Vacuum deposition method of organic molecules

A technology of vacuum deposition and organic molecules, applied to the surface coating liquid device, spray discharge device, liquid spraying equipment, etc., can solve the problems of low ion transmittance, low mass flow output of electrospray, etc., to increase the transmittance , increase the mass flow output, change the effect of the spray shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

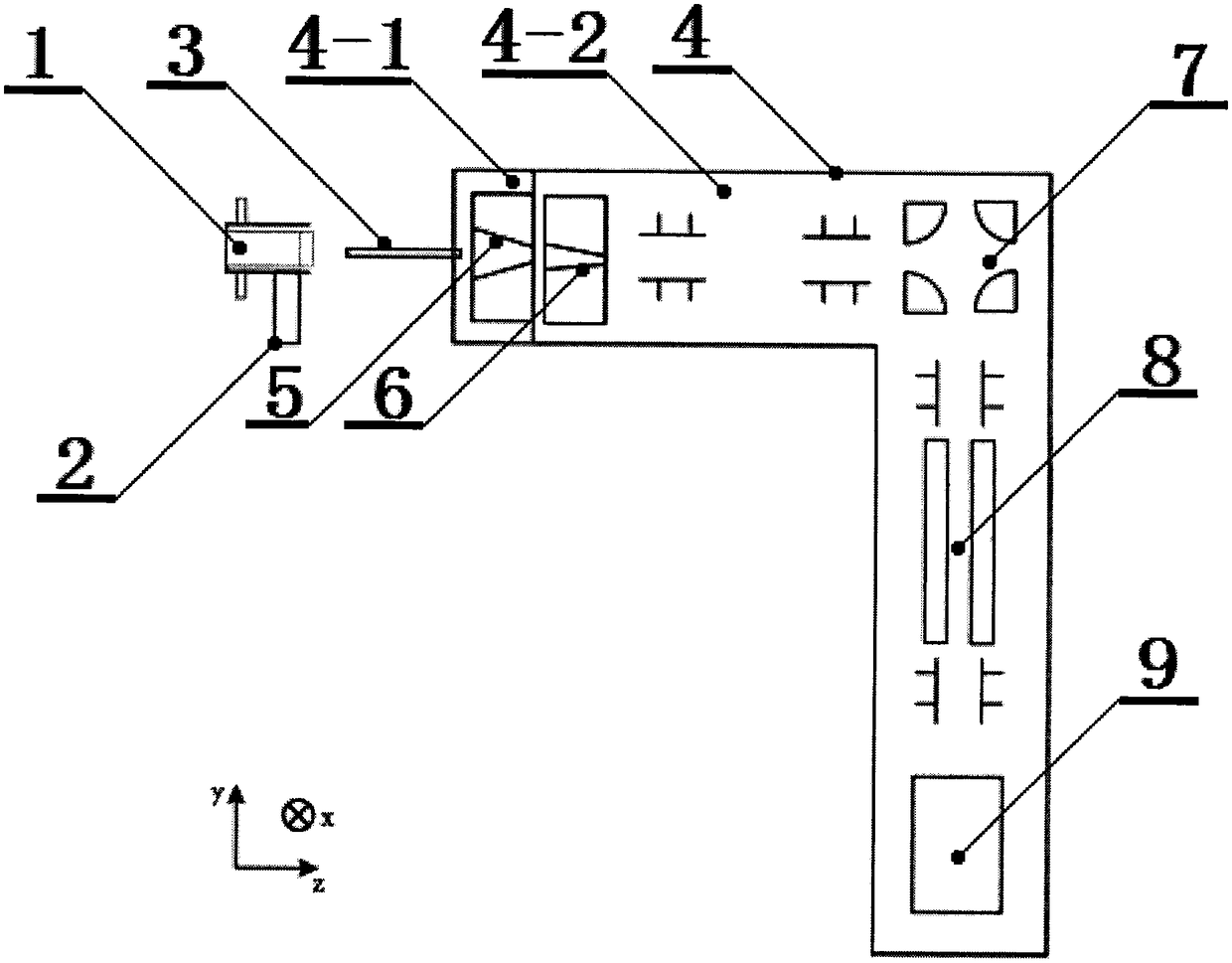

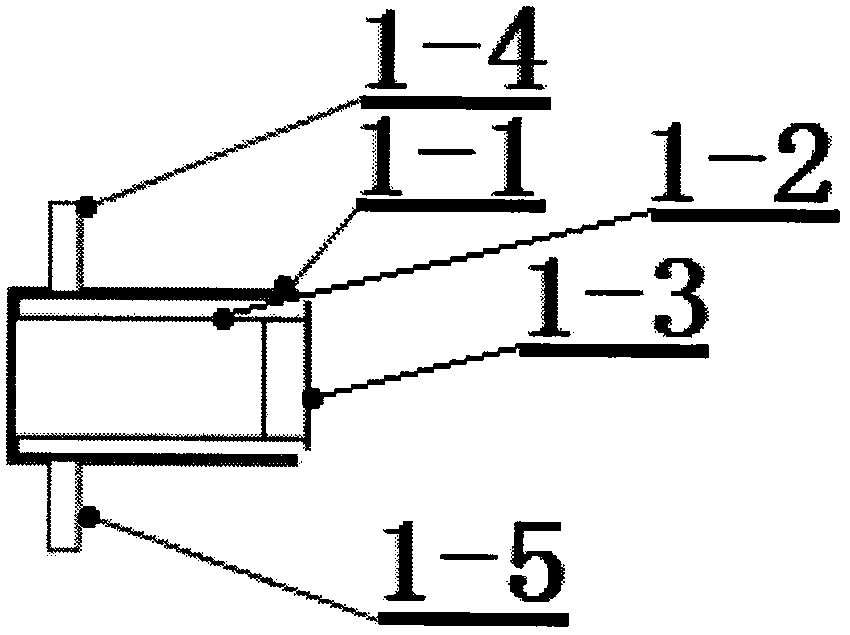

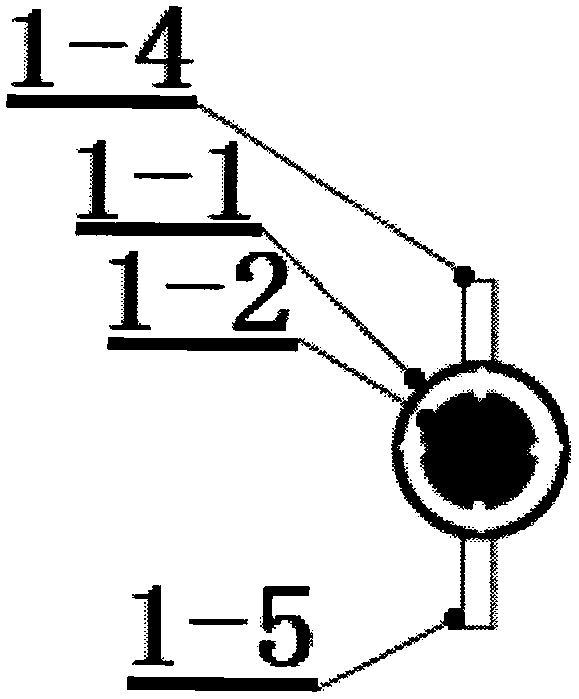

[0022] Such as figure 1 It is a schematic diagram of the present invention, and the vacuum deposition device of organic molecules mainly includes an electrospray device (1), a displacement stage (2), a capillary (3), a vacuum cavity (4), an ion buncher I (5), an ion buncher Device II (6), electrostatic deflector (7), quadrupole mass filter (8) and sample stage (9), xyz is the three-dimensional coordinate system, and the electrospray device (1) is installed on the displacement stage (2) to be capable of three-dimensional Move, the vacuum chamber (4) is formed by connecting two sections of cylindrical vacuum chambers at 90 degrees, and has an initial end and an end. The ion beamer I (5), ion beamer II (6) , electrostatic deflector (7), quadrupole mass filter (8), and sample stage (9) are all located in the vacuum chamber (4) in sequence, the electrostatic deflector (7) is located at the corner of the vacuum chamber, and the quadrupole mass filter Device (8) has pole plate, has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com