Patents

Literature

31 results about "Charged impurity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous membranes containing exchange resins

InactiveUS20090039019A1Fast dynamicsLower overall pressure dropMembranesSemi-permeable membranesPorous membraneCharged impurity

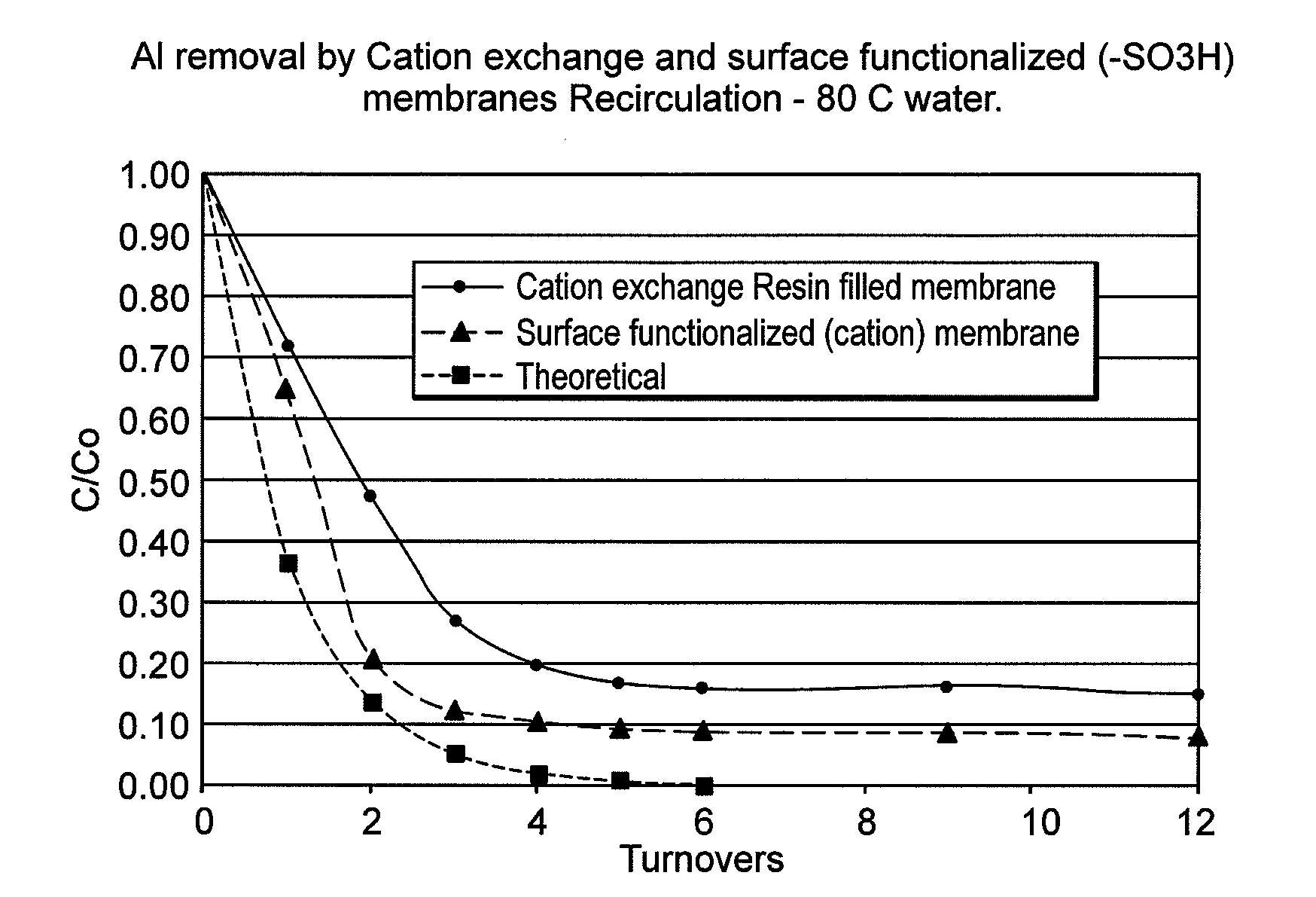

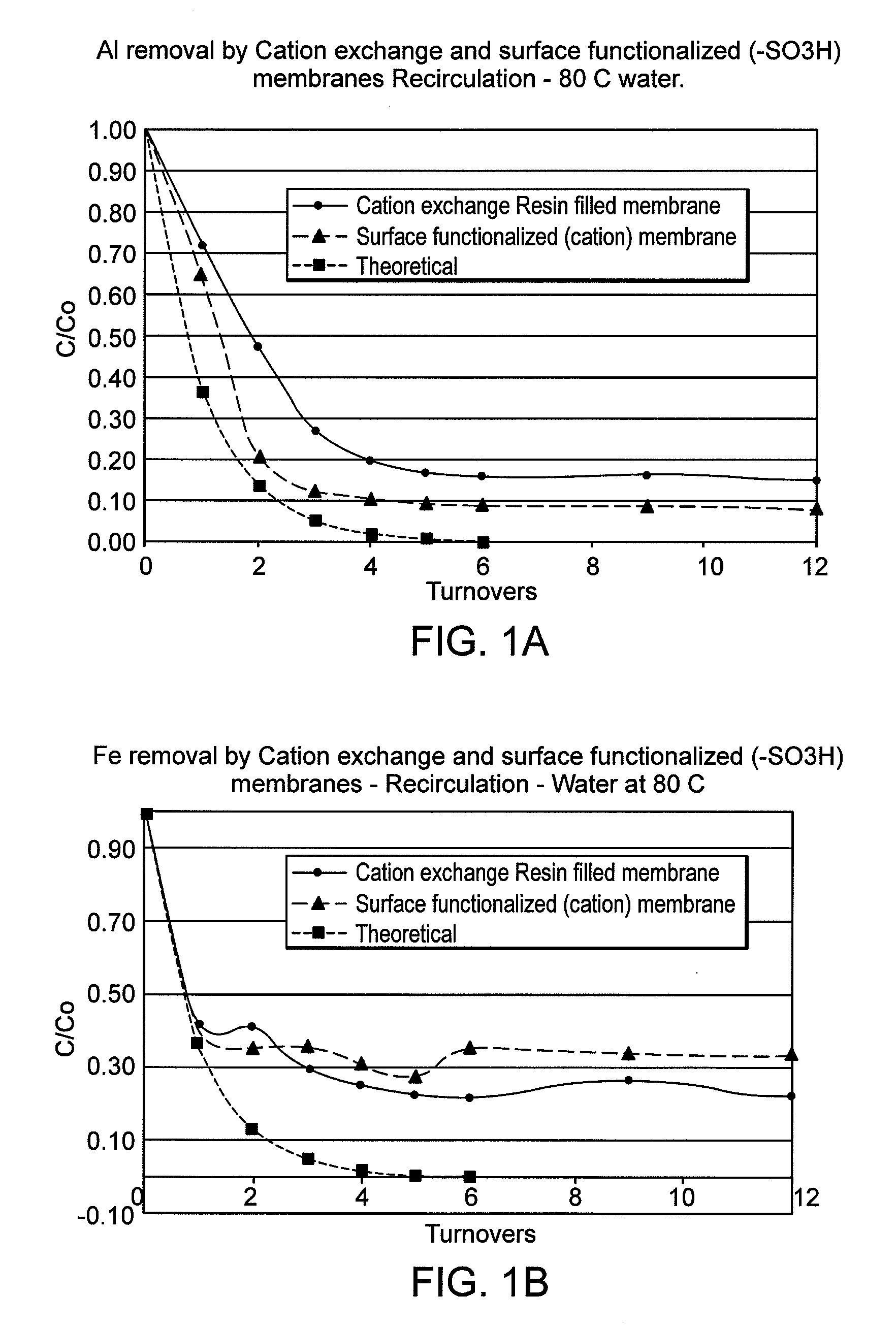

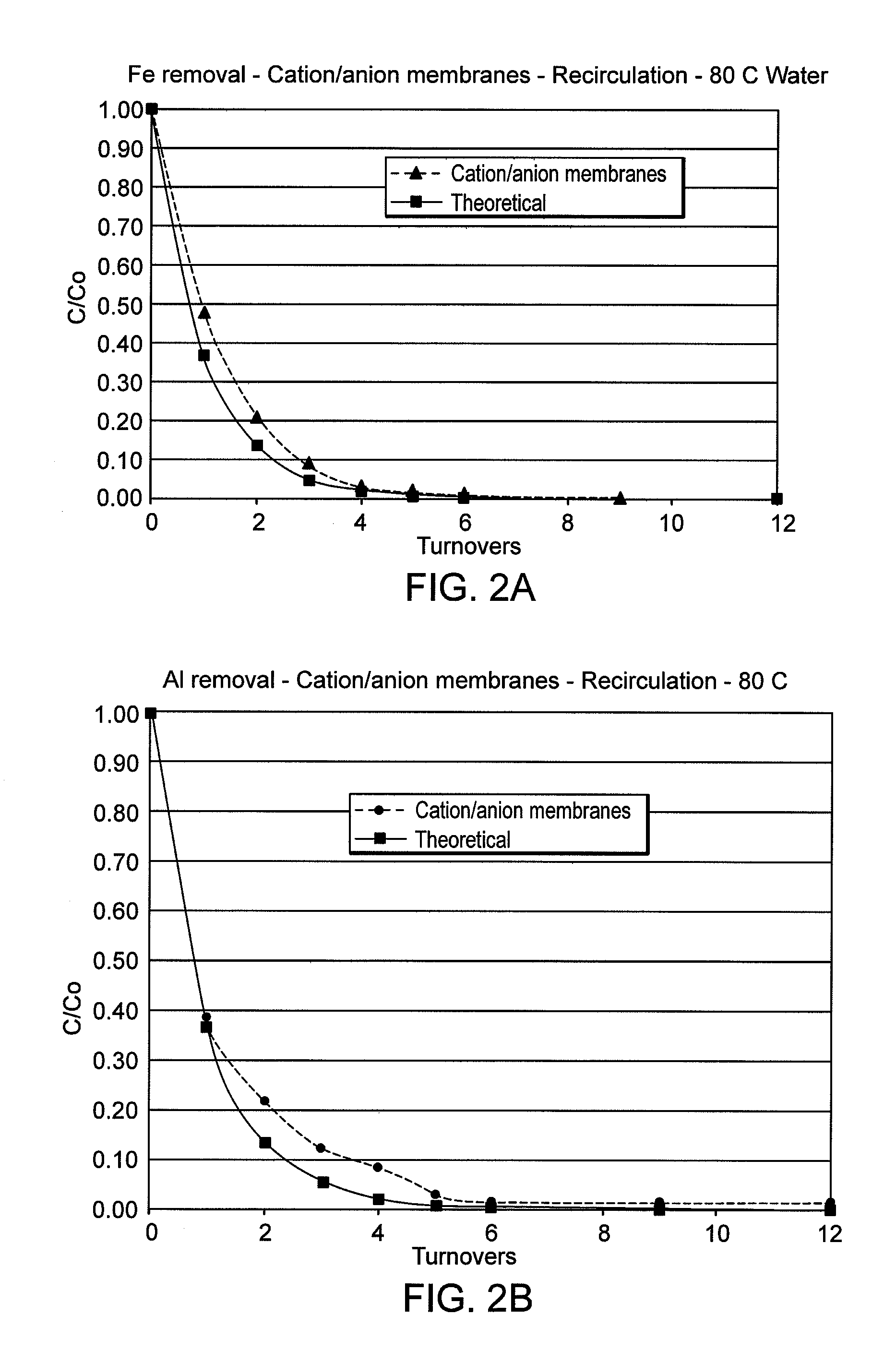

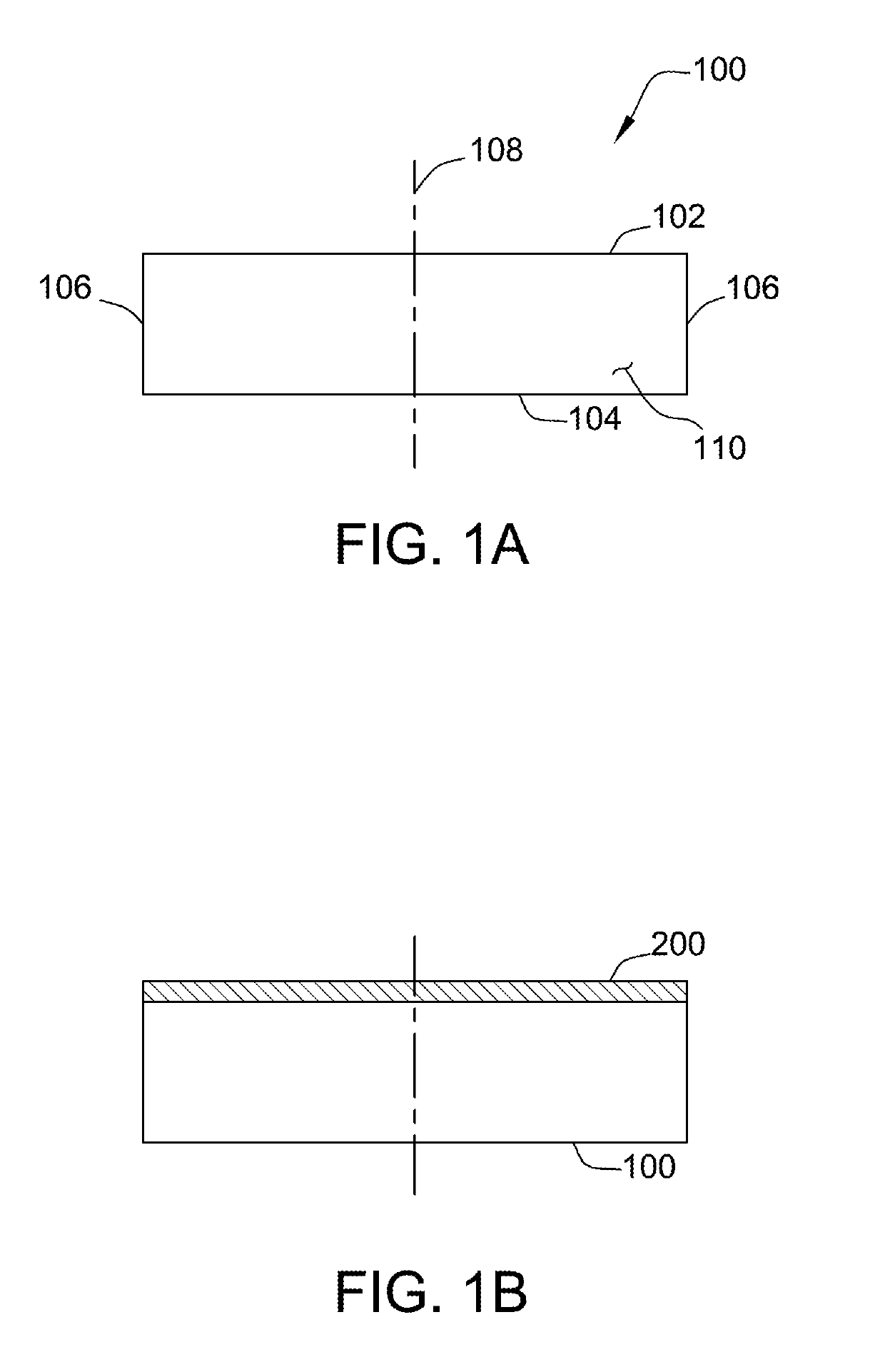

Articles that include two or more exchange resins in one or more microporous membranes, where the membranes remove oppositely charged impurities from a fluid in contact with the membranes, are disclosed. Methods for using such devices to remove charged impurities from fluid in contact with the membrane are provided.

Owner:ENTEGRIS INC

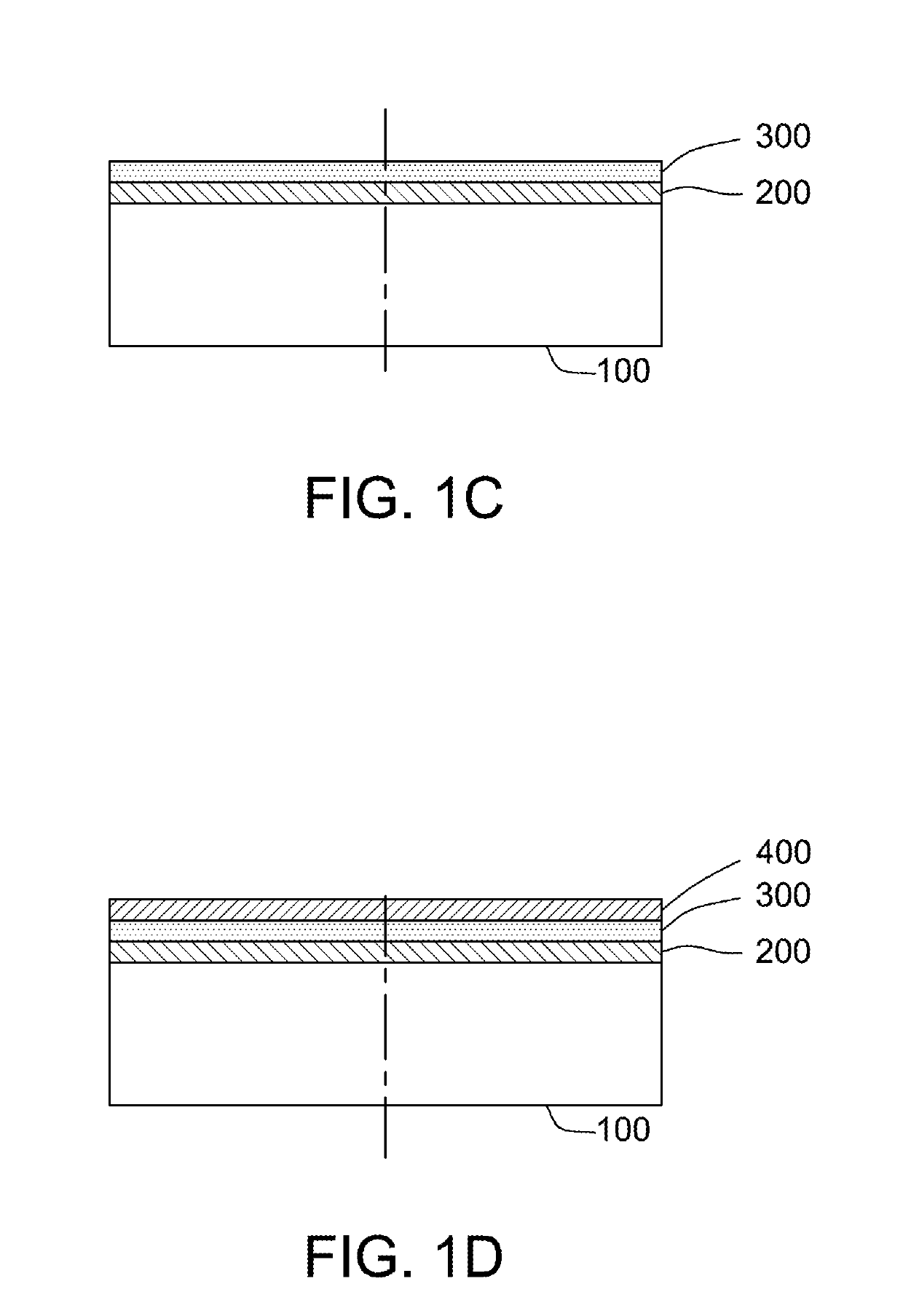

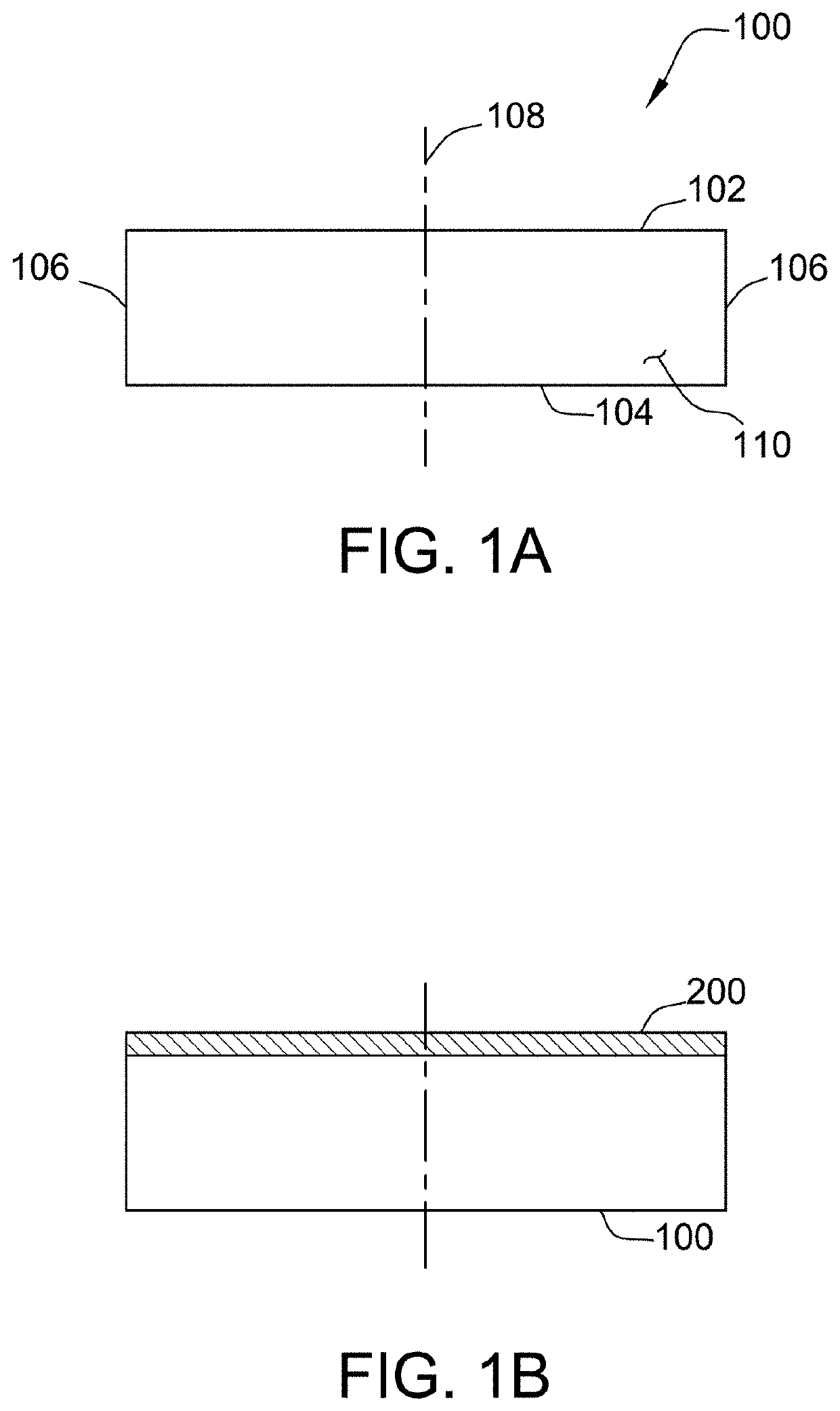

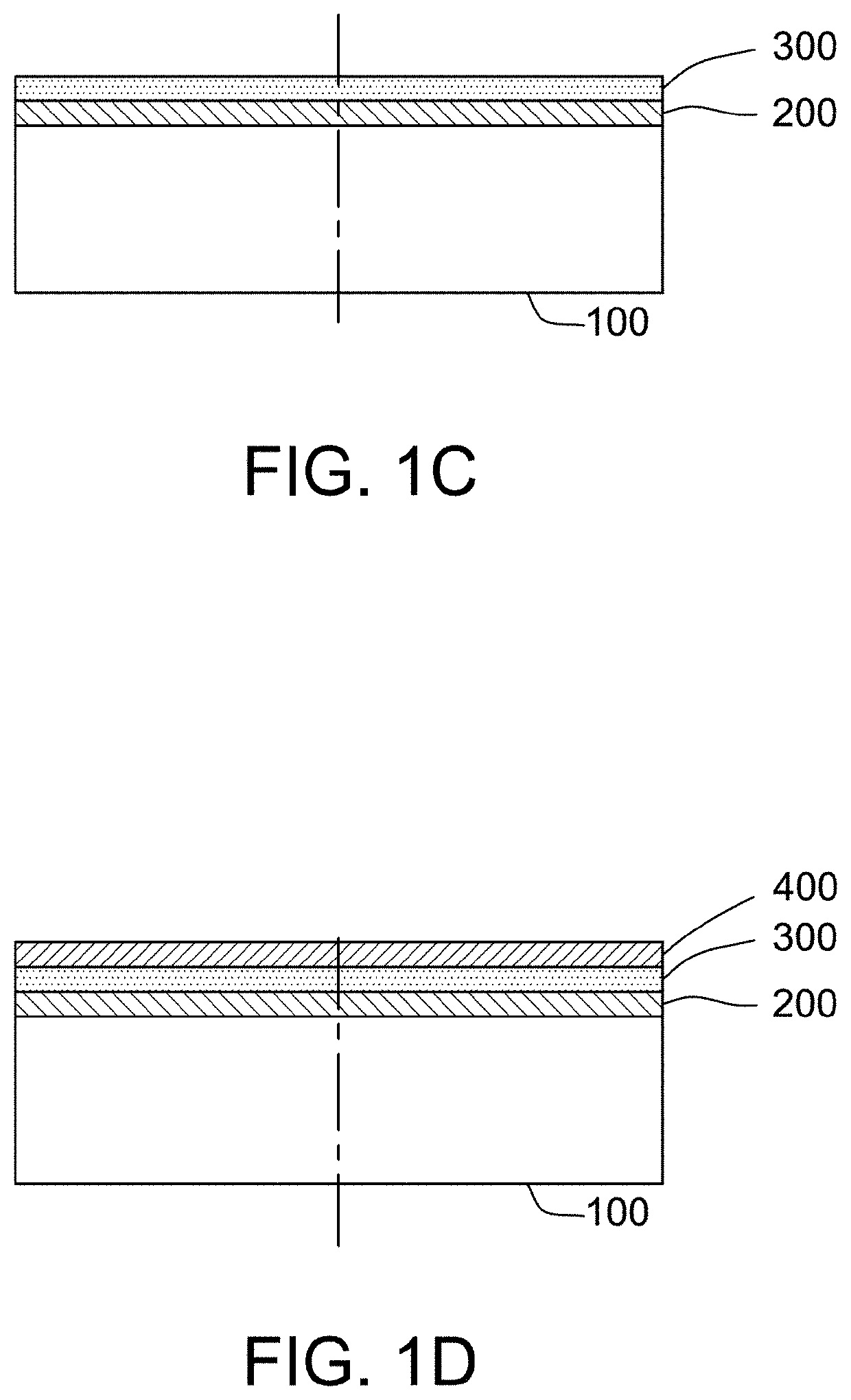

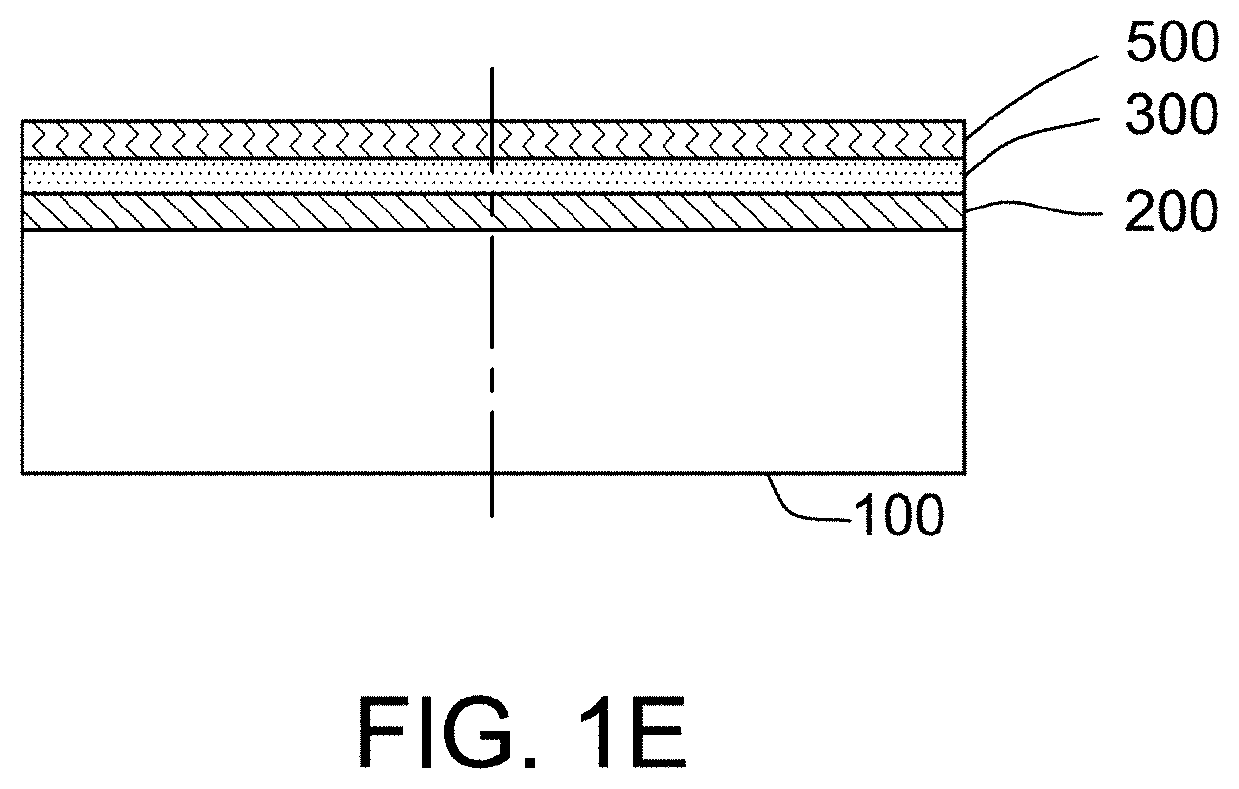

Direct formation of hexagonal boron nitride on silicon based dielectrics

A scalable process for fabricating graphene / hexagonal boron nitride (h-BN) heterostructures is disclosed herein. The process includes (BN)XHy-radical interfacing with active sites on silicon nitride coated silicon (Si3N4 / Si) surfaces for nucleation and growth of large-area, uniform and ultrathin h-BN directly on Si3N4 / Si substrates (B / N atomic ratio=1:1.11±0.09). Further, monolayer graphene van der Waals bonded with the produced h-BN surface benefits from h-BN's reduced roughness (3.4 times) in comparison to Si3N4 / Si. Because the reduced surface roughness leads to reduction in surface roughness scattering and charge impurity scattering, therefore an enhanced intrinsic charge carrier mobility (3 folds) for graphene on h-BN / Si3N4 / Si is found.

Owner:GLOBALWAFERS CO LTD +1

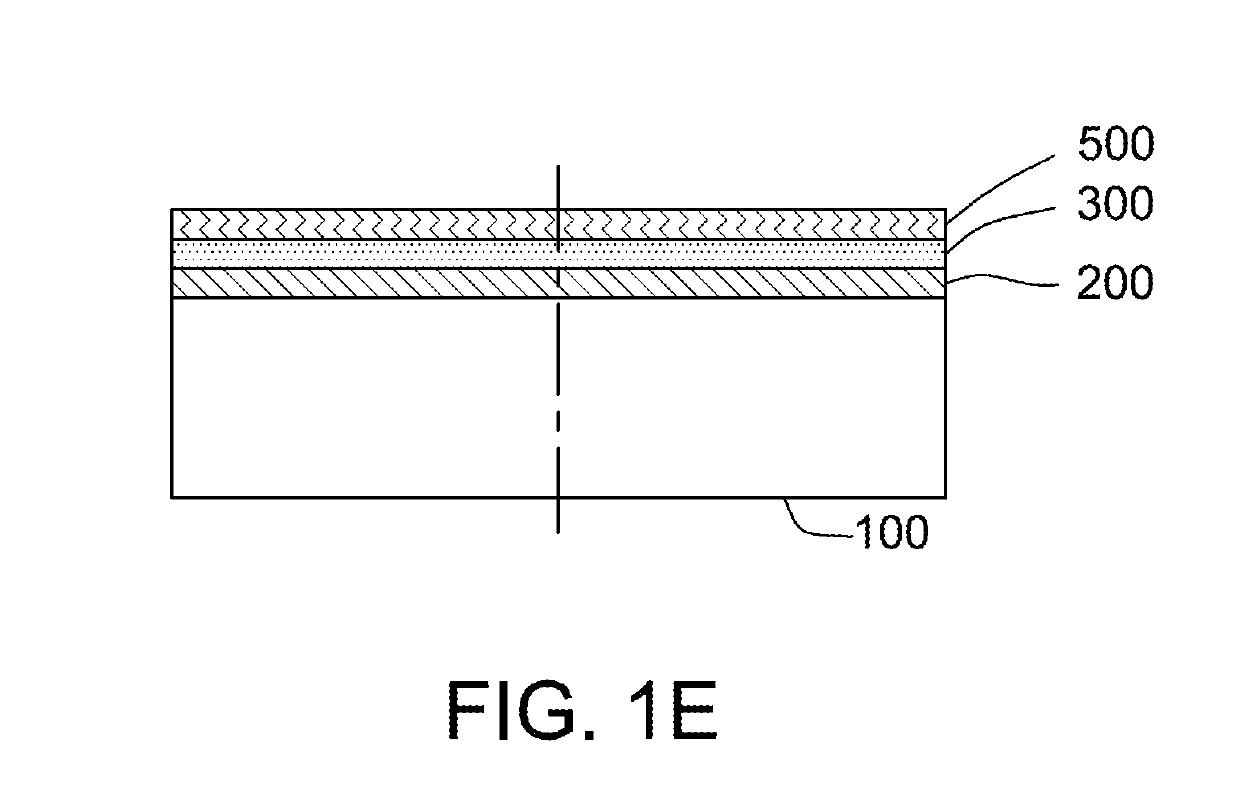

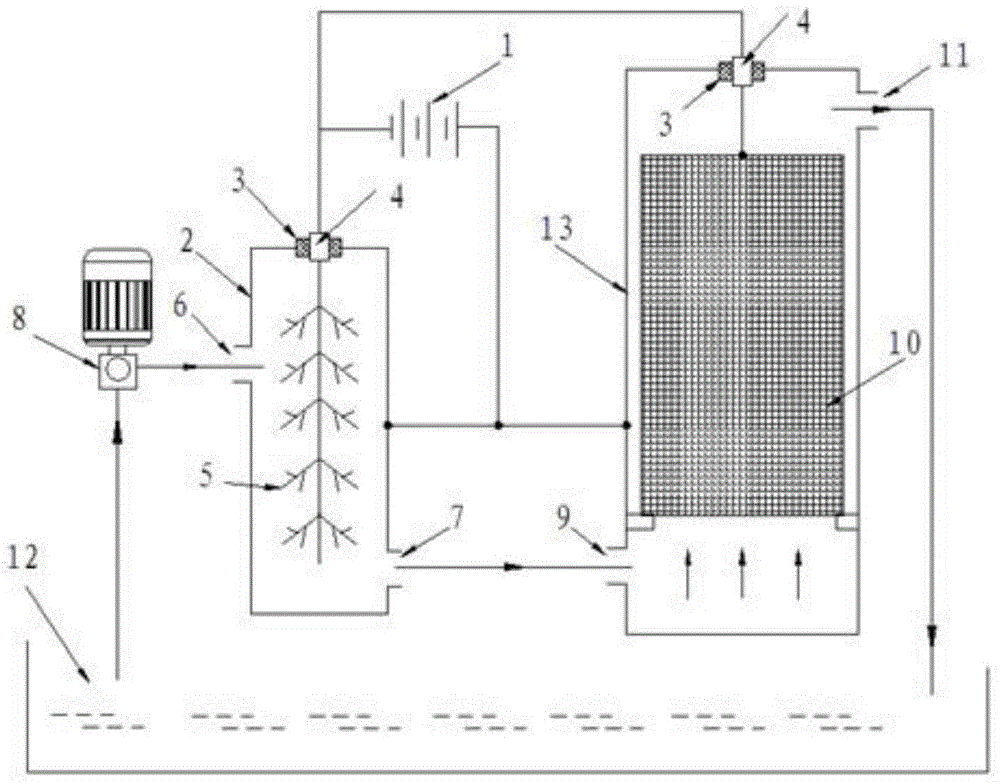

Air purifier and method of purifying air

InactiveCN109070096AAutomated maintenanceAutomated CleanabilityMechanical apparatusLighting and heating apparatusAir purifiersIonization chamber

According to an example aspect of the present invention, there is provided an air purifier comprising: an ionization chamber arranged for charging impurity particles in the incoming air;electrostaticcollector plates located after the ionization chamber and arranged for trapping the charged impurity particles. The air purifier further comprises a washing system above the electrostatic collector plates, which washing system is arranged for dispensing a cleansing solution onto the electrostatic collector plates;a fan system capable of two-mode action: a purification mode of aspirating air to bepurified upwards,into the ionization chamber and subsequently through the electrostatic collector plates, and a drying mode of blowing air in the opposite direction.

Owner:AAVI TECH

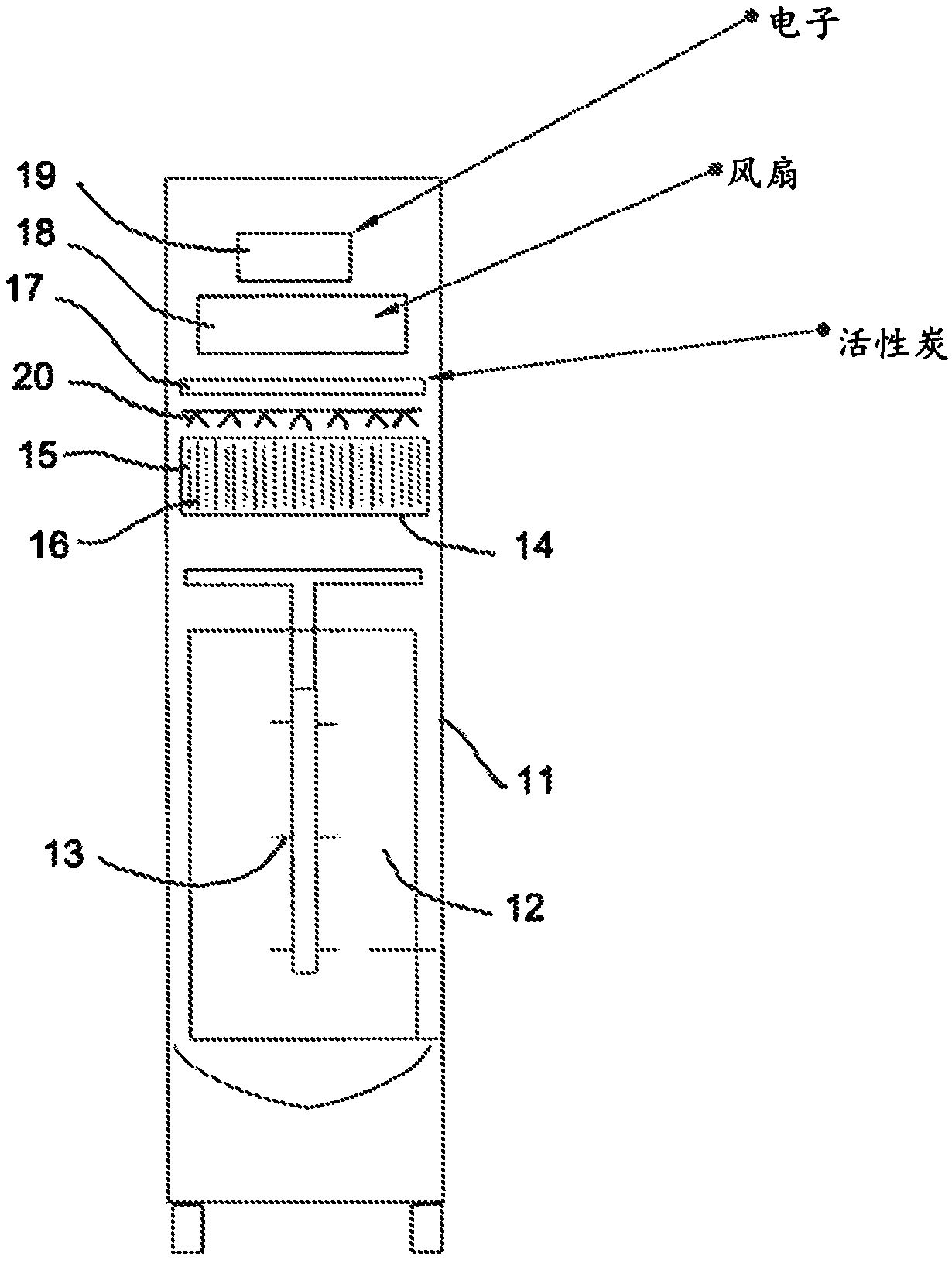

Novel electrostatic oil filtration device for lubrication oil

InactiveCN103977901AImprove cleanlinessSimple structureElectrostatic separatorsFiltrationCharged impurity

The invention discloses an electrostatic oil filtration device for lubrication oil. The electrostatic oil filtration device for the lubrication oil comprises an electrostatic filtration body, wherein a charging device is connected with the front part of the electrostatic filtration body and used for charging impurities in the lubrication oil. By virtue of the electrostatic oil filtration device for the lubrication oil, firstly, a barb type charging device is used for charging the impurities in the lubrication oil; subsequently, an electrostatic oil absorption and filtration device is used for filtering the impurities in the lubrication oil; the electrostatic filtration body can be made in a flat electrode type structure, a cylinder electrode type structure or other electrostatic field structures. Since the method is proper, the electrostatic oil filtration device is simple and practical in structure, so that a product has the quite obvious popularization advantage. By virtue of the electrostatic oil filtration device, the efficiency for filtering the impurities in the lubrication oil is exponentially improved; the cleanliness of filtered lubrication oil is also significantly increased.

Owner:周建伟

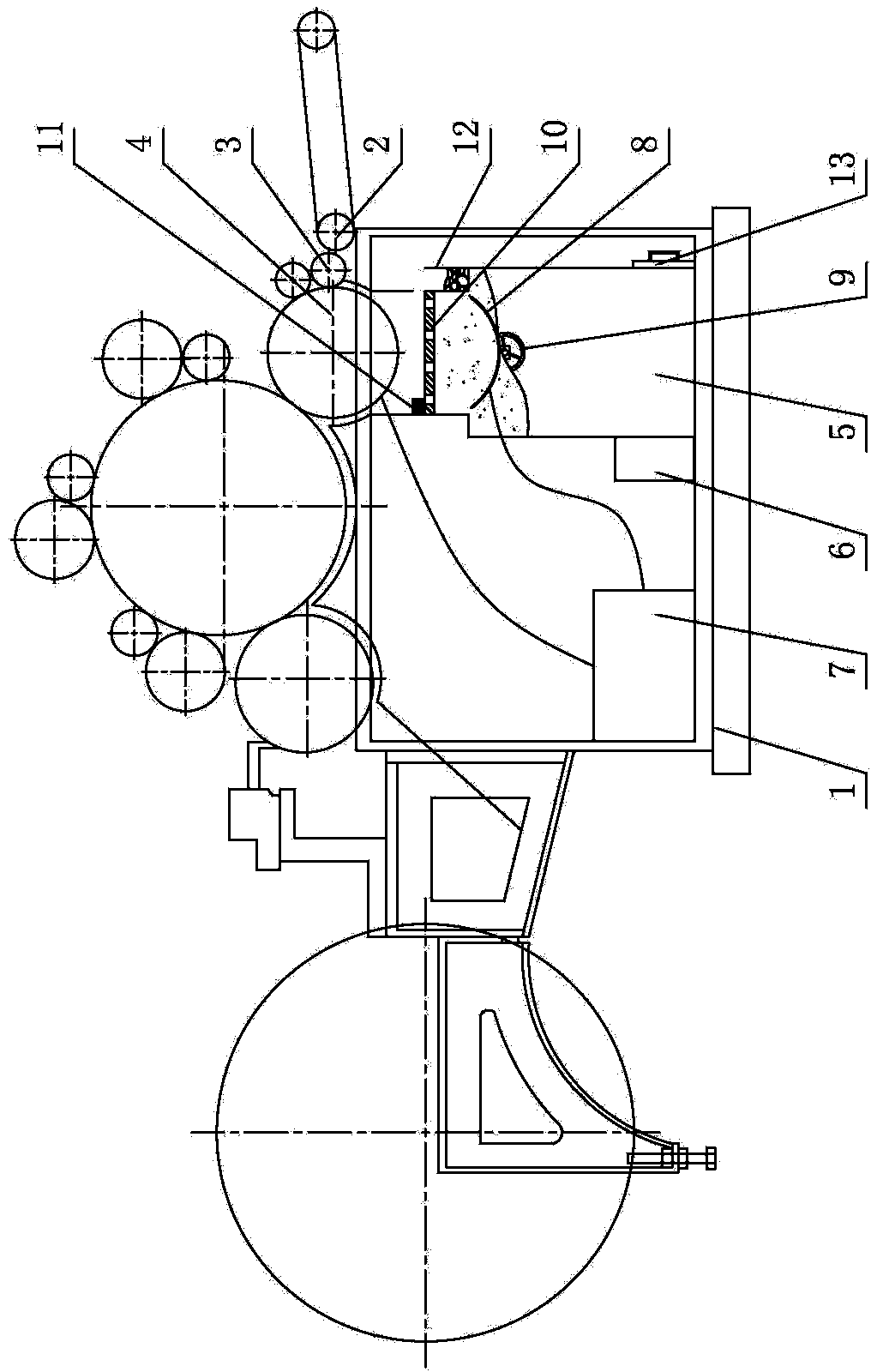

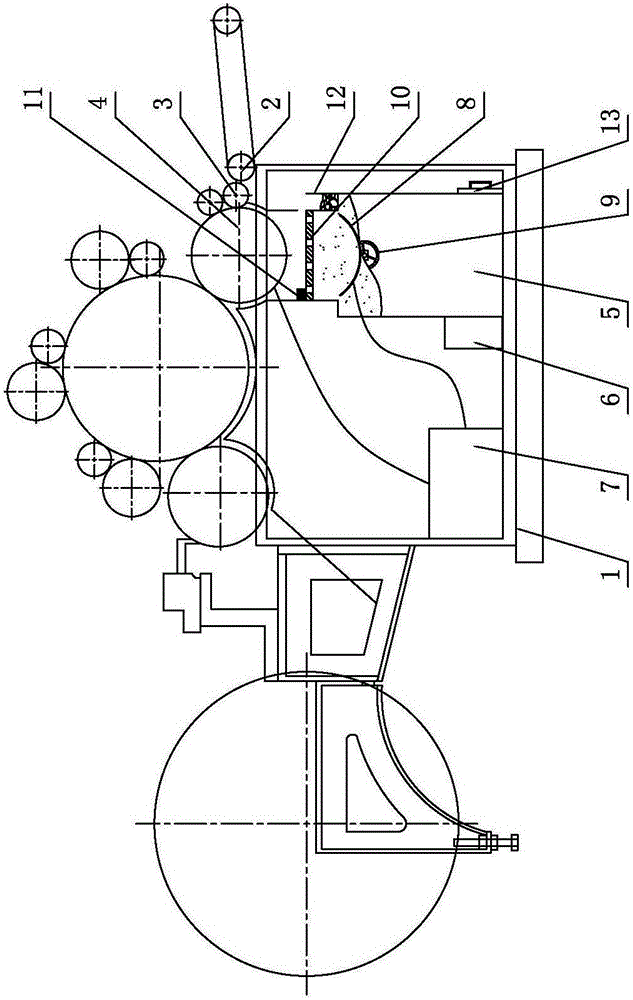

Dust-removing cotton fluffer

ActiveCN104294415AImprove cleanlinessSolve technical problems that cannot be effectively removedLap forming devicesTextile disintegration and recoveryWind drivenCotton fibre

The invention discloses a dust-removing cotton fluffer. The dust-removing cotton fluffer comprises a frame, a feeding rack, a cotton feeding roller and a licker-in arranged correspondingly to the cotton feeding roller, wherein the feeding rack is arranged in front of the frame; the cotton feeding roller is arranged on the tail end of the feeding rack; a dust collection chamber is arranged under the licker-in and a fan for collecting dust is connected to the dust collection chamber. The cotton fluffer further comprises a high-voltage power source, wherein one electrode of the high-voltage power source is electrically connected with the external surface of the licker-in, while the other electrode of the high-voltage power source is electrically connected with a dust collection plate arranged in the dust collection chamber; the dust collection plate is directly arranged under the licker-in. the dust-removing cotton fluffer has the advantages that the electric-field dust removal technique is adopted on the basis of existing wind-driven dust removal so that impurities such as dust to have charges opposite to the charges of the dust collection plate in the cotton fiber release process of the licker-in, next, the charged impurities such as dust are adsorbed on the dust collection plate under the action of the electric field between the licker-in and the dust collection plate, and most dust can be removed in combination with the action of a fan, and therefore, the technical problem that the impurities cannot be removed effectively due to the electrostatic interaction is effectively solved and the cleanness of the cotton fibers is remarkably improved.

Owner:盐城美逸家纺有限公司

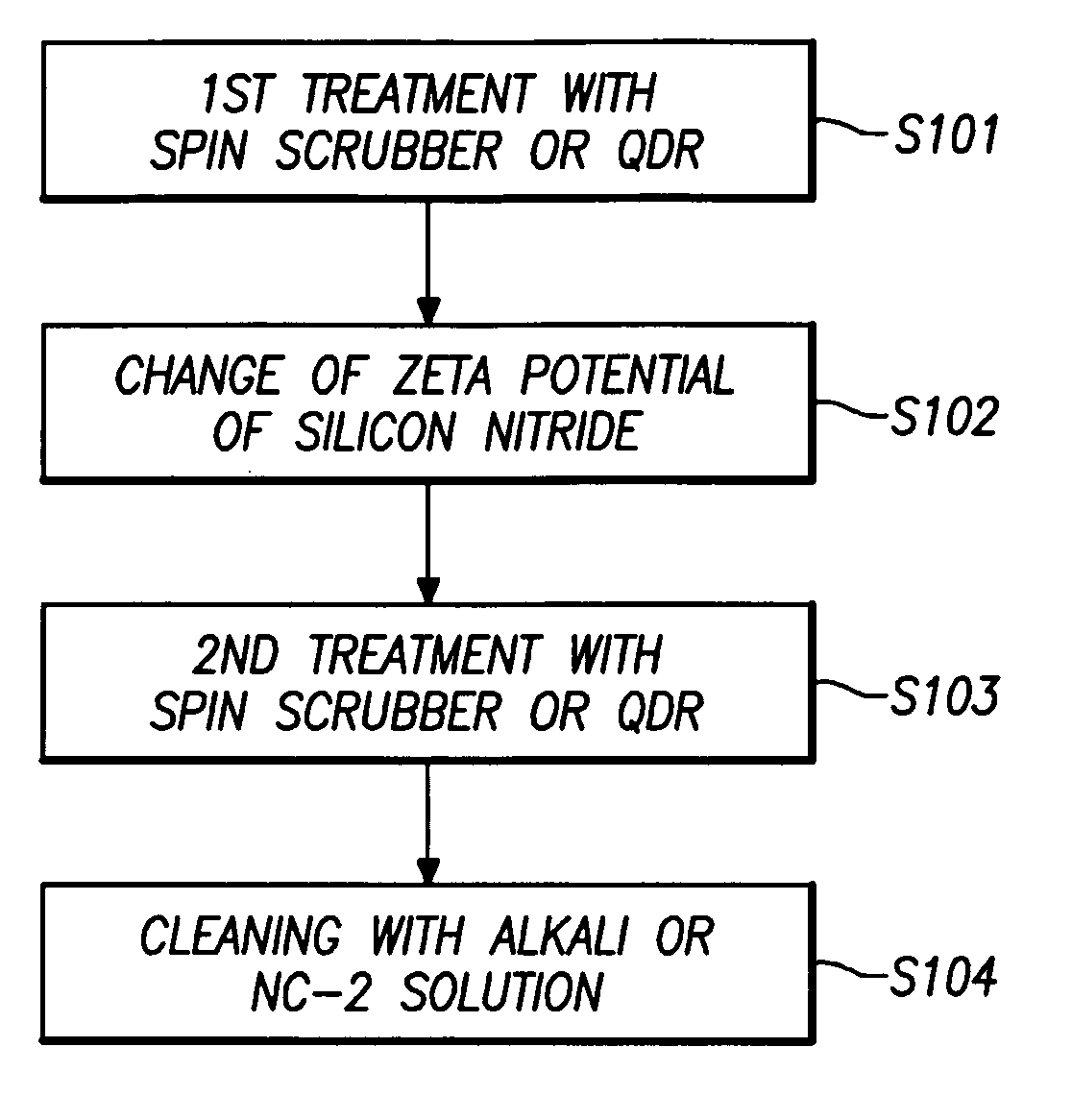

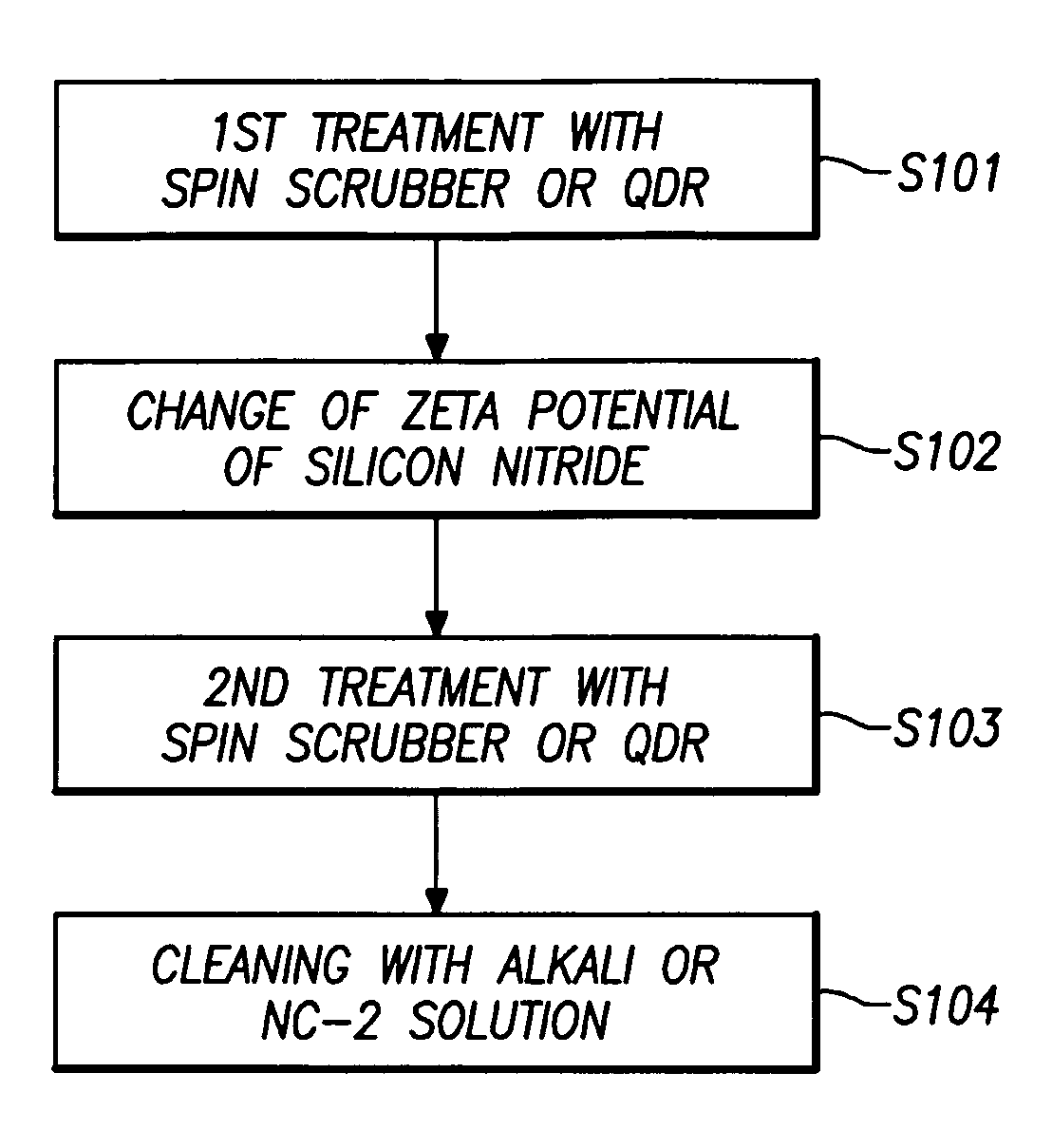

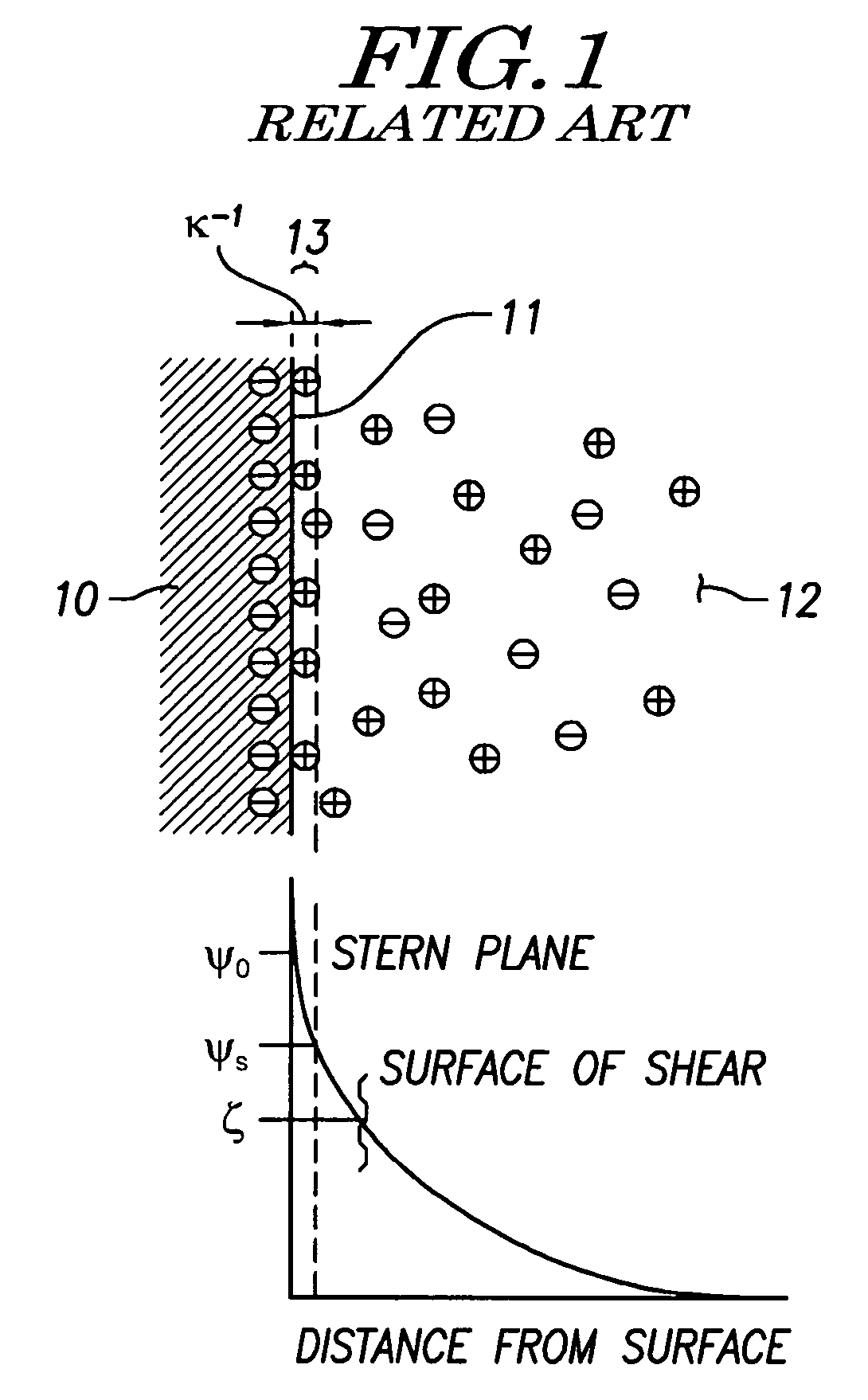

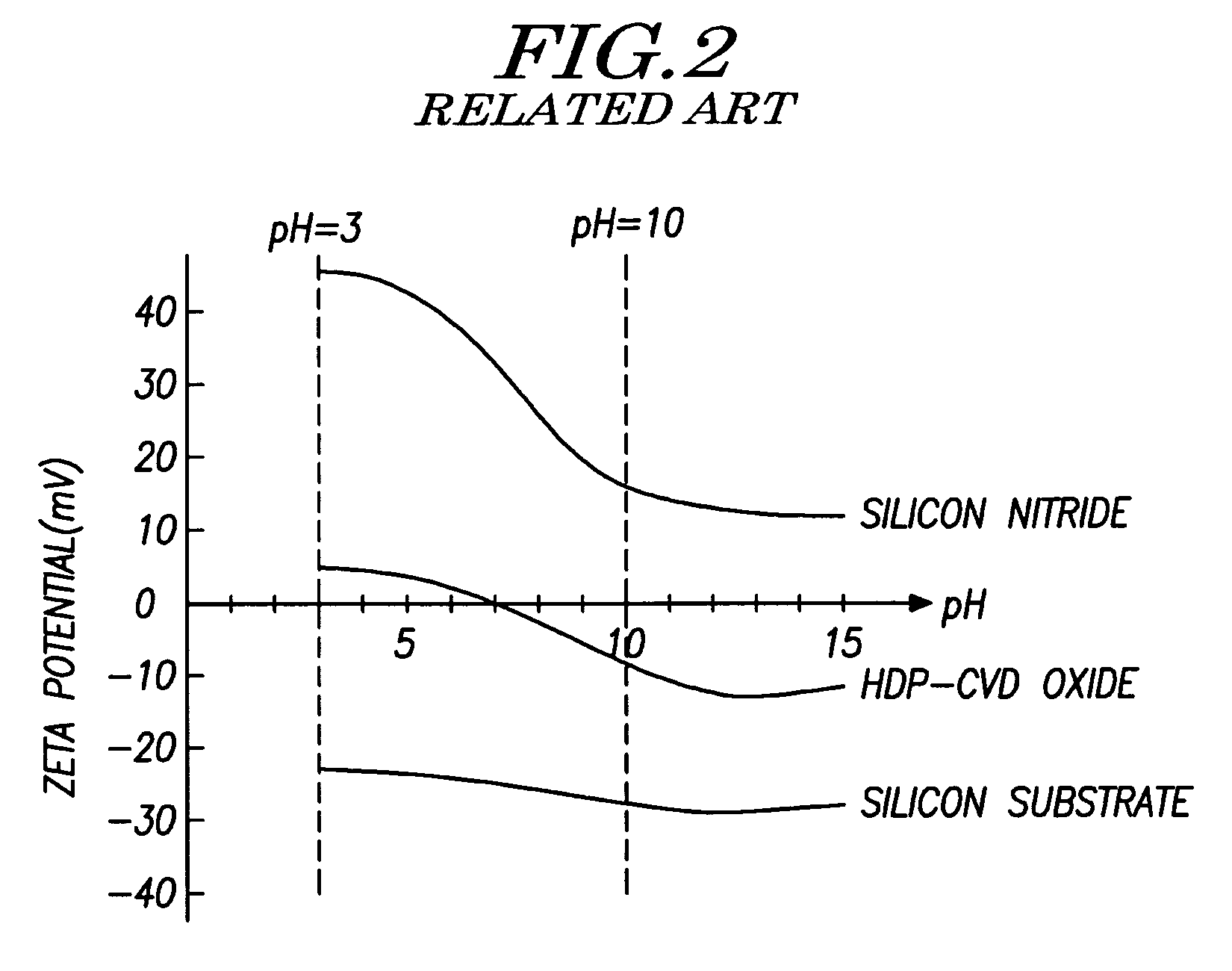

Method of cleaning silicon nitride layer

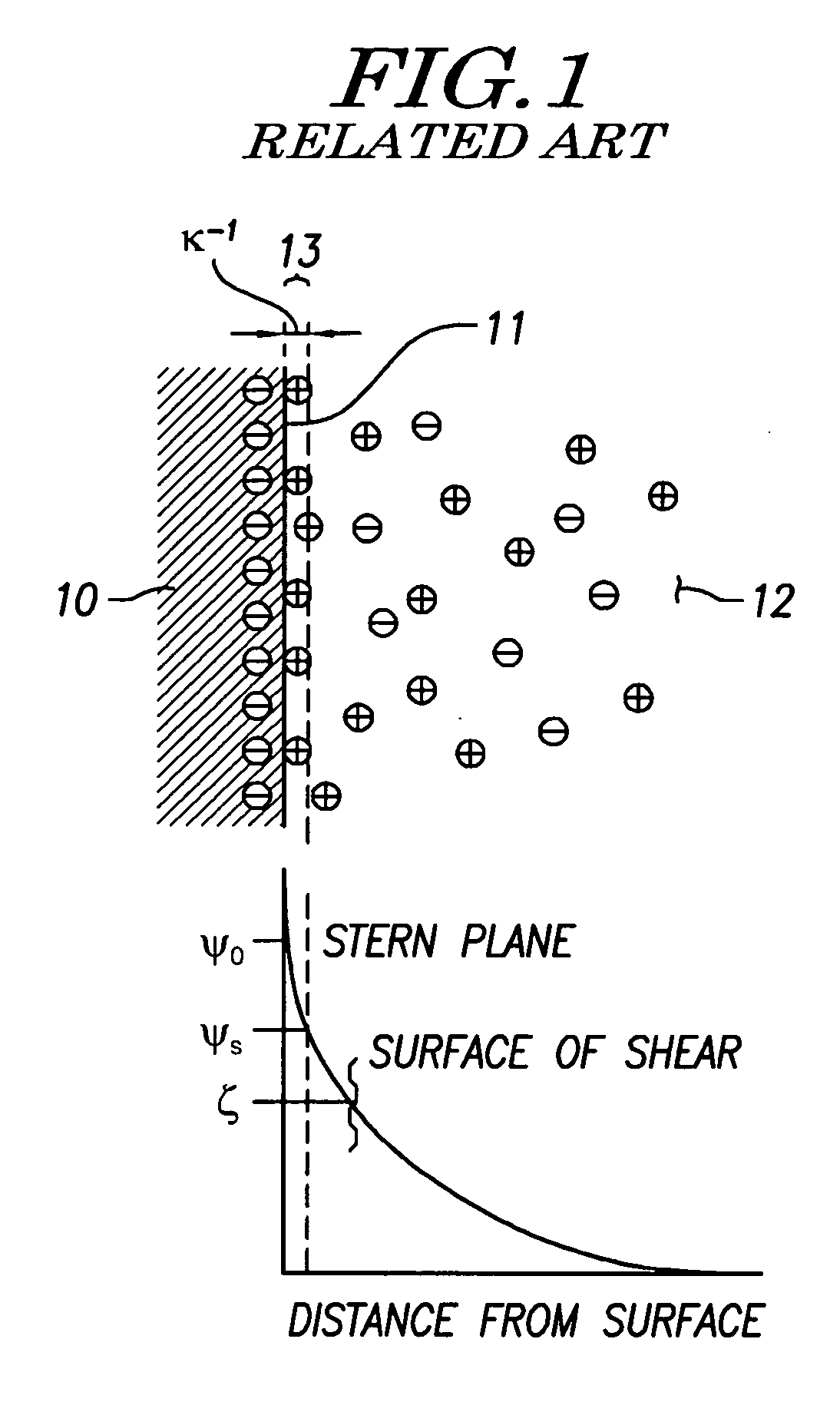

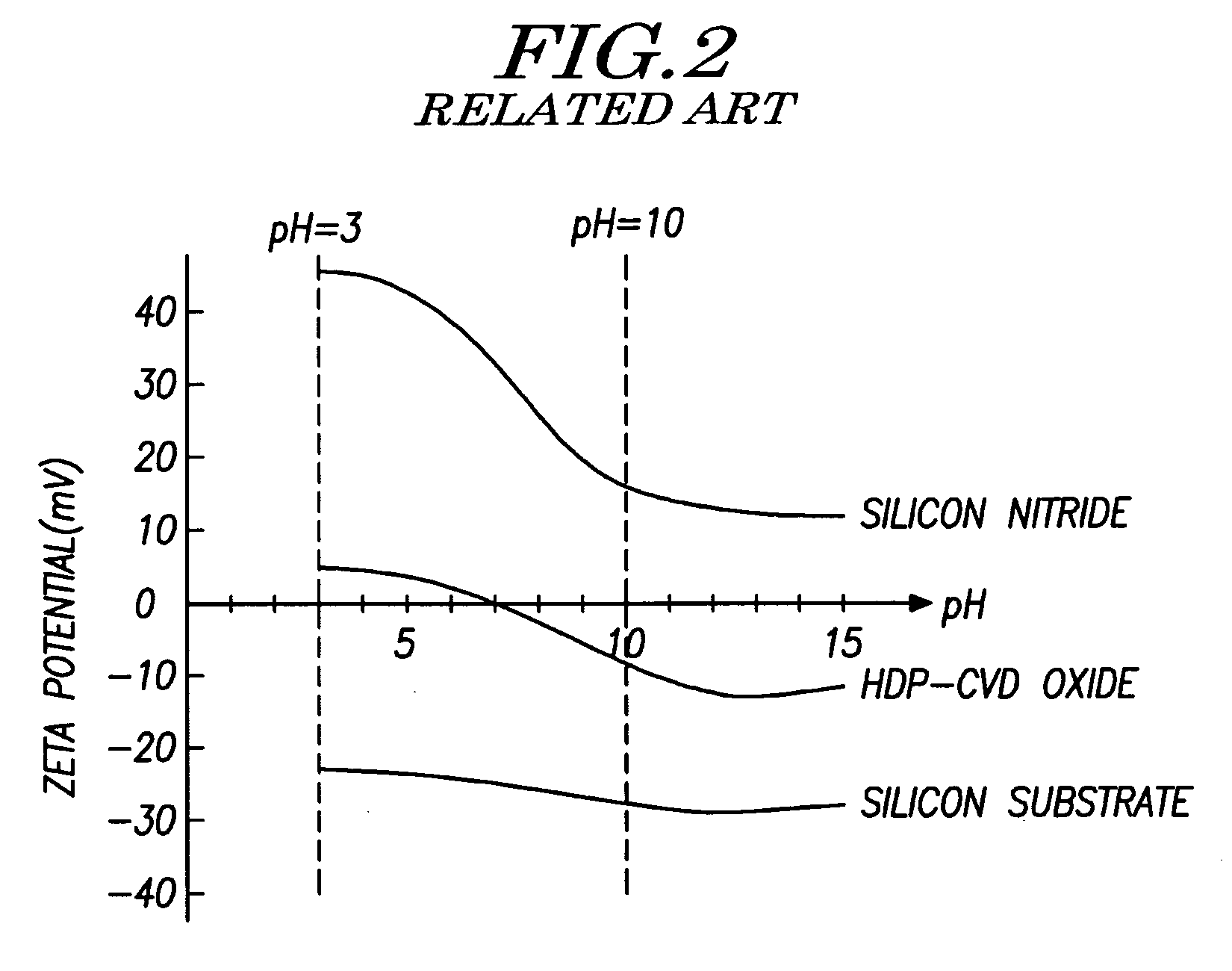

InactiveUS20060141803A1Efficient removalSemiconductor/solid-state device manufacturingSemiconductor devicesZeta potentialOptoelectronics

A method of cleaning a silicon nitride layer on a substrate is provided to effectively remove negative-charged impurities such as polymer and particle from the silicon nitride layer. In the method, the zeta potential of the silicon nitride layer is changed from positive to negative, and then the silicon nitride layer is cleaned with a first solution selected from an alkali solution and an NC-2 solution. So the negatively-charged impurities can be easily removed due to a repulsion force. The substrate can be treated with spin scrubber or quick dump rinse before and / or after the changing of the zeta potential. To change the zeta potential, the substrate can be dipped into a second solution such as an SC-1 solution, an NC-2 solution, and an alkali solution.

Owner:DONGBU ELECTRONICS CO LTD

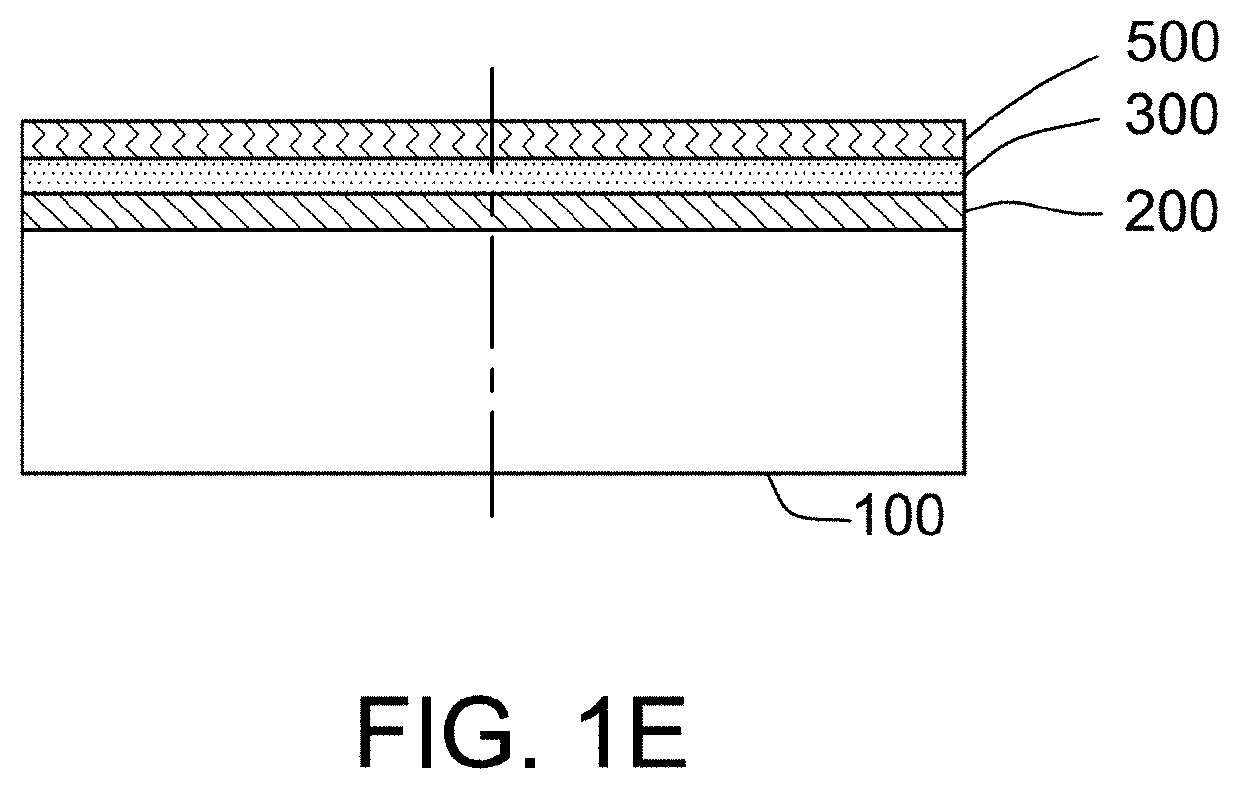

Manufacturing method of mask structure

ActiveCN106486345AQuality improvementSemiconductor/solid-state device manufacturingEngineeringCharged impurity

The invention provides a manufacturing method of a mask structure. The manufacturing method comprises the steps of: providing a mask plate which comprises a substrate and a pattern metal layer arranged on the substrate; providing a protective film device which comprises a bracket and a protective film adhered to the top part of the bracket, wherein the bracket comprises a plurality of supporting side walls, the plurality of supporting side walls are connected with one another to form a closed structure, and an opening is formed in one supporting side wall; placing the protective film device in an electrostatic field, and blowing a charged gas into the opening; and moving the protective film device away from the electrostatic field, and adhering the pattern metal layer on the bottom part of the bracket. Before adhering the bracket with the pattern metal layer, the gas is blown into the opening so that impurities at the opening are blown off; and the protective film device is placed in the electrostatic field generated by an electrostatic generation device, and the blown-off and charged impurities are absorbed and away from the protective film device under the action of the electrostatic field, thus the impurities at the opening are removed, and the quality of the mask plate is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Superconductivity based on bose-einstein condensation of electron or electron-hole pairs in semiconductors

ActiveUS20110129945A1Alleged superconductivity devicesSemiconductor/solid-state device manufacturingBinding energyElectron hole

The invention describes a method of achieving superconductivity in Group IV semiconductors via the addition of doubly charged impurity atoms to the crystal lattice. The doubly charged impurities function as composite bosons in the semiconductor. Increasing the density of the composite bosons to a level where their wavefunctions overlap, results in the formation of a Bose condensate. The concentration of the doubly charged impurity atoms in the host lattice and the binding energy of the impurities are important factors in determining whether a Bose condensate will form. Doubly charged impurities must be present in the semiconductor at a concentration at which they exhibit overlapping wavefunctions, but still exist within the crystal lattice as bosons.

Owner:WISE WILLIAM G

Extraction, separation and purification process of brasenia schreberi polysaccharide

ActiveCN106146685AOvercome the disadvantage of low extraction rateThere is no safety problem in the use of strong alkaliBulk chemical productionAlkaline proteaseLow ionic strength

The invention discloses an extraction, separation and purification process of brasenia schreberi polysaccharide. According to the process, the supercritical CO2 extraction technology is utilized, the defect that the extraction rate is low through a hot water extraction method and a NaOH extraction method is overcome, and the safety problem appearing in the situation that strong base needs to be used in NaOH extraction does not exist. When a crude product of the brasenia schreberi polysaccharide is purified, alkaline protease is adopted for treating and removing protein; cetyl trimethyl ammonium bromide and the brasenia schreberi polysaccharide can form quaternary amine complexes, the complexes do not dissolve in an aqueous solution with a low ionic strength and can dissociate and dissolve when the ionic strength is high, and the separation and purification effect is better; by using 312 weak-acid anionic exchange resin chromatography, some positively-charged impurities can be removed, and the separation and purification effect is better.

Owner:CHONGQING THREE GORGES MEDICAL COLLEGE

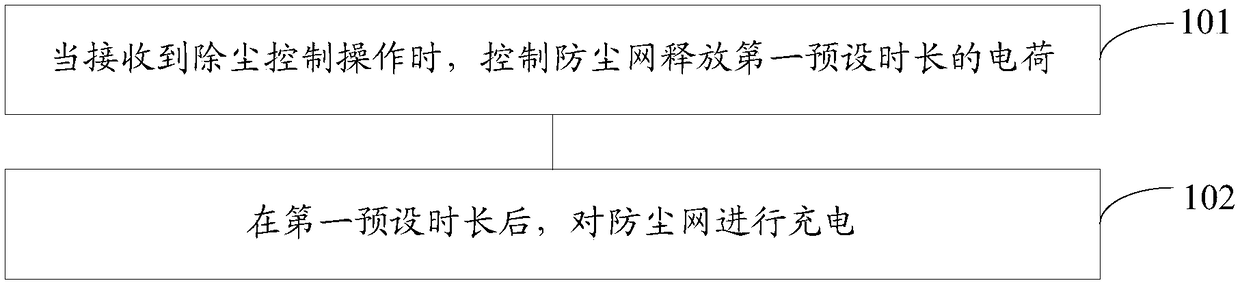

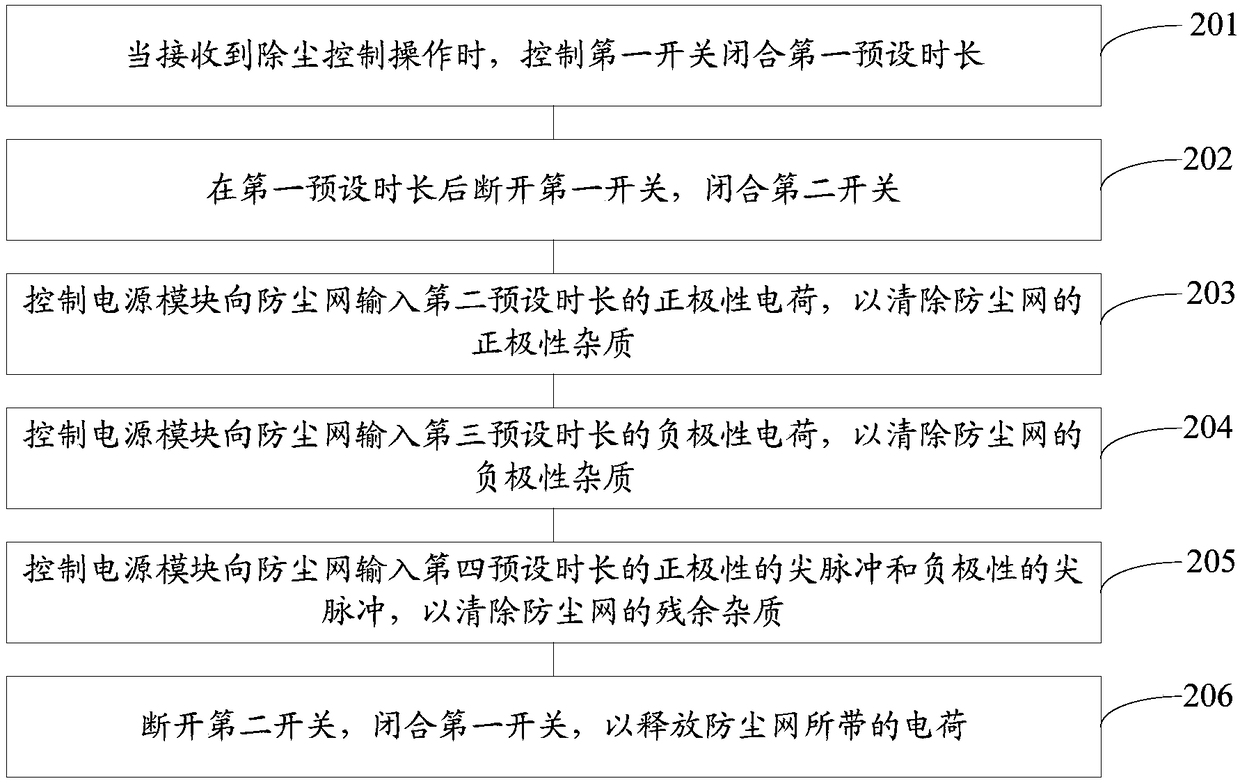

Dust removing method and mobile terminal

The embodiment of the invention provides a dust removing method and a mobile terminal. The dust removing method comprises the steps of controlling a dust screen to release charges for a first preset time when receiving a dust removing control operation, and charging the dust screen after the preset time. Dust removing is performed on the dust screen both in the charge releasing and charging process for the dust screen. Firstly, the dust screen is controlled to release charges, thereby being capable of eliminating the electric property of part of the dust, and thus cleaning part of the dust; secondly, a charging operation is performed on the dust screen, thereby cleaning charged impurities in the dust screen; and finally the dust removing for the dust screen is completed. The dust removingscheme provided by the embodiment of the invention can automatically clean the dust of the dust screen without disassembling the whole machine, thereby facilitating users to use.

Owner:VIVO MOBILE COMM CO LTD

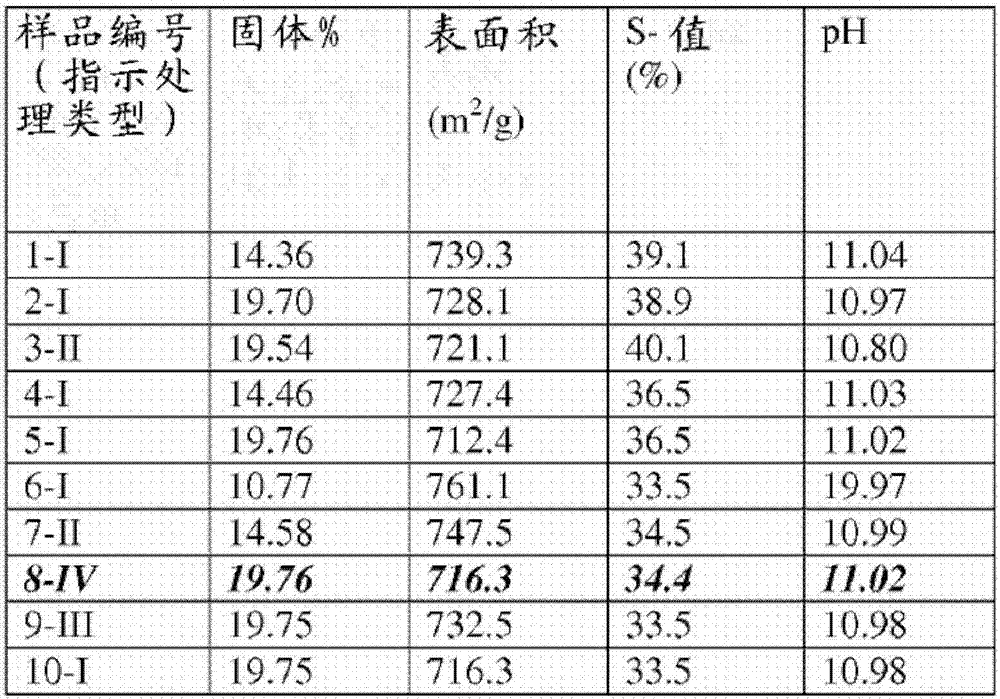

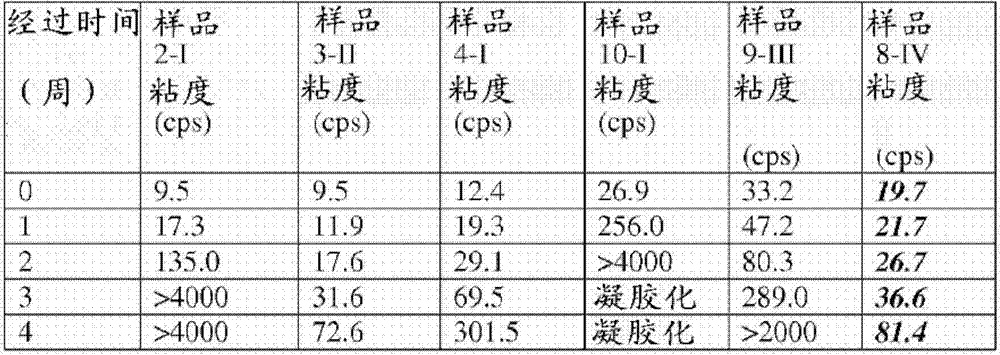

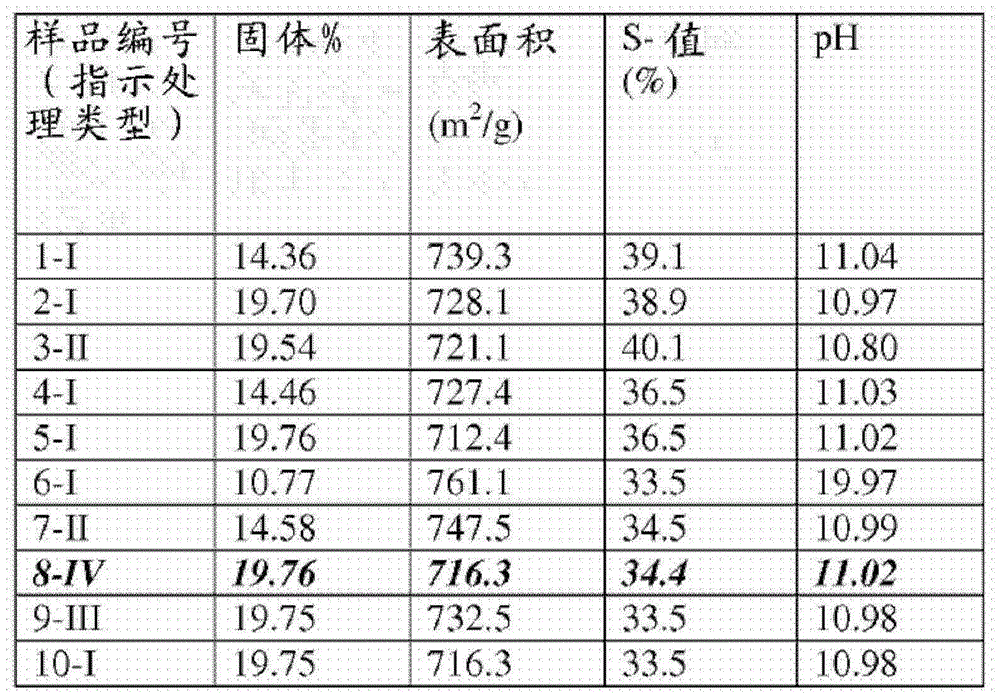

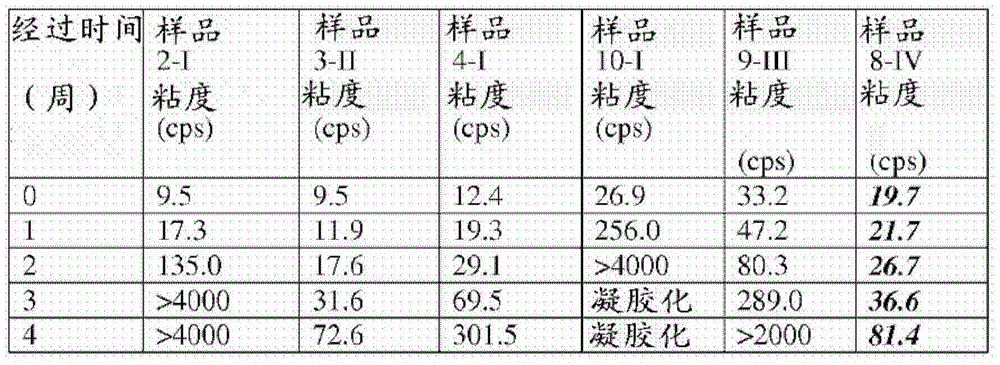

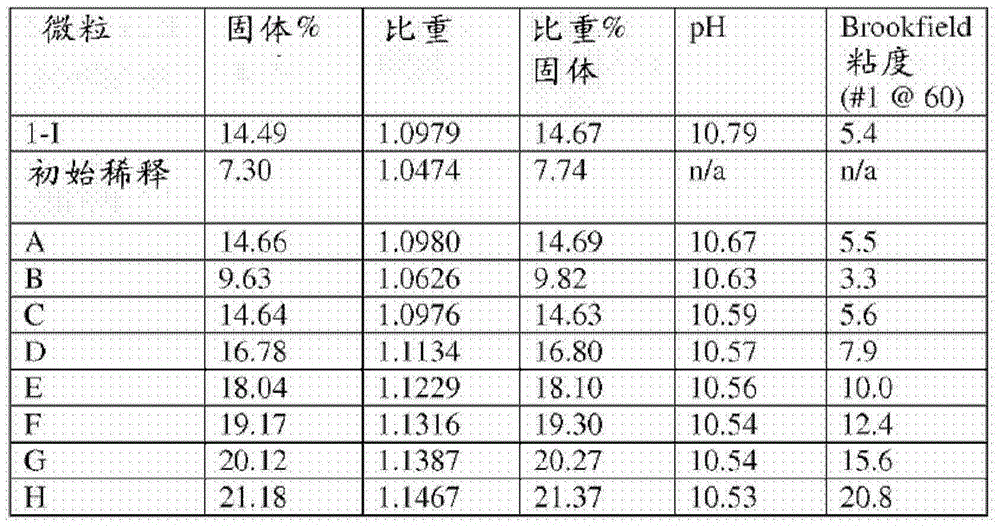

Process for producing high solids colloidal silica

ActiveUS20140251565A1Improve performanceImpairing stabilityNatural cellulose pulp/paperSilicaColloidal silicaCross-link

The invention provides a method for improving the effectiveness of colloidal silica. The method involves removing enough charged impurities from the colloid to prevent the charged particles from causing the colloid to become a viscous gel. The method however also involves not removing too many charged particles so the silica material doesn't gel by cross-linking with itself. This method is quite effective because it recognizes that materials that have accumulated during the formation of the colloid do perform an important function, but they can perform better at a lower concentration.

Owner:ECOLAB USA INC

Method of cleaning silicon nitride layer

InactiveUS7468325B2Efficient removalSemiconductor/solid-state device manufacturingSemiconductor devicesZeta potentialOptoelectronics

A method of cleaning a silicon nitride layer on a substrate is provided to effectively remove negative-charged impurities such as polymer and particle from the silicon nitride layer. In the method, the zeta potential of the silicon nitride layer is changed from positive to negative, and then the silicon nitride layer is cleaned with a first solution selected from an alkali solution and an NC-2 solution. So the negatively-charged impurities can be easily removed due to a repulsion force. The substrate can be treated with spin scrubber or quick dump rinse before and / or after the changing of the zeta potential. To change the zeta potential, the substrate can be dipped into a second solution such as an SC-1 solution, an NC-2 solution, and an alkali solution.

Owner:DONGBU ELECTRONICS CO LTD

Method for preparing lignin-based dispersing agent by purifying pulping black liquor through capacitive deionization method

ActiveCN106432750AFacilitate subsequent modificationEfficient removalDyeing processLiquid productCapacitive deionization

The invention discloses a method for preparing a lignin-based dispersing agent by purifying pulping black liquor through a capacitive deionization method. The preparation method comprises the following steps of (1), adding the pulping black liquor into a reactor, removing a charged impurity in the pulping black liquor with a direct-current voltage of 1.0V to 3.0V by using an electrode, making the pulping black liquor flow through the electrode at a flow speed of 0.1m / min to 0.5m / min, interrupting a power supply once per 5min to 30min to clean the electrode, then recycling the electrode again, and treating a raw material of the pulping black liquor; (2), adding the pulping black liquor from which the charged impurity is removed into another reactor, raising temperature to 60 to 80 DEG C, adding an oxidant into the another reactor, making an obtained first mixture react for 0.5h to 2.0h, afterwards, adding an aldehyde type compound into the another reactor, making an obtained second mixture react for 0.5h to 3.0h at 60 to 100 DEG C, then adding a sulfonating agent into the another reactor, making an obtained third mixture react for 2.0h to 5.0h at 90 to 130 DEG C, then regulating the PH (Potential of Hydrogen) of a reaction system to be 11 to 13, adding sodium hypophosphite into the another reactor, making an obtained fourth mixture react for 1.0h to 4.0h at 80 to 120 DEG C, then adding a quaternizing agent into the another reactor, making an obtained fifth mixture react for 1.0h to 4.0h, then carrying out cooling and discharging to obtain a black-brown liquid product, and drying the black-brown liquid product, so that powder of the lignin-based dispersing agent is obtained.

Owner:FUZHOU UNIV

Direct formation of hexagonal boron nitride on silicon based dielectrics

A scalable process for fabricating graphene / hexagonal boron nitride (h-BN) heterostructures is disclosed herein. The process includes (BN)xHy-radical interfacing with active sites on silicon nitride coated silicon (Si3N4 / Si) surfaces for nucleation and growth of large-area, uniform and ultrathin h-BN directly on Si3N4 / Si substrates (B / N atomic ratio=1:1.11±0.09). Further, monolayer graphene van der Waals bonded with the produced h-BN surface benefits from h-BN's reduced roughness (3.4 times) in comparison to Si3N4 / Si. Because the reduced surface roughness leads to reduction in surface roughness scattering and charge impurity scattering, therefore an enhanced intrinsic charge carrier mobility (3 folds) for graphene on h-BN / Si3N4 / Si is found.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

Process for producing high solids colloidal silica

The present invention provides methods for improving the effectiveness of colloidal silicon dioxide. The method includes removing enough charged impurities from the colloid to prevent the charged particles from turning the colloid into a viscous gel. However the method also includes not removing so many charged particles that the silica material does not gel by cross-linking with itself. This approach is quite effective because it is recognized that aggregated materials do exhibit important functions during colloid formation, but that they may perform better at lower concentrations.

Owner:ECOLAB USA INC

Direct formation of hexagonal boron nitride on silicon based dielectrics

A scalable process for fabricating graphene / hexagonal boron nitride (h-BN) heterostructures is disclosed herein. The process includes (BN)XHy-radical interfacing with active sites on silicon nitride coated silicon (Si3N4 / Si) surfaces for nucleation and growth of large-area, uniform and ultrathin h-BN directly on Si3N4 / Si substrates (B / N atomic ratio=1:1.11±0.09). Further, monolayer graphene van der Waals bonded with the produced h-BN surface benefits from h-BN's reduced roughness (3.4 times) in comparison to Si3N4 / Si. Because the reduced surface roughness leads to reduction in surface roughness scattering and charge impurity scattering, therefore an enhanced intrinsic charge carrier mobility (3 folds) for graphene on h-BN / Si3N4 / Si is found.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

Manufacturing method of mask structure

ActiveCN106486345BQuality improvementSemiconductor/solid-state device manufacturingTectorial membraneEngineering

The invention provides a manufacturing method of a mask structure. The manufacturing method comprises the steps of: providing a mask plate which comprises a substrate and a pattern metal layer arranged on the substrate; providing a protective film device which comprises a bracket and a protective film adhered to the top part of the bracket, wherein the bracket comprises a plurality of supporting side walls, the plurality of supporting side walls are connected with one another to form a closed structure, and an opening is formed in one supporting side wall; placing the protective film device in an electrostatic field, and blowing a charged gas into the opening; and moving the protective film device away from the electrostatic field, and adhering the pattern metal layer on the bottom part of the bracket. Before adhering the bracket with the pattern metal layer, the gas is blown into the opening so that impurities at the opening are blown off; and the protective film device is placed in the electrostatic field generated by an electrostatic generation device, and the blown-off and charged impurities are absorbed and away from the protective film device under the action of the electrostatic field, thus the impurities at the opening are removed, and the quality of the mask plate is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for filtering medicinal fluid impurities

InactiveCN104310656AWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisIon exchangePorous membrane

The invention discloses a method for filtering medicinal fluid impurities. The method comprises the following steps: enabling the medicine to pass through a porous membrane comprising various exchange resins before medicine is used, wherein the exchange resins are porous ion exchange resins capable of removing materials with charges of different signs in a fluid, and the sizes of resin particles after being smashed is 12-50 microns, and the median particle diameters of the resin particles are about 40 microns; when the membrane is at the temperature of 90 DEG C, the fluid with charged impurities of smaller than 500 ppb is provided, in water with a flow rate of 7000-9000 cm<3> / min, the amount of anionic or cationic impurities of the treated fluid is smaller than 5 ppbv / v, the polymeric material of the porous membrane comprises the mixture of polypropylene and polyethylene, and the porous membrane is a fusion casting forming membrane structurally. The method is good in filter effect and high in speed.

Owner:华文蔚

Superconductivity based on bose-einstein condensation of electron or electron-hole pairs in semiconductors

ActiveUS7968352B2Alleged superconductivity devicesSemiconductor/solid-state device manufacturingBinding energyElectron hole

The invention describes a method of achieving superconductivity in Group IV semiconductors via the addition of doubly charged impurity atoms to the crystal lattice. The doubly charged impurities function as composite bosons in the semiconductor. Increasing the density of the composite bosons to a level where their wavefunctions overlap, results in the formation of a Bose condensate. The concentration of the doubly charged impurity atoms in the host lattice and the binding energy of the impurities are important factors in determining whether a Bose condensate will form. Doubly charged impurities must be present in the semiconductor at a concentration at which they exhibit overlapping wavefunctions, but still exist within the crystal lattice as bosons.

Owner:WISE WILLIAM G

Graphene composite material for photoconversion and energy storage and preparation method

ActiveCN106058253ALow costSimple processMaterial nanotechnologyCell electrodesIon exchangeCharged impurity

The invention discloses a graphene composite material for photoconversion and energy storage and a preparation method. The method comprises the steps of: employing graphite as a raw material, firstly, infiltrating phenyl ammonium salt cations between graphite layers; introducing positively charged impurities between the graphite layers through the electrophilic effect of a pi bond between the graphite layers, blending the positively charged impurities and a metal cation salt and carrying out ion exchange reaction on a benzyl ammonium salt and the metal cation salt; and decomposing the salt through warming to obtain nano metal oxide particles under the protection of an inert gas. The problems that graphene and the oxide particles are easily agglomerated and cannot be evenly dispersed, the preparation technology is complicated, the equipment requirement is high and the like in the prior art are solved. Two processes of mechanical stripping and nano material compounding are merged into one, so that the cost is greatly reduced; the technology is simplified; and the preparation method is suitable for a continuous industrial production technology, compatible with a technology for mechanically stripping the graphene and suitable for partial established companies for direct production.

Owner:齐河智谷产业发展有限公司

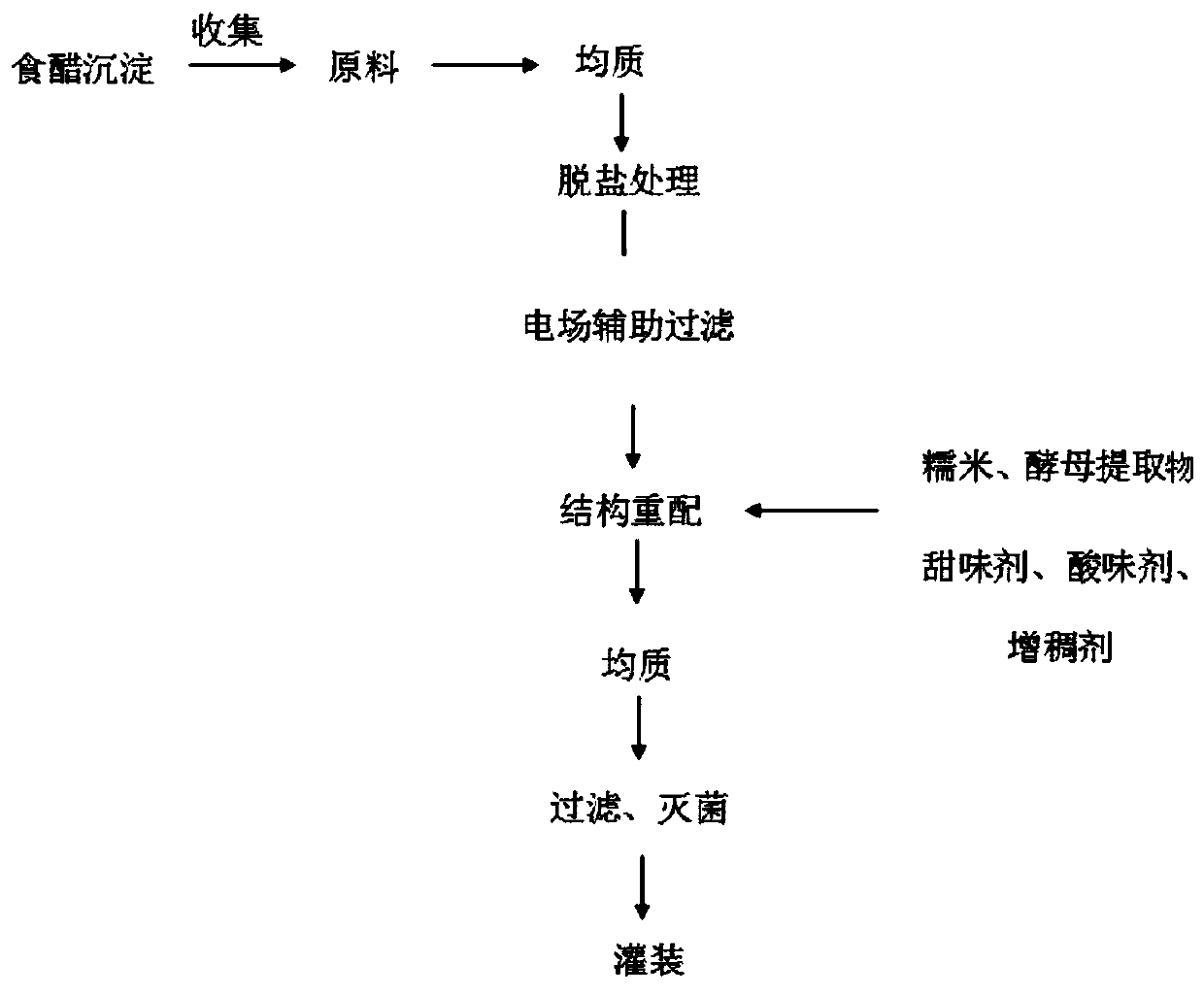

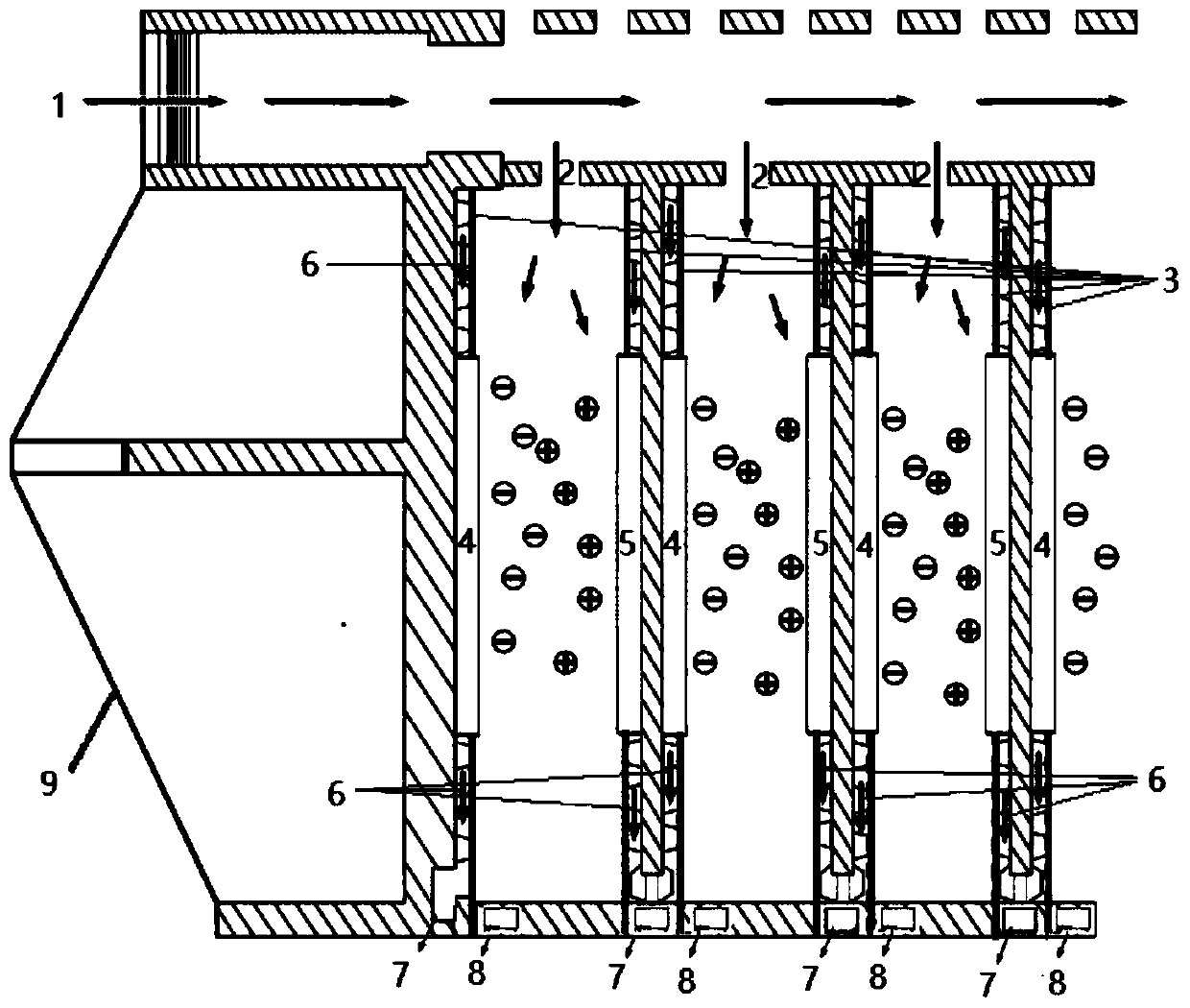

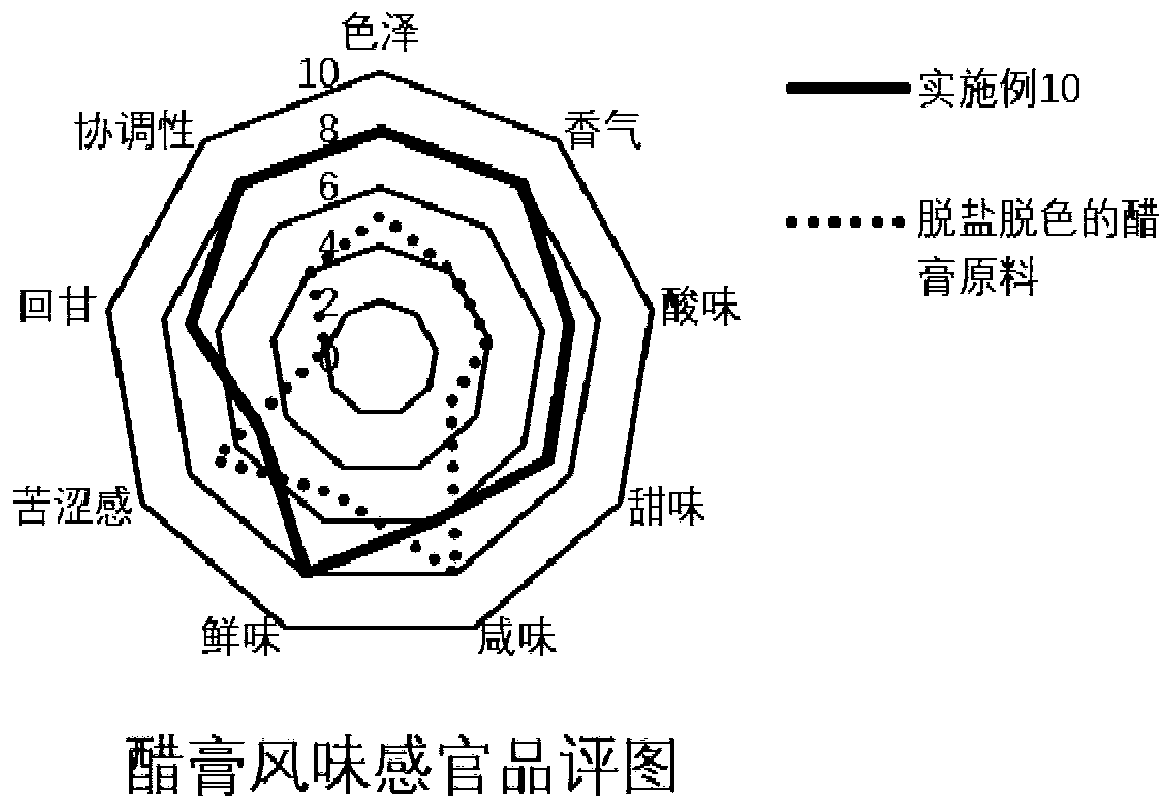

Vinegar paste and preparation method thereof

ActiveCN110584061ARealize comprehensive utilizationReduce lossesClimate change adaptationFood scienceDesalinationAdditive ingredient

The invention relates to the technical field of food, in particular to vinegar paste prepared from table vinegar precipitate and a preparation method thereof. The method comprises the following steps:selecting aged table vinegar, removing vinegar liquid which is 2-3cm away from a table vinegar precipitate, collecting a sample, carrying out heat treatment, carrying out colloid mill treatment afterthe sample is cooled to 20-40 DEG C, and then performing homogenizing; and finally, performing desalting by adopting plate-and-frame filtering equipment with an external electric field to obtain thevinegar paste. According to the method, the vinegar precipitate is desalted to realize comprehensive utilization of resources, charged impurities are removed by using a secondary electric field-assisted method, and secondary desalination is carried out by adjusting the pH value of the raw materials, so that the optimal desalination effect is achieved, the loss of charged compounds such as amino acid is reduced, and the nutritional ingredients of the vinegar paste are reserved to the maximum extent.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Vacuum deposition method of organic molecules

ActiveCN108906363AImprove transmittanceIncrease mass flow outputLiquid spraying plantsLiquid surface applicatorsMass ratioNitrogen gas

The invention relates to the field of material preparation, and discloses a vacuum deposition method of organic molecules. The vacuum deposition method of organic molecules comprises the steps that high-purity nitrogen is fed through a gas inlet while the flow pattern is 5.0 SLM, and a solution is fed through a liquid inlet while the flow pattern is 20 mL / M; voltage is applied between an outer pipe and an inner pipe to turn part of molecules, to be deposited, in the solution into ions so as to make the solution form atomized liquid drops, the voltage is regulated, and rotation of a baffle is regulated to change the relative position of the baffle to a groove so as to control jet beams; the position of an electrospray device is adjusted, and the number of the atomized liquid drops enteringthe vacuum chamber through capillary tubes is adjusted; ion packages and impurities of molecules to be deposited in liquid drops pass through a first ion beam buncher; ion packages and impurities of molecules to be deposited pass through a second ion beam buncher to enable ion beams further gather; the ion packages and the impurities arrive at an electrostatic deflector; and after charge-to-mass ratio selection, charged impurities are deflected and collide with a pole plate of a quadrupole mass filter to be filtered out, and finally, only the ion packages of the molecules to be deposited arrive at the surface of a substrate.

Owner:JINHUA VOCATIONAL TECH COLLEGE

A kind of extraction, separation and purification process of water chestnut polysaccharide

ActiveCN106146685BOvercome the disadvantage of low extraction rateThere is no safety problem in the use of strong alkaliBulk chemical productionAlkaline proteaseLow ionic strength

The invention discloses an extraction, separation and purification process of brasenia schreberi polysaccharide. According to the process, the supercritical CO2 extraction technology is utilized, the defect that the extraction rate is low through a hot water extraction method and a NaOH extraction method is overcome, and the safety problem appearing in the situation that strong base needs to be used in NaOH extraction does not exist. When a crude product of the brasenia schreberi polysaccharide is purified, alkaline protease is adopted for treating and removing protein; cetyl trimethyl ammonium bromide and the brasenia schreberi polysaccharide can form quaternary amine complexes, the complexes do not dissolve in an aqueous solution with a low ionic strength and can dissociate and dissolve when the ionic strength is high, and the separation and purification effect is better; by using 312 weak-acid anionic exchange resin chromatography, some positively-charged impurities can be removed, and the separation and purification effect is better.

Owner:CHONGQING THREE GORGES MEDICAL COLLEGE

A kind of graphene composite material and preparation method for light conversion energy storage

ActiveCN106058253BLow costSimple processMaterial nanotechnologyCell electrodesIon exchangeCharged impurity

The invention discloses a graphene composite material for photoconversion and energy storage and a preparation method. The method comprises the steps of: employing graphite as a raw material, firstly, infiltrating phenyl ammonium salt cations between graphite layers; introducing positively charged impurities between the graphite layers through the electrophilic effect of a pi bond between the graphite layers, blending the positively charged impurities and a metal cation salt and carrying out ion exchange reaction on a benzyl ammonium salt and the metal cation salt; and decomposing the salt through warming to obtain nano metal oxide particles under the protection of an inert gas. The problems that graphene and the oxide particles are easily agglomerated and cannot be evenly dispersed, the preparation technology is complicated, the equipment requirement is high and the like in the prior art are solved. Two processes of mechanical stripping and nano material compounding are merged into one, so that the cost is greatly reduced; the technology is simplified; and the preparation method is suitable for a continuous industrial production technology, compatible with a technology for mechanically stripping the graphene and suitable for partial established companies for direct production.

Owner:齐河智谷产业发展有限公司

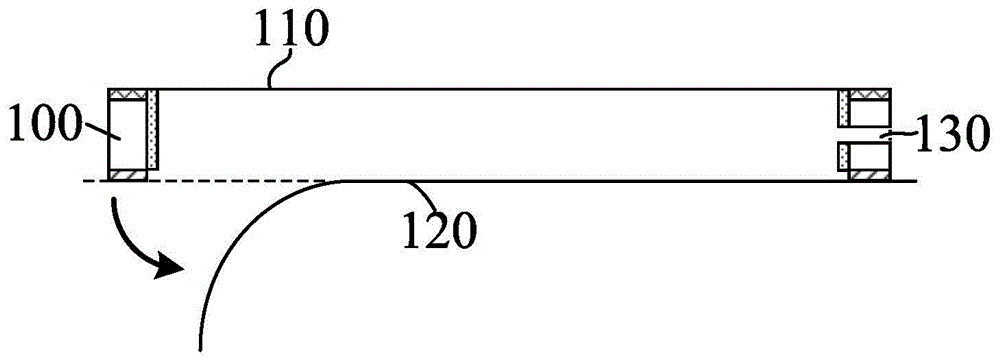

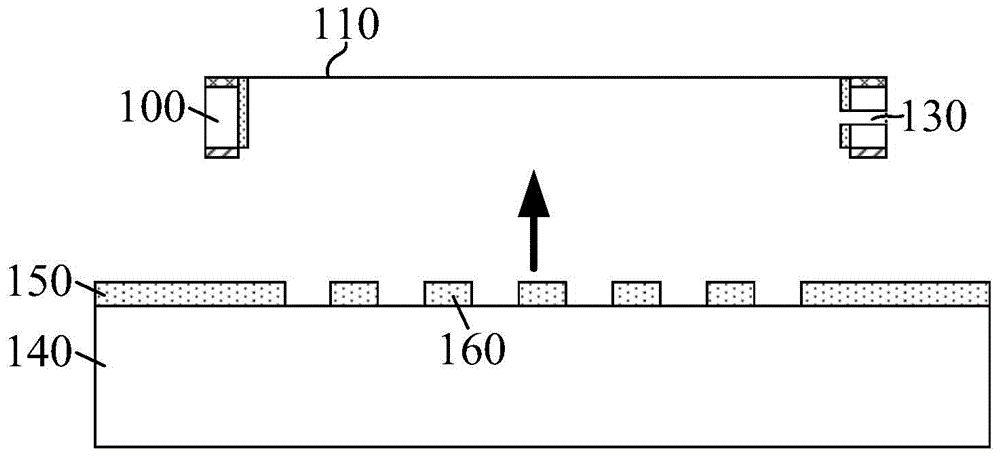

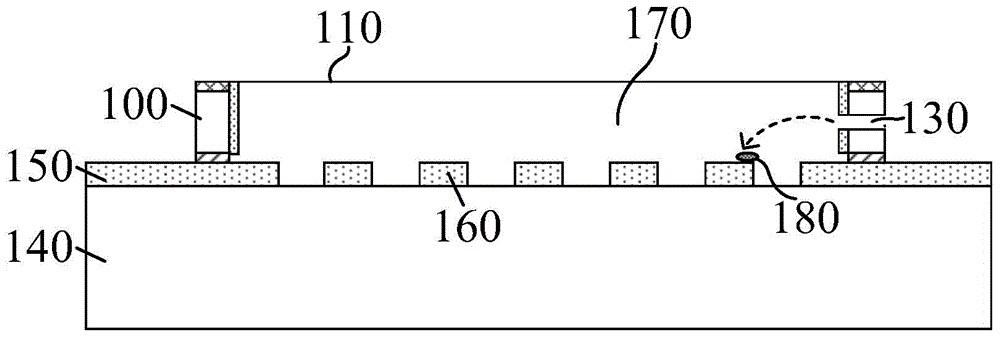

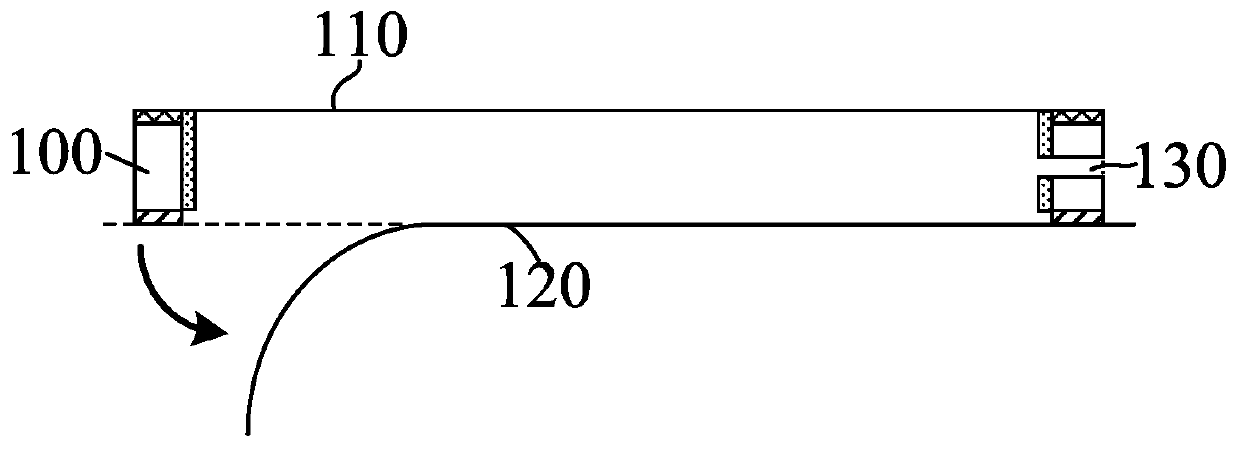

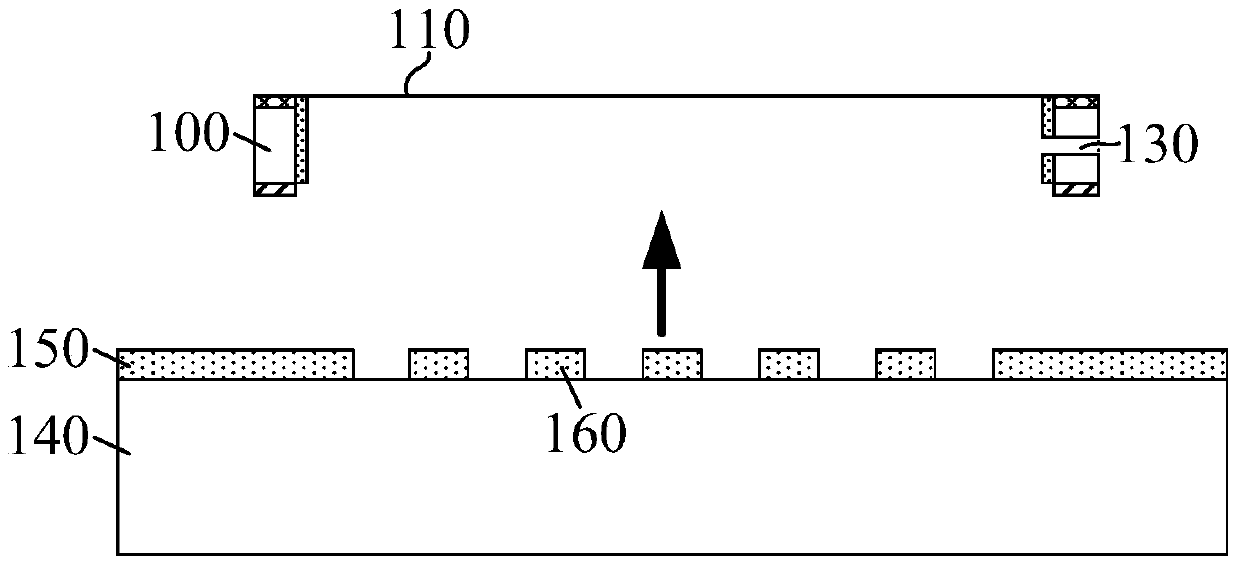

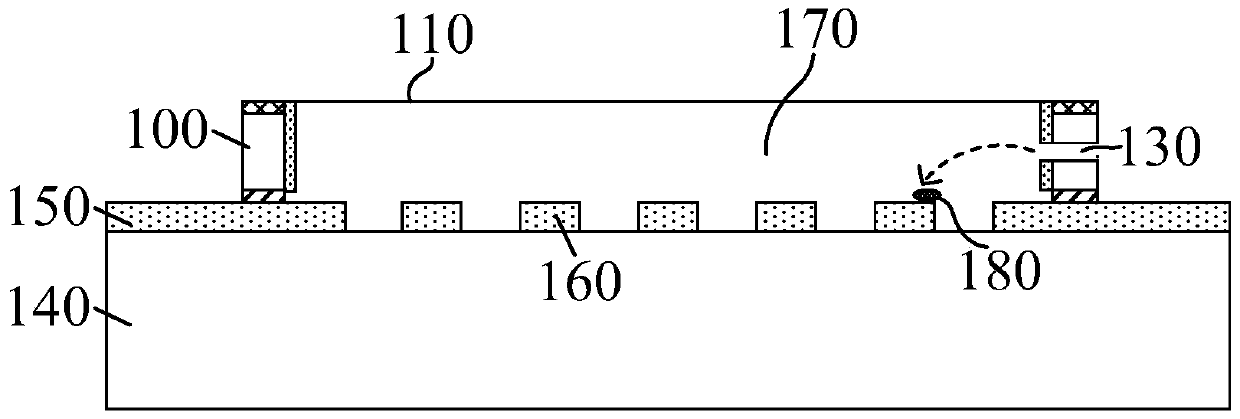

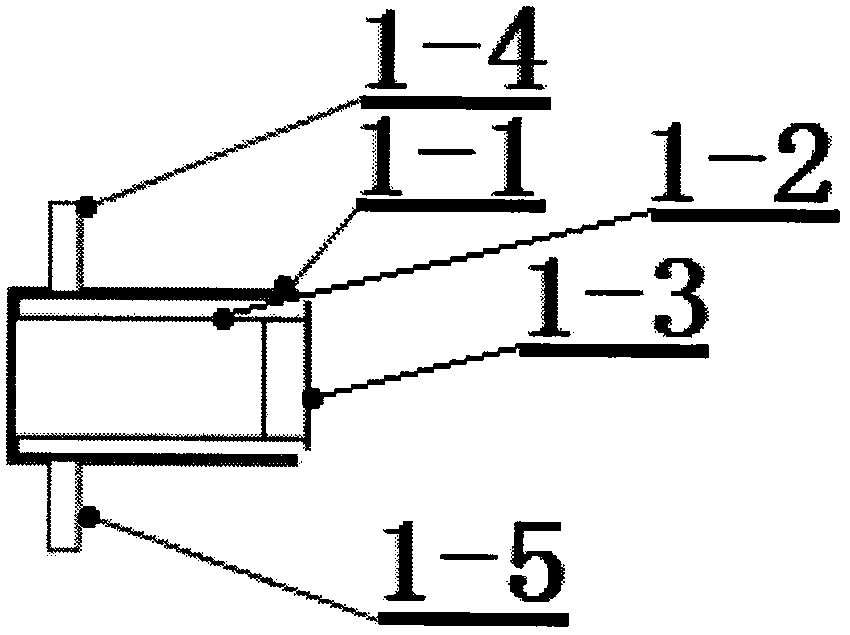

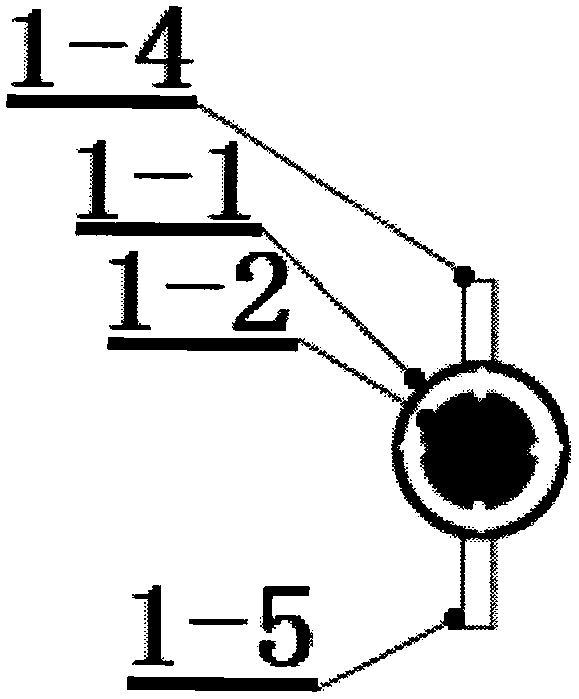

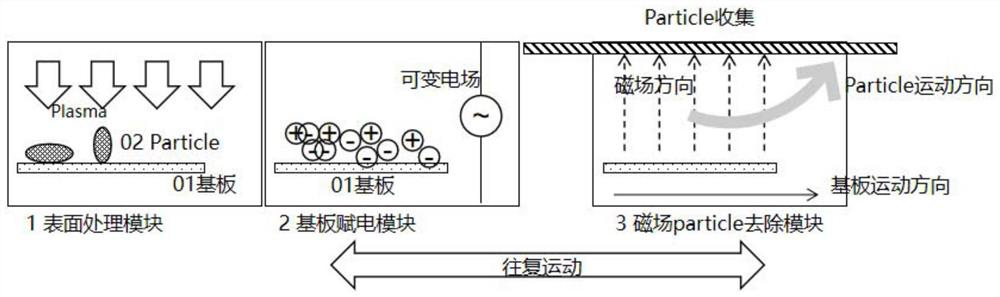

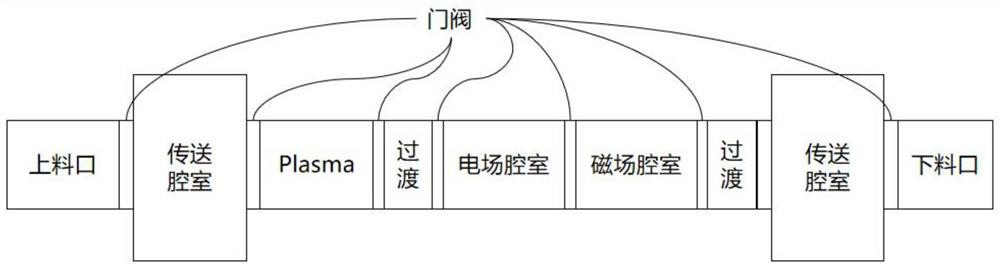

Substrate pretreatment device and method for removing impurity particles of Micro OLED

ActiveCN112864345AReduce foreign particlesImprove yield rateSolid-state devicesSemiconductor/solid-state device manufacturingParticle physicsCharged impurity

The invention discloses a substrate pretreatment device and method for removing impurity particles of a Micro OLED, and the device comprises a surface treatment module which can emit a plasma flow to a substrate; an energizing module capable of adding charges to impurity particles on the substrate; a magnetic field module which can apply electromagnetic force to the charged impurity particles on the substrate; and a conveying mechanism which can convey the substrate in the surface treatment module, the energizing module and the magnetic field module. The substrate can reciprocate between the energizing module and the magnetic field module, impurity particles on the surface of the substrate are reduced, the product yield is improved, meanwhile, the surface energy of the substrate can be reduced while charges are applied to the surface of the substrate, and the subsequent interface contact is tighter.

Owner:ANHUI SEMICON INTEGRATED DISPLAY TECH CO LTD

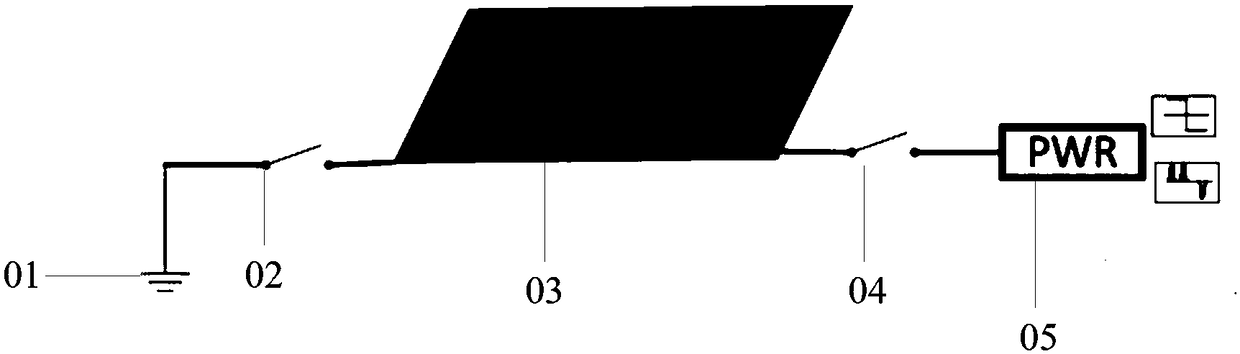

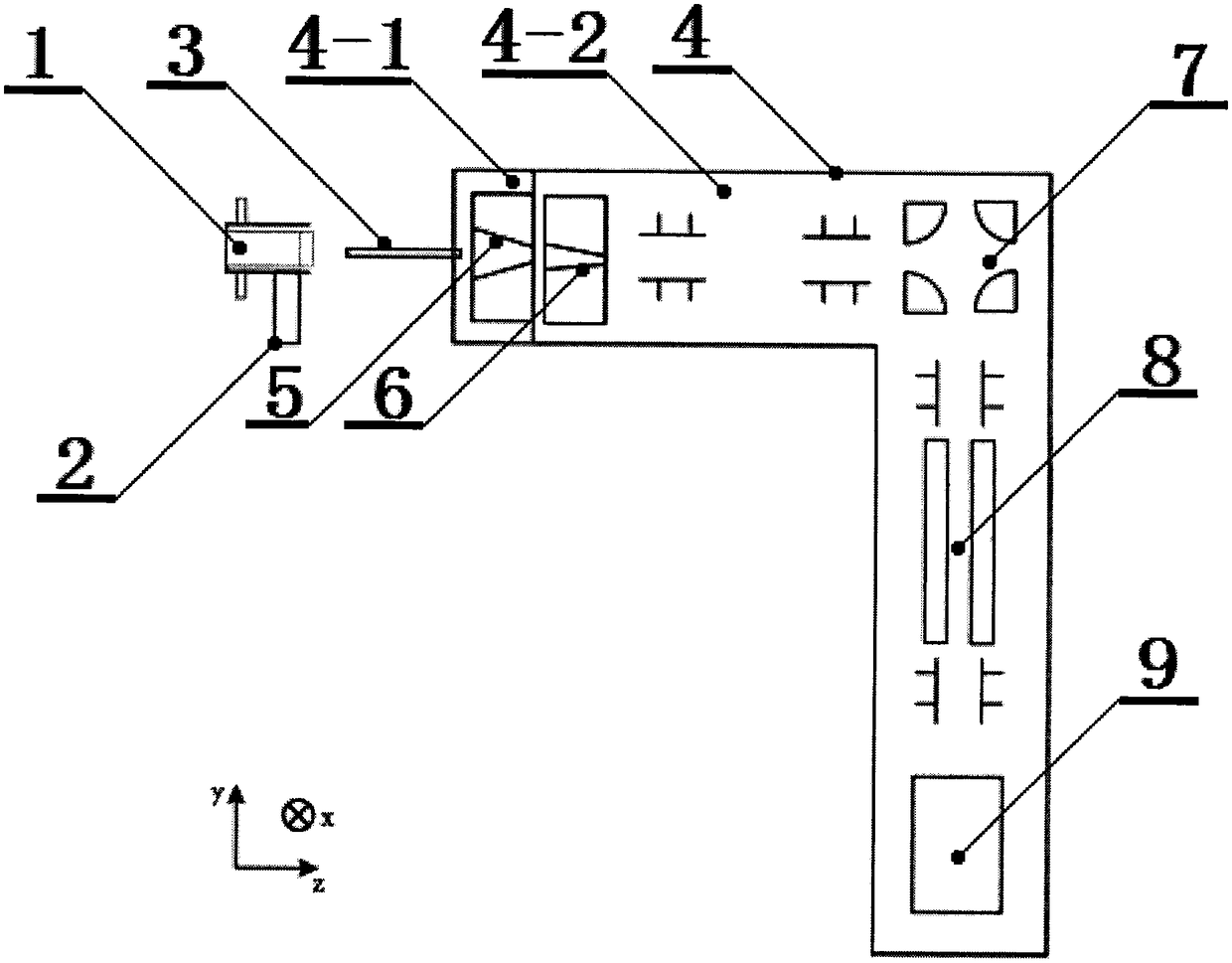

Method for assisting polycrystalline silicon ingot casting by electrostatic field

InactiveCN107164802AImprove product qualitySmall sizePolycrystalline material growthSingle crystal growth detailsElectrical field strengthHigh pressure

The invention discloses a method for assisting polycrystalline silicon ingot casting by an electrostatic field. The method includes the steps: (1) placing two electrode plates on the upper side and the lower side of a polycrystalline ingot casting crucible and keeping the two electrode plates parallel; (2) externally connecting the electrode plates with a high-voltage power supply and outputting stable voltage to the electrode plates; (3) keeping electric field intensity stabilized at a certain concrete value within the range of 1V / cm-100000V / cm, and performing a polycrystalline silicon ingot casting process; (4) finishing ingot casting and powering off the electrode plates to obtain a polycrystalline silicon cast ingot with an excellent performance. Polycrystalline silicon grains can be enlarged, orientation is enhanced, various charged impurities in polycrystalline silicon can be efficiently removed, polycrystalline silicon quality is substantially improved, operation is simple, stability is good, and batch production can be performed. A figure 1 is an electric field application diagram in embodiments 1 and 2 and includes a lead 1, a graphite electrode 2, the ingot casting crucible 3 and the high-voltage power supply 4.

Owner:UNIV OF JINAN

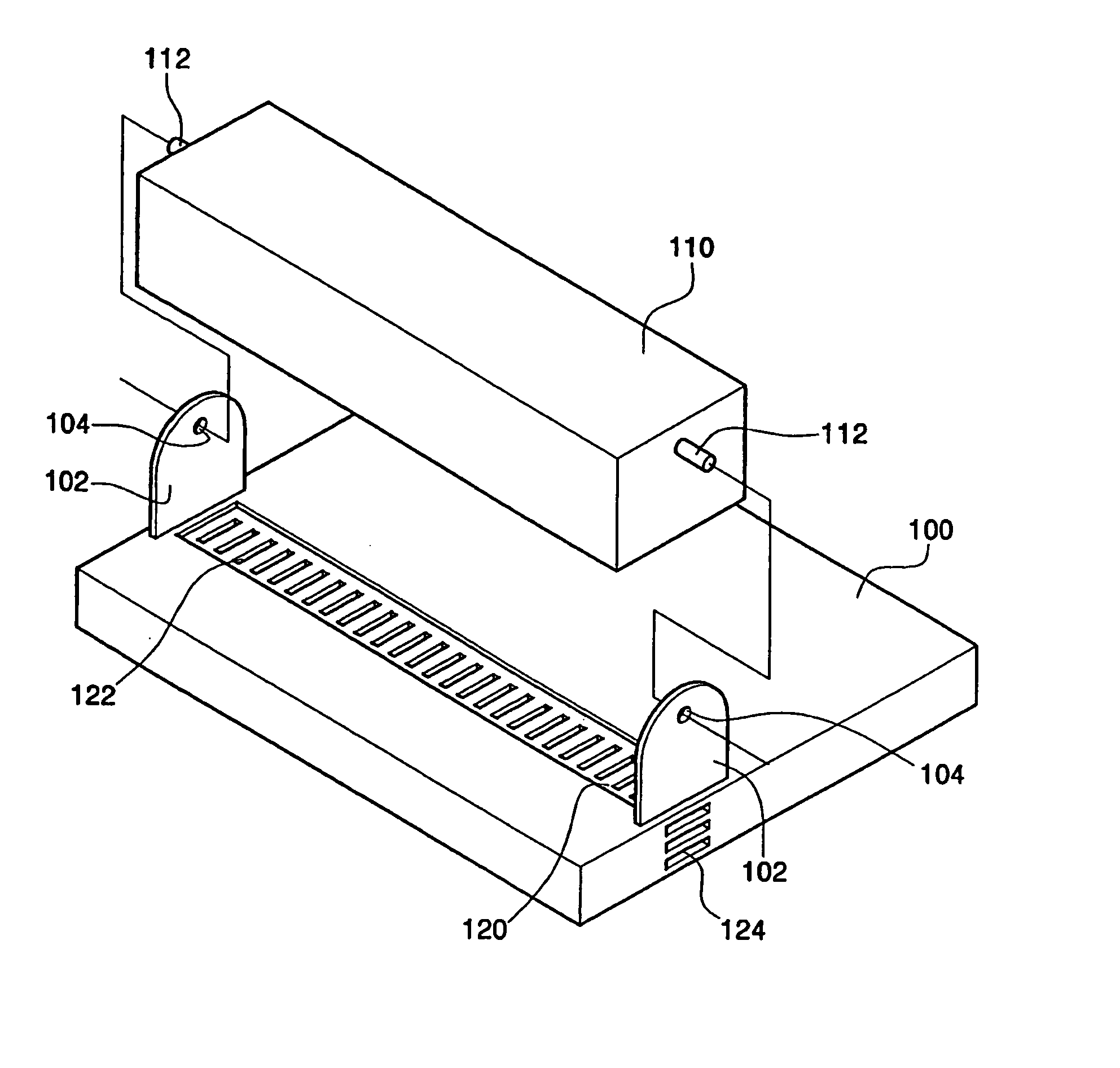

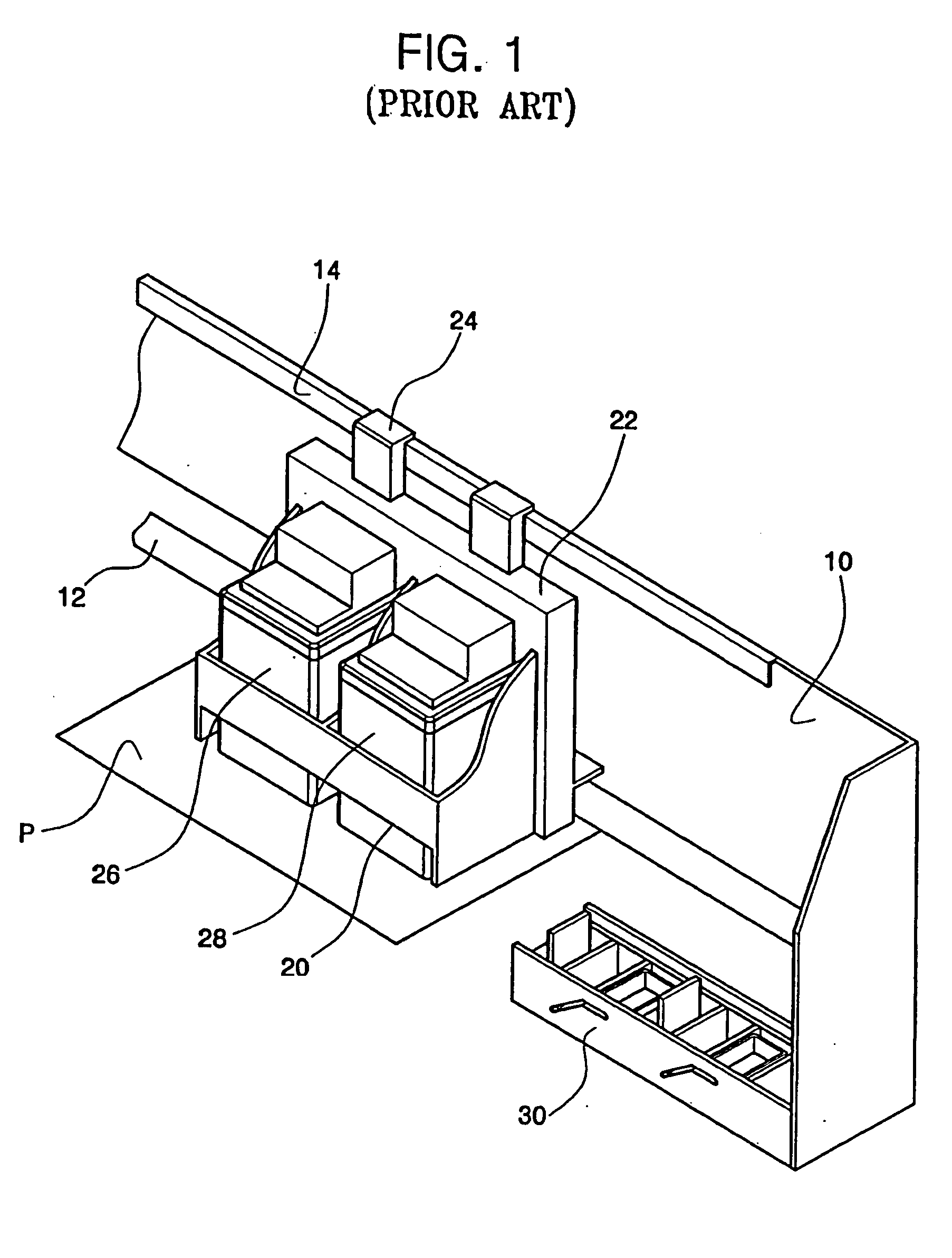

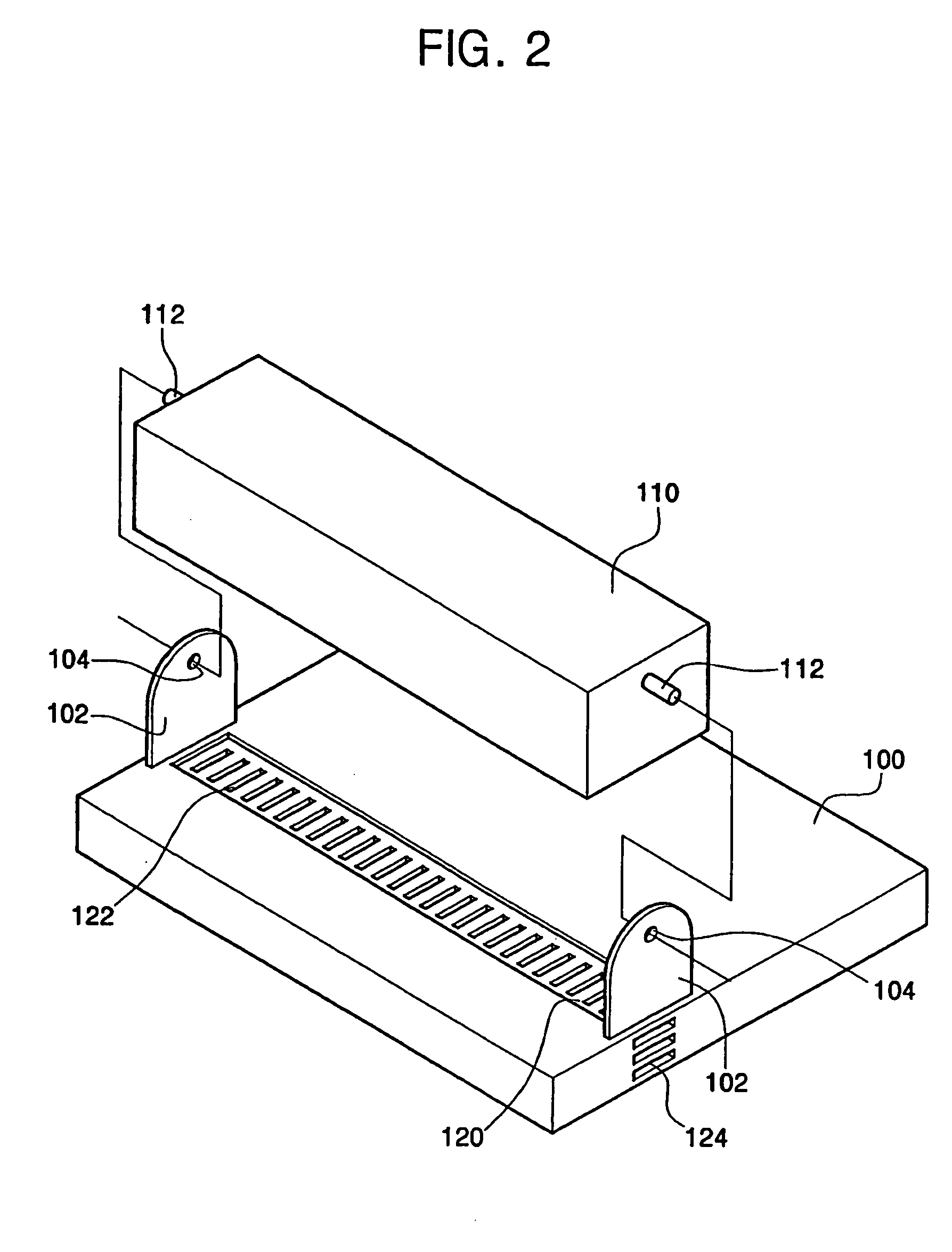

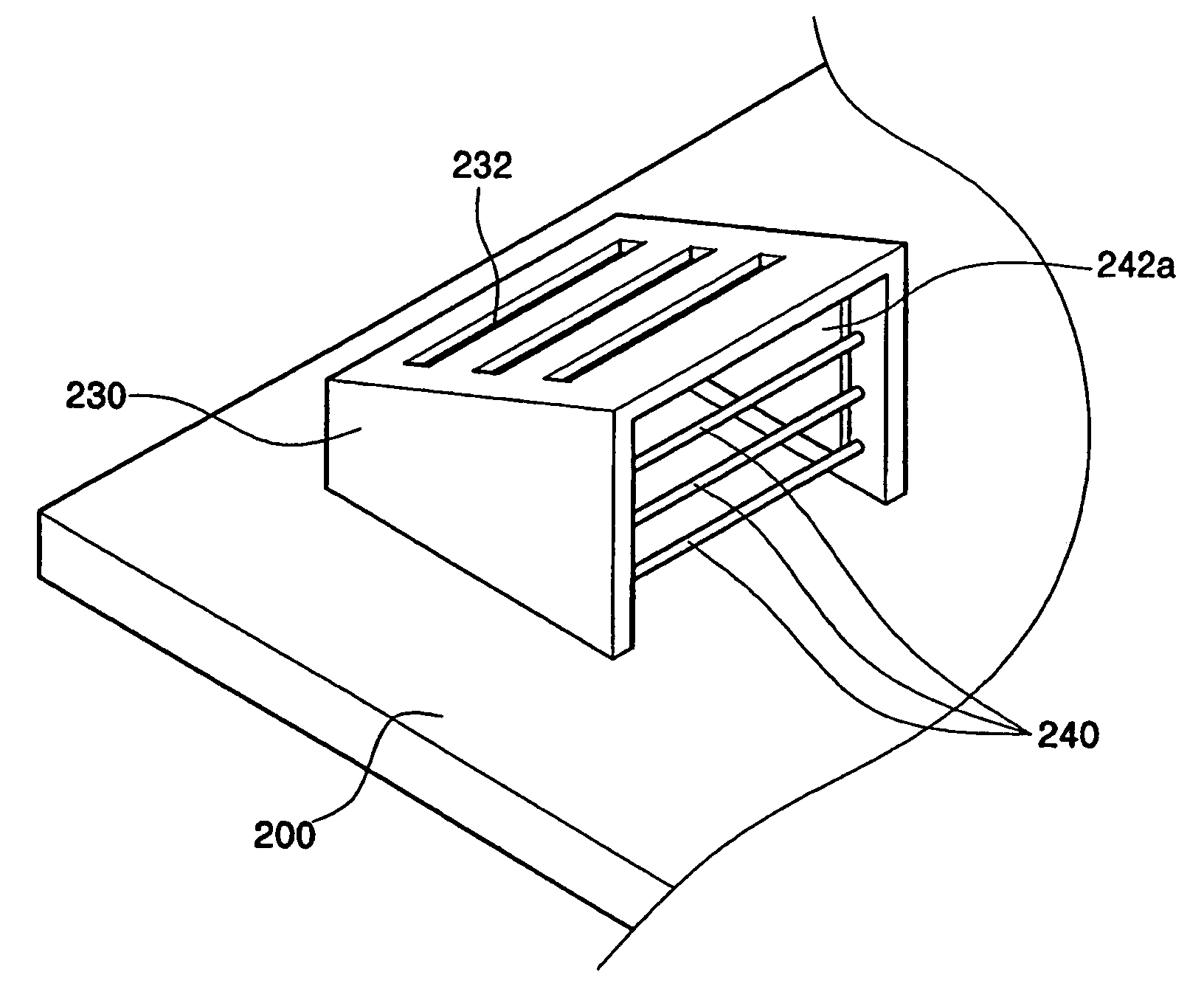

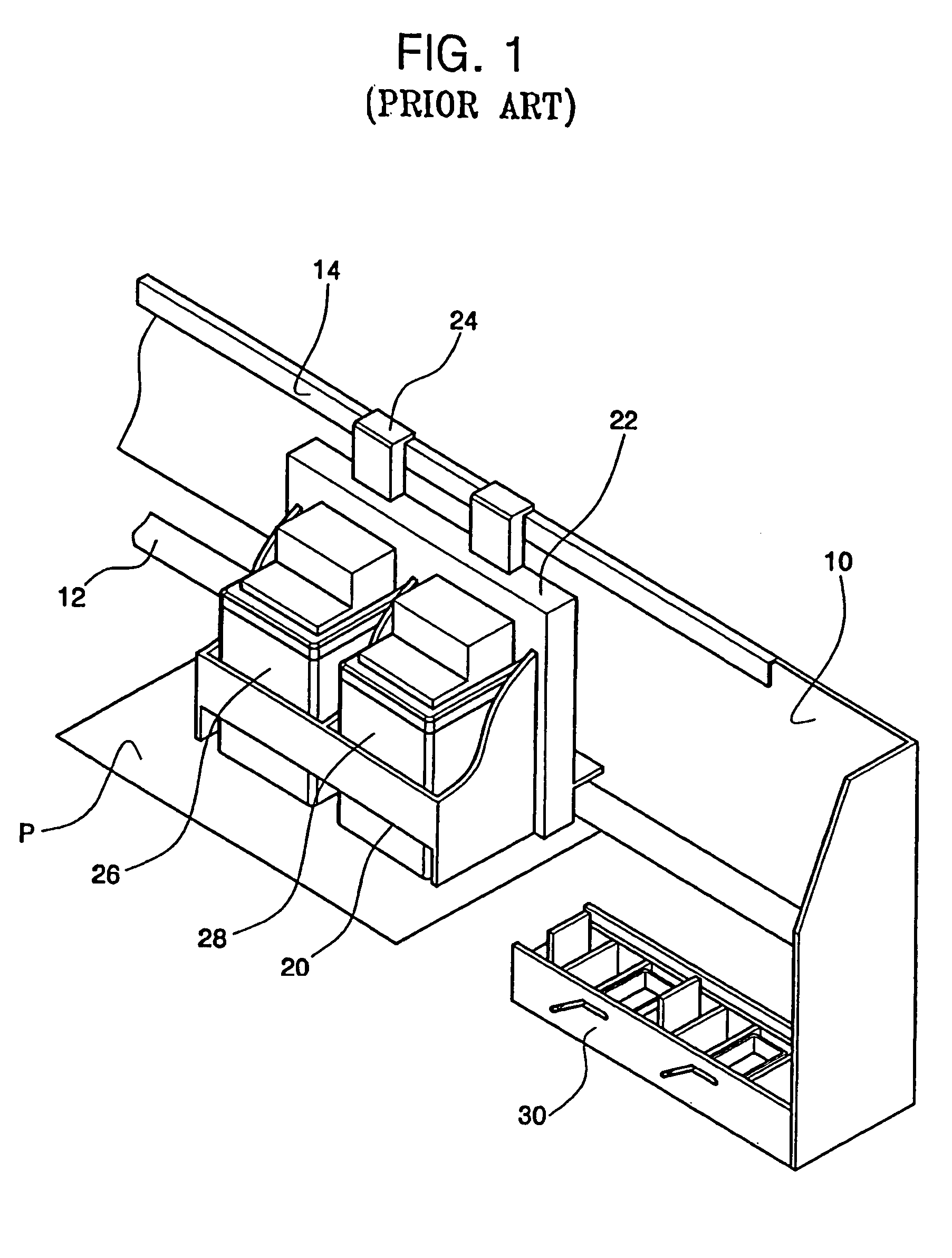

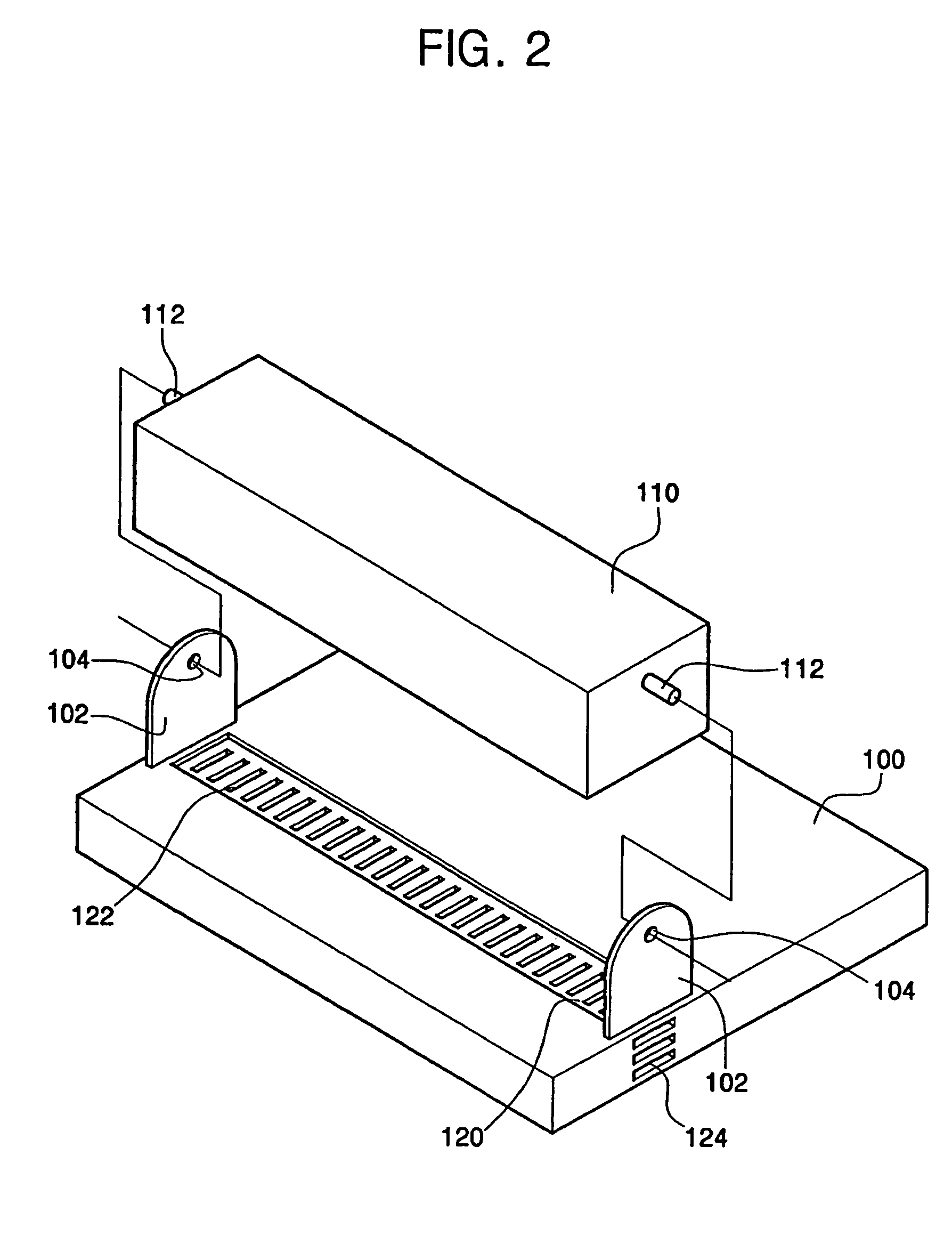

Image forming apparatus with dust collector

InactiveUS20060033786A1Improve air efficiencyImprove adsorption capacityDispersed particle filtrationOther printing apparatusImage formationCharged impurity

An image forming apparatus provided with a dust collecting part includes an ink cartridge having a wide array type ink jet head that is capable of ejecting ink over an entire lateral line that is perpendicular to a conveying direction of a recording medium at a time, and a main body case that supports the ink cartridge, a duct located under the wide array type ink jet head to extend in a longitudinal direction of the wide array type ink jet head; and a dust collecting part including a charging part disposed in the duct to charge impurities and electrodes disposed in the duct to adsorb the charged impurities The image forming apparatus includes a dust-collecting part that adsorbs the impurities over an entire region of the wide array type ink jet head, thereby effectively removing the impurities generated in large quantities and increasing a life span and a reliability of image forming apparatuses, since the dust collecting part is securely maintained during operation.

Owner:S PRINTING SOLUTION CO LTD

A dust collector

ActiveCN104294415BImprove cleanlinessSolve technical problems that cannot be effectively removedLap forming devicesTextile disintegration and recoveryFiberWind driven

The invention discloses a dust-removing cotton fluffer. The dust-removing cotton fluffer comprises a frame, a feeding rack, a cotton feeding roller and a licker-in arranged correspondingly to the cotton feeding roller, wherein the feeding rack is arranged in front of the frame; the cotton feeding roller is arranged on the tail end of the feeding rack; a dust collection chamber is arranged under the licker-in and a fan for collecting dust is connected to the dust collection chamber. The cotton fluffer further comprises a high-voltage power source, wherein one electrode of the high-voltage power source is electrically connected with the external surface of the licker-in, while the other electrode of the high-voltage power source is electrically connected with a dust collection plate arranged in the dust collection chamber; the dust collection plate is directly arranged under the licker-in. the dust-removing cotton fluffer has the advantages that the electric-field dust removal technique is adopted on the basis of existing wind-driven dust removal so that impurities such as dust to have charges opposite to the charges of the dust collection plate in the cotton fiber release process of the licker-in, next, the charged impurities such as dust are adsorbed on the dust collection plate under the action of the electric field between the licker-in and the dust collection plate, and most dust can be removed in combination with the action of a fan, and therefore, the technical problem that the impurities cannot be removed effectively due to the electrostatic interaction is effectively solved and the cleanness of the cotton fibers is remarkably improved.

Owner:盐城美逸家纺有限公司

Process for producing high solids colloidal silica

The invention provides a method for improving the effectiveness of colloidal silica. The method involves removing enough charged impurities from the colloid to prevent the charged particles from causing the colloid to become a viscous gel. The method however also involves not removing too many charged particles so the silica material doesn't gel by cross-linking with itself. This method is quite effective because it recognizes that materials that have accumulated during the formation of the colloid do perform an important function, but they can perform better at a lower concentration.

Owner:ECOLAB USA INC

Image forming apparatus with dust collector

InactiveUS7234794B2Improve adsorption capacityEasy maintenanceDispersed particle filtrationOther printing apparatusImage formationEngineering

Owner:S PRINTING SOLUTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com