High Efficiency Pantograph

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

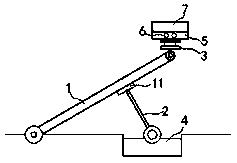

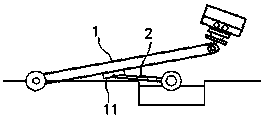

[0021] exist Figure 1 to Figure 4 In the shown embodiment, the high-efficiency pantograph includes a connecting rod 1 and a strut 2,

[0022] One end of the connecting rod 1 is hingedly mounted on the top plate of the train, and the other end of the connecting rod 1 is fixedly equipped with a telescopic arm 3, and the telescopic arm 3 is controlled to expand and contract by the electrical system;

[0023] A slider 11 is installed on the connecting rod 1, and the slider 11 can reciprocate and translate along the axis direction of the connecting rod 1; one end of the rod 2 is hinged on the slider 11, and the other end is installed on the rotating motor 4 On the drive shaft, the pole 2 can rotate synchronously with the drive shaft;

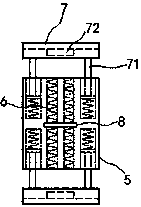

[0024] A slide plate 5 is fixedly installed at the end of the telescopic arm 3, and an induction solenoid 6 is embedded inside the slide plate 5, and the axis of the induction solenoid 6 is perpendicular to the contact line on the catenary;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com