Welding gun moving auxiliary equipment

A mobile auxiliary and equipment technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of conveying welding wire, affecting safety, increasing the difficulty of welding wire regulation, etc., to achieve the effect of convenient use and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

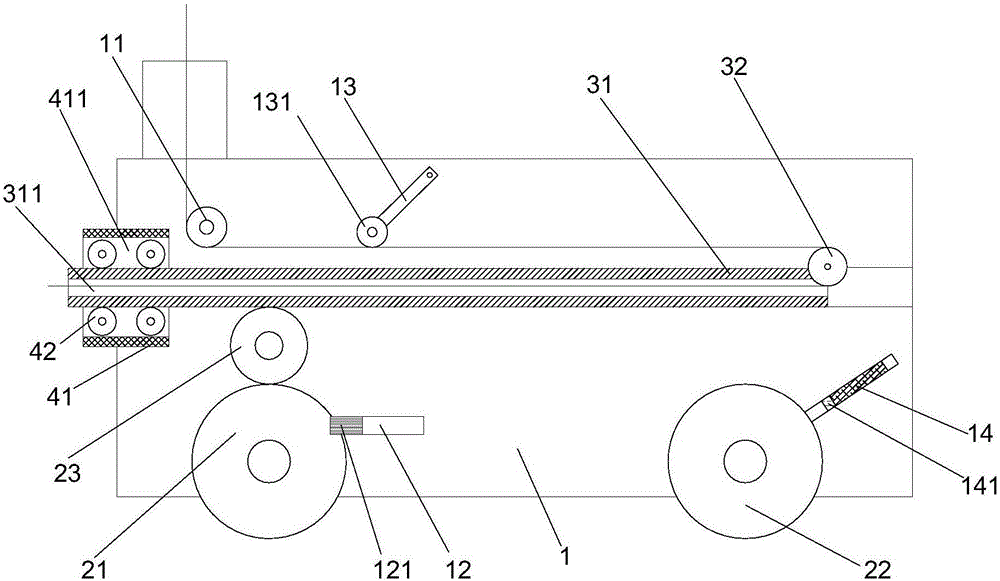

[0016] refer to figure 1 As shown, a welding torch mobile auxiliary device proposed by the present invention includes a mounting frame 1, a roller set, a wire guide mechanism and a positioning mechanism;

[0017] The roller set includes a first moving wheel 21, a second moving wheel 22 and a driving wheel 23, the first moving wheel 21 and the second moving wheel 22 are installed on the lower part of the mounting frame 1, and the driving wheel 23 and the axis of the first moving wheel 21 are parallel to each other , the driving wheel 23 abuts against the first moving wheel 21, and the outer diameter of the driving wheel 23 is half of the outer diameter of the first moving wheel 21;

[0018] The guide wire mechanism includes a moving rod 31 and a first guide wheel 32. The moving rod 31 is movably mounted on the mounting frame 1. The moving direction of the moving rod 31 is its length direction. The longitudinal direction of the moving rod 31 is perpendicular to the axial directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com