Method for assisting polycrystalline silicon ingot casting by electrostatic field

A polycrystalline ingot, polycrystalline silicon technology, applied in the direction of polycrystalline material growth, chemical instruments and methods, crystal growth, etc., can solve problems such as cost reduction, difficult removal of impurity ions, poor crystal quality of polycrystalline silicon crystals, etc. The effect of grain orientation, grain size improvement, and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

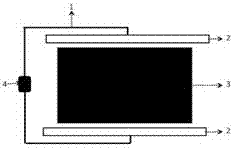

[0015] 1. Place two graphite electrode plates on the upper and lower sides of the polycrystalline ingot crucible and keep them parallel;

[0016] 2. The electrode plate is connected to a high-voltage power supply to output a stable voltage to the electrode plate;

[0017] 3. Keep the electric field strength stable at 10V / cm, and carry out the polysilicon ingot casting process;

[0018] 4. When the ingot is finished, the pole plate is cut off, and the polysilicon ingot with excellent performance is obtained.

Embodiment 2

[0020] 1. Place the two silicon carbide electrode plates on the upper and lower sides of the polycrystalline ingot crucible and keep them parallel;

[0021] 2. The electrode plate is connected to a high-voltage power supply to output a stable voltage to the electrode plate;

[0022] 3. Keep the electric field strength stable at 100V / cm, and carry out the polysilicon ingot casting process;

[0023] 4. When the ingot is finished, the pole plate is cut off, and the polysilicon casting with excellent performance is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com