Vinegar paste and preparation method thereof

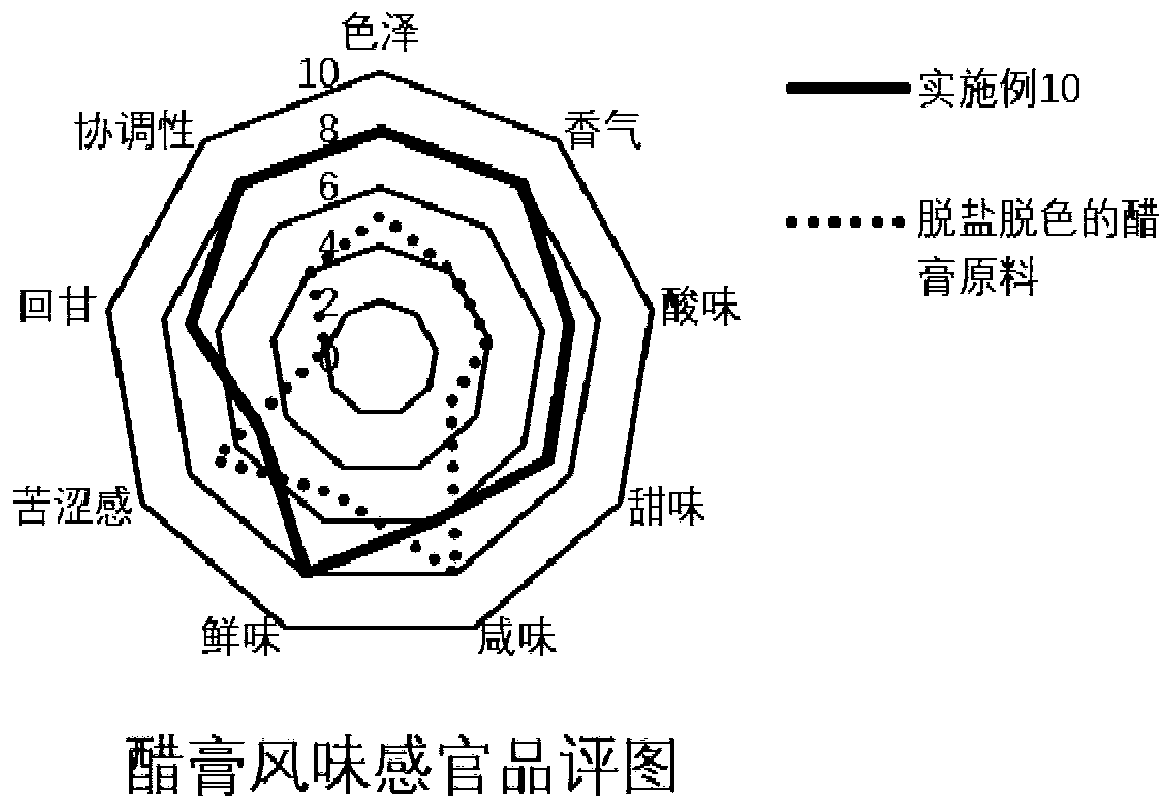

A production method and technology of vinegar ointment, applied in climate change adaptation, food science, etc., can solve problems such as resource waste, ineffective development and utilization, bitter taste, etc., and achieve comprehensive utilization, good health care function, and improved fragrance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

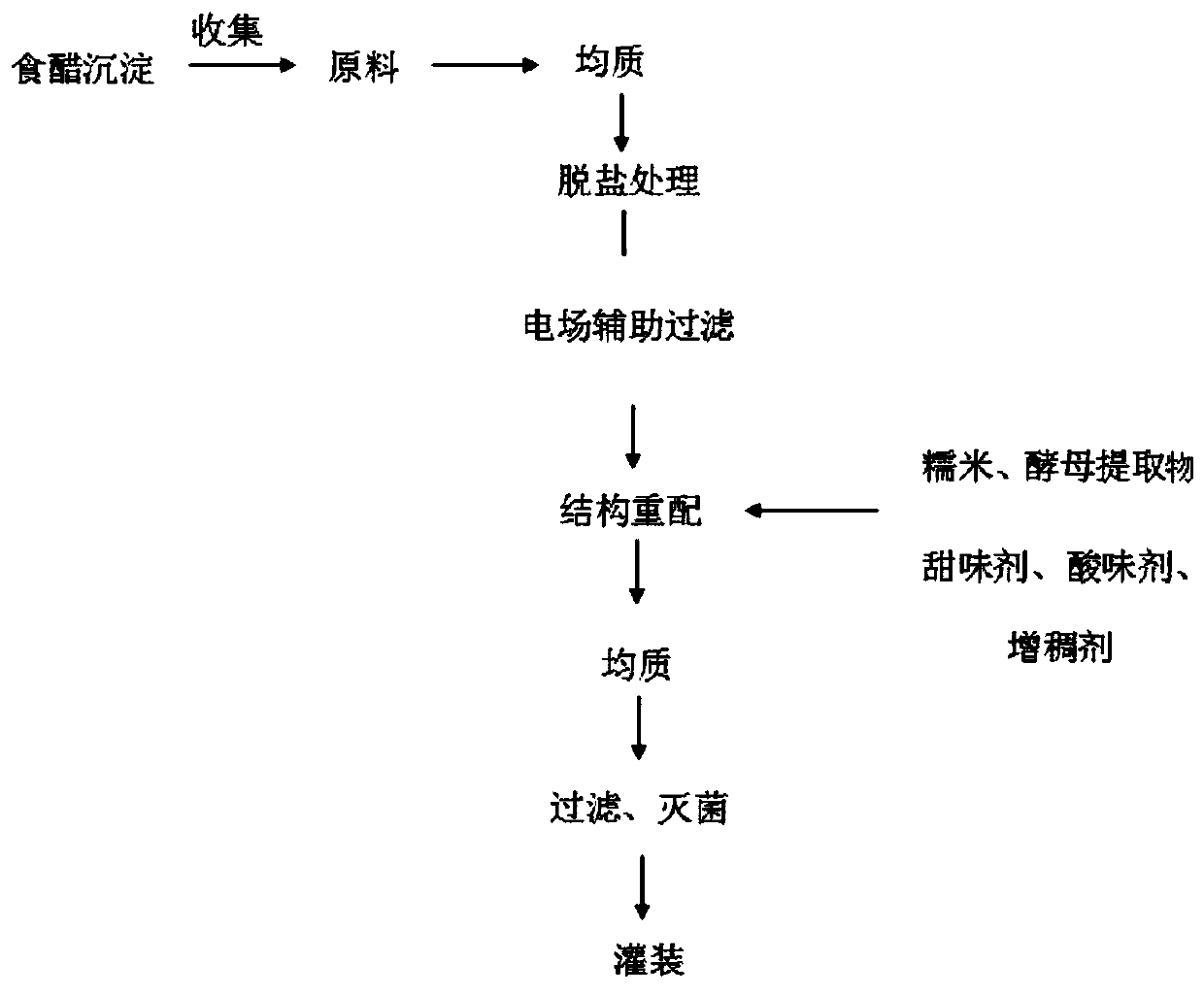

[0055] Embodiment 1 A kind of vinegar ointment and preparation method thereof

[0056] A kind of vinegar ointment, preparation method is as follows:

[0057] (1) Pretreatment of vinegar precipitation

[0058] Select vinegar that has been aged for more than 3 months, remove the vinegar liquid that is more than 2-3cm away from the vinegar sediment, collect the vinegar sediment at the bottom and a small amount of vinegar liquid in the storage tank, and heat-treat the vinegar liquid at 80°C for 10 minutes in advance. Stirring; after cooling to 30°C, grind through a colloid mill, the speed of the colloid mill is 8000r / min, and then pressurize for homogeneous crushing, the homogeneous pressure is 0.1MPa, the homogeneous temperature is 40°C, and the processing capacity is 10m 3 / h, the particle size of the precipitate after homogenization is about 1-30μm.

[0059] (2) Desalination and deastringency of vinegar precipitation

[0060] Take the homogenized raw material and let it pass...

Embodiment 2

[0072] Embodiment 2 A kind of vinegar ointment and its preparation

[0073] A kind of vinegar ointment, preparation method is as follows:

[0074] (1) Pretreatment of vinegar precipitation

[0075] Select aged vinegar to remove the vinegar liquid that is more than 2-3cm away from the vinegar sediment, collect the vinegar sediment at the bottom and a small amount of vinegar liquid in the storage tank, heat-treat the vinegar liquid at 80°C for 10 minutes in advance, and stir during the process; wait to cool to After 40°C, it is ground by a colloid mill. The speed of the colloid mill is 8000r / min, and then pressurized for homogeneous crushing. The homogeneous pressure is 0.1MPa, the homogeneous temperature is 40°C, and the processing capacity is 10m 3 / h.

[0076] (2) Desalination and deastringency of vinegar precipitation

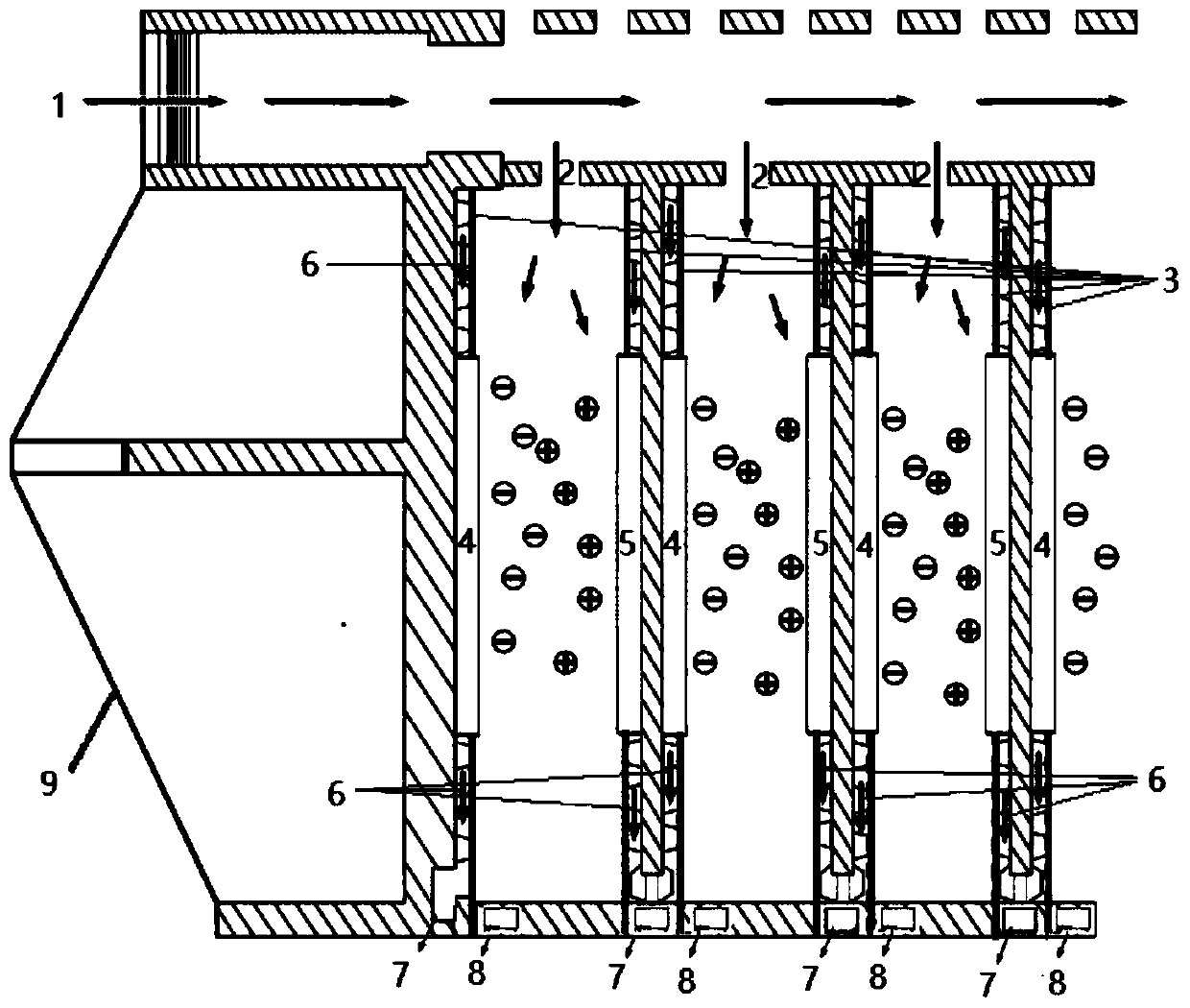

[0077] Take the homogenized raw material and let it pass through figure 2 The shown external electric field desalination equipment performs two desalina...

Embodiment 3

[0078] Embodiment 3 A kind of vinegar ointment and its preparation

[0079] A kind of vinegar ointment, preparation method is as follows:

[0080] (1) Pretreatment of vinegar precipitation

[0081] Select aged vinegar to remove the vinegar liquid that is more than 2-3cm away from the vinegar sediment, collect the vinegar sediment at the bottom and a small amount of vinegar liquid in the storage tank, heat-treat the vinegar liquid at 80°C for 10 minutes in advance, and stir during the process; wait to cool to After 40°C, it is ground by a colloid mill. The speed of the colloid mill is 8000r / min, and then pressurized for homogeneous crushing. The homogeneous pressure is 0.1MPa, the homogeneous temperature is 40°C, and the processing capacity is 10m 3 / h.

[0082] (2) Desalination and deastringency of vinegar precipitation

[0083] Take the homogenized raw material and make it go through the desalination equipment with external electric field for two desalination treatments. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com