Process for producing high solids colloidal silica

A technology of colloidal silicon dioxide and colloid, which is applied in the direction of silicon dioxide, silicon oxide, chemical instruments and methods, etc., and can solve problems such as damage to the stability of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] The foregoing may be better understood with reference to the following examples, which are shown for purposes of illustration and not intended to limit the scope of the invention.

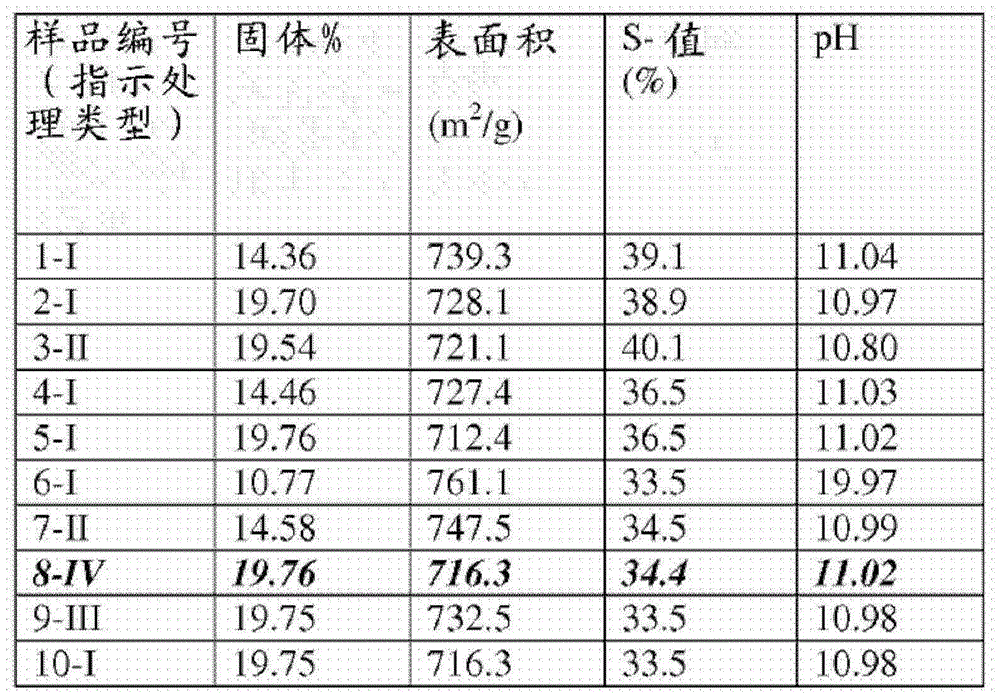

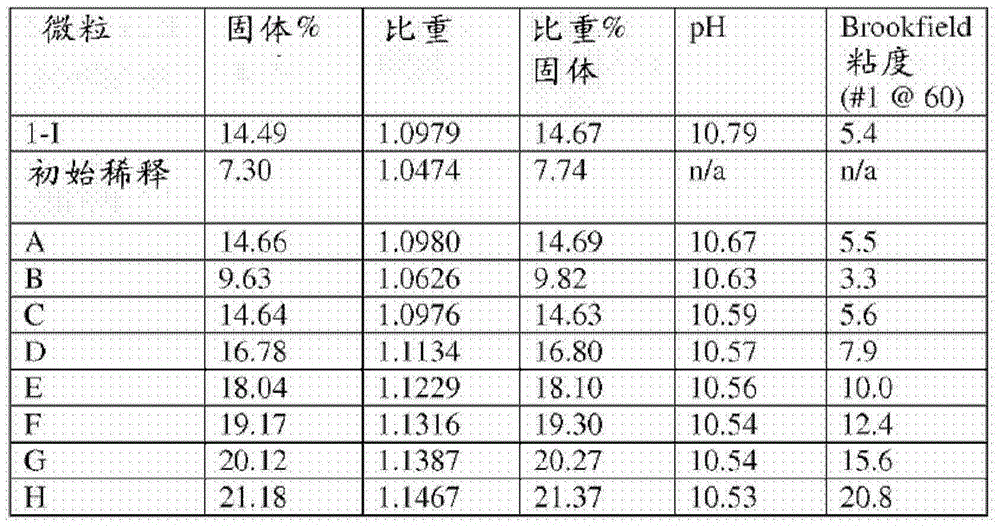

[0051] Various colloidal silica samples were produced according to the resin-based formation process. Various properties of the samples were measured. S-value, surface area, and % solids are proxies used to predict the effectiveness of a sample in industrial applications. Samples were derived from commercially available colloidal silica (POSITEK 8699, Nalco Corporation, Naperville, IL) and were modified according to one of the following processing schemes.

[0052] I) Unmodified

[0053] II) Add cationic resin to reduce conductivity

[0054] III) Apply ultrafiltration

[0055] IV) Di-filtration is applied.

[0056] Properties of these samples are listed below.

[0057]Table 1

[0058]

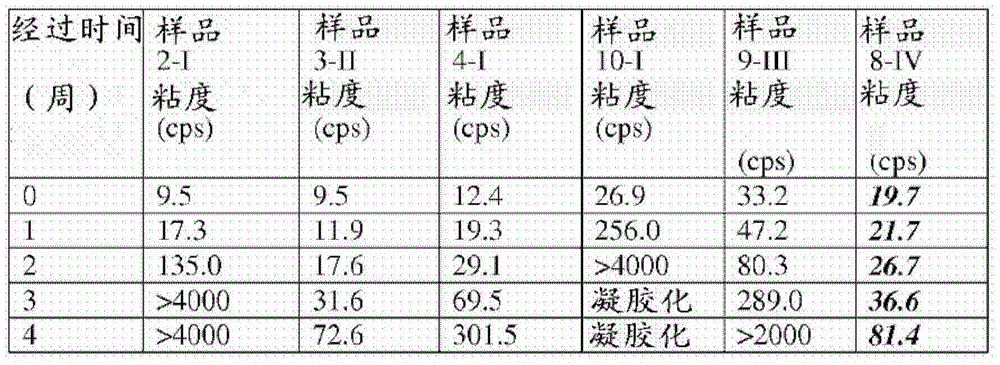

[0059] The stability of these colloids is as follows:

[0060] Table 2

[0061]

[0062] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com