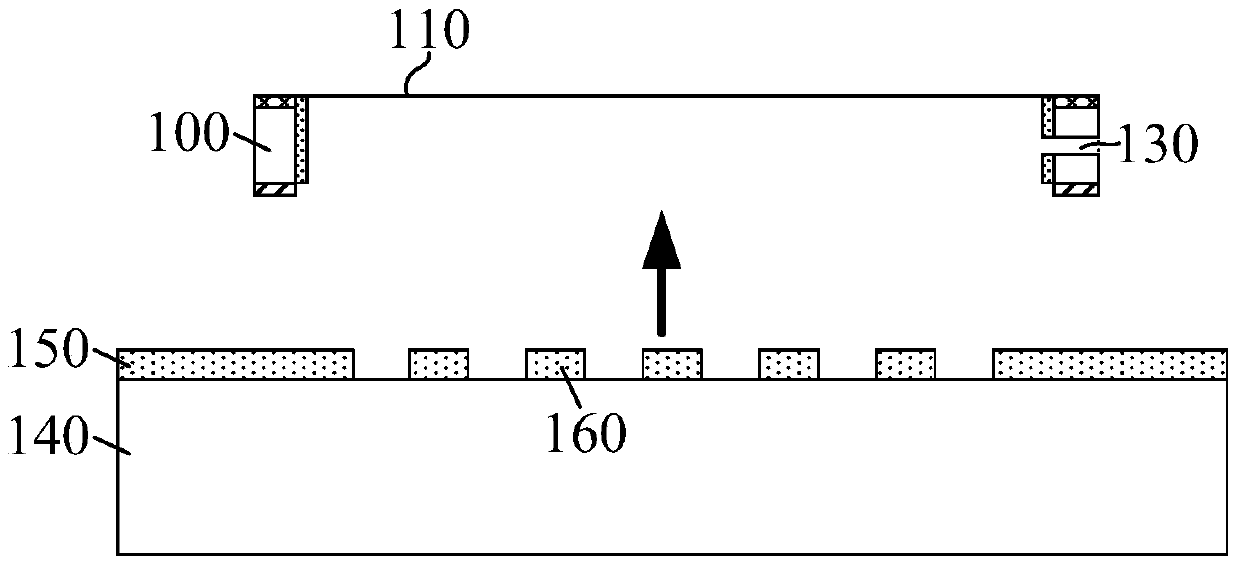

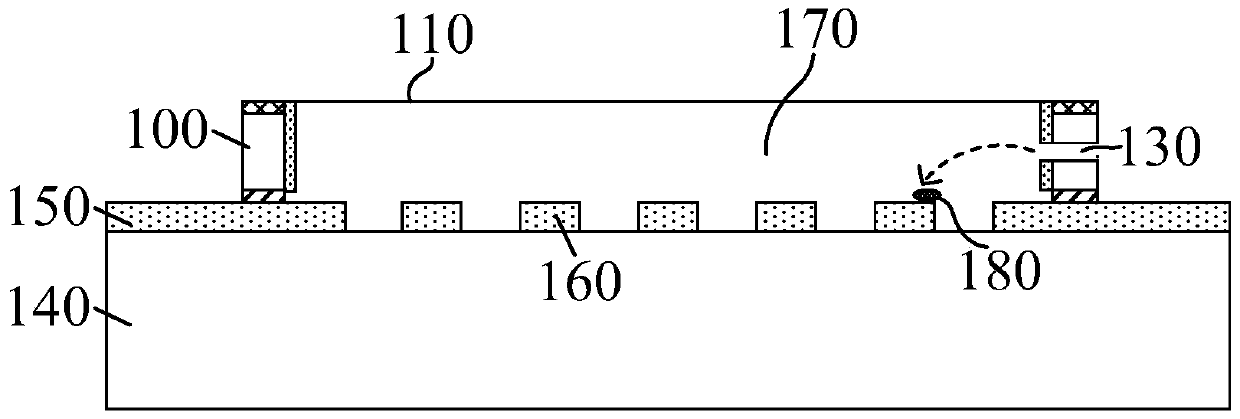

[0031] The mask plate manufactured by the prior art is easy to be stained with particles or impurities during use, combined with Figure 1 to Figure 3 Analyzing the reason why the mask is contaminated, in the mask manufacturing process, mainly includes: providing a mask and protective film device 100, the mask includes a substrate 140 and a patterned metal layer on the substrate 140; The protective film device 100 includes a protective film 110 at the top of the device, and a bracket positioned below the protective film 110. An opening 130 is formed in the side wall of one side of the bracket for separating the air pressure in the protective film device 100 from the outside world. The air pressure of the environment is the same; after the sealing tape 120 of the protective film is torn off, the substrate 140 is directly adhered to the protective film device 100, so that the patterned metal layer is in contact with the bracket to form a protective film 110. The mask plate, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com