Flexible wrapping machine

A flexible and wrapping machine technology, which is applied in the field of flexible wrapping machines, can solve the problems of low matching precision of mechanical joints, inaccurate sealing of boxes, and dense indentation layout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

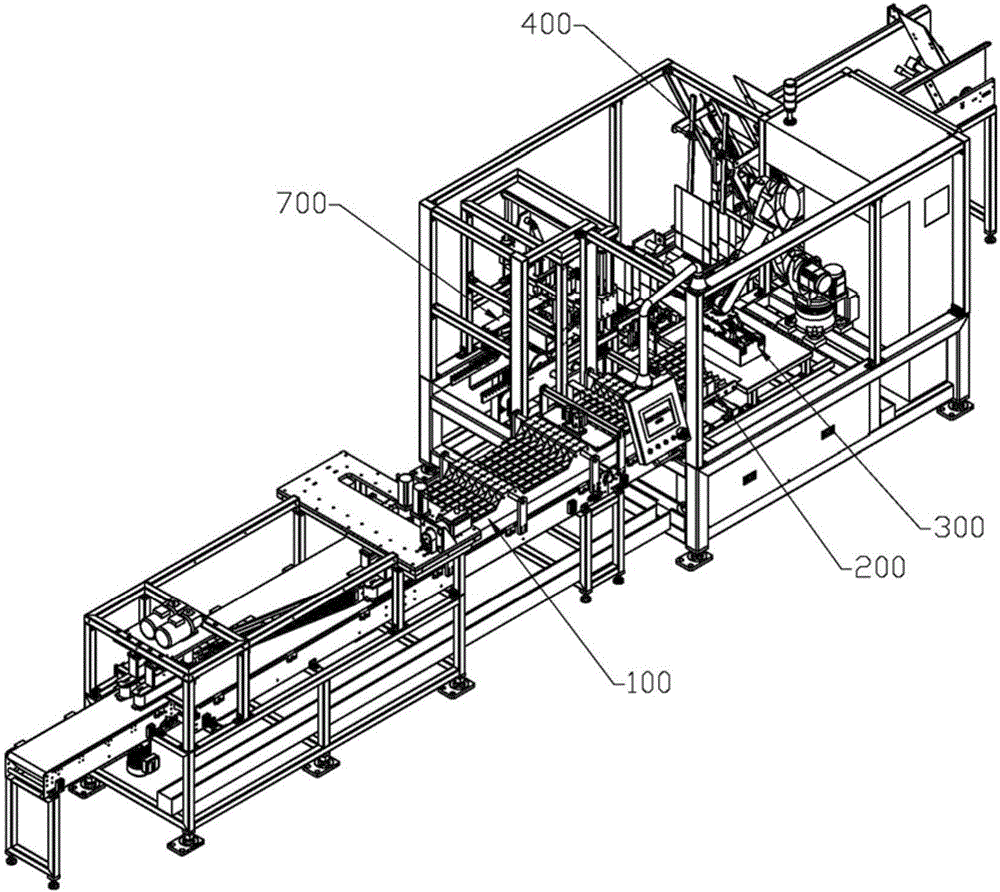

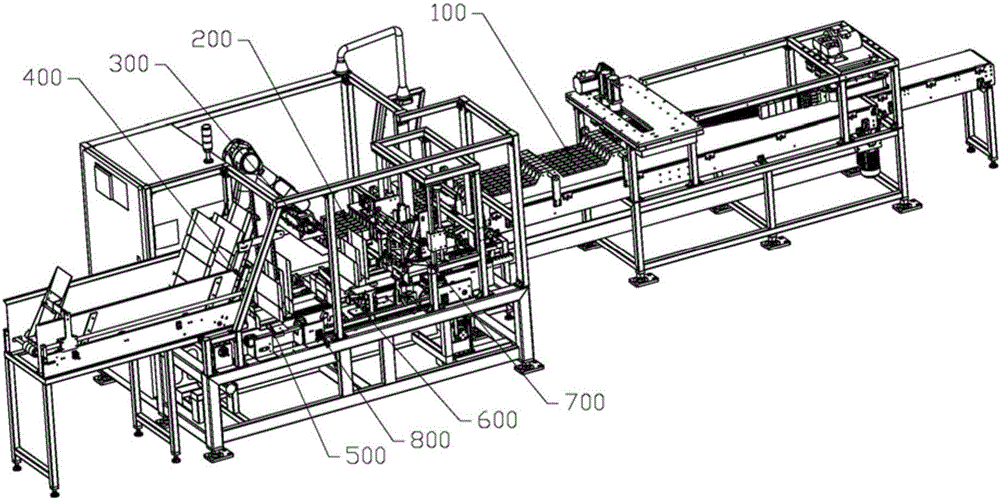

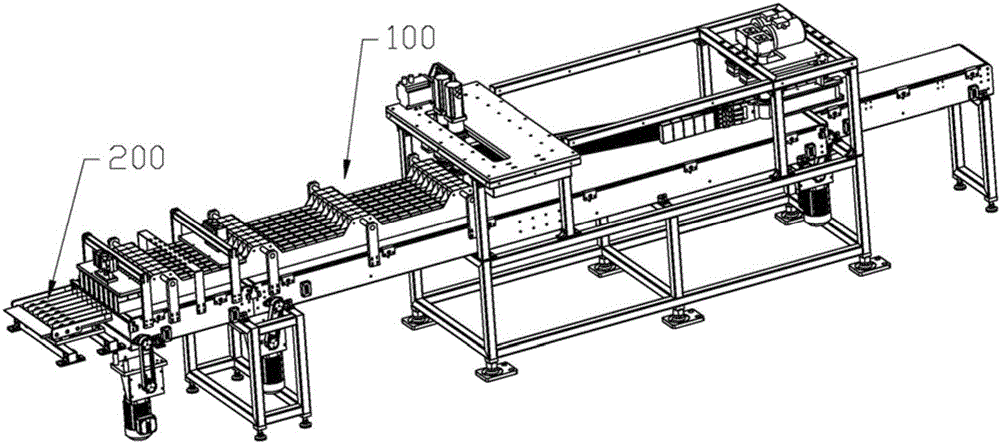

[0080] Such as Figure 1-20 Shown: a flexible wrapping machine, including a lane-splitting conveying mechanism 100, the lane-separating conveying mechanism 100 integrates the flexible multi-standard integration mechanism 200 that transports the milk pack to its tail end into a milk pack unit, and the milk pack unit is controlled by a robot tool fixture 300 Grab to the packing box at packing station 600 on the packing case conveying line for packing, after packing, the packing case will be dispensed by glue dispenser on the way to packing station 700; sealing station The piston rod of the top forming cylinder 702 on the 700 can simultaneously complete the pressing and forming of the top front and top hem of the packaging box in one stretch, and the bottom side seal turning cylinder 728 at the sealing station 700 can drive the bottom side seal The overtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com