A solar tube palletizing device

A stacking device, solar technology, applied in transportation and packaging, stacking of objects, etc., can solve the problems of high cost, waste of labor, low work efficiency, etc., and achieve the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

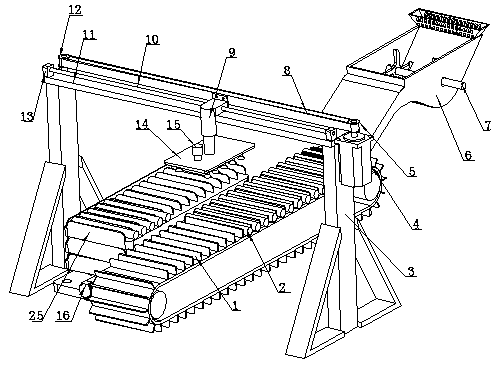

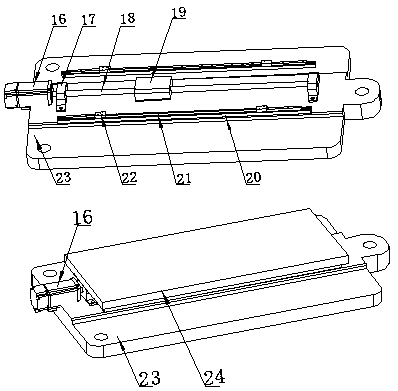

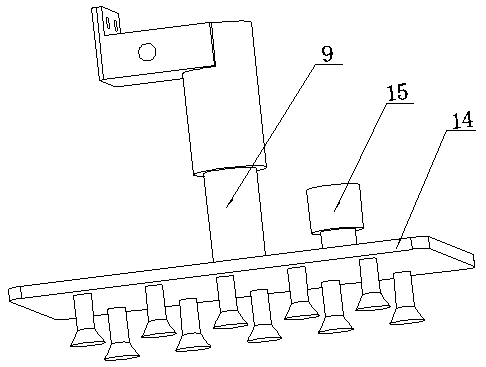

[0010] A solar tube stacking device is composed of a conveyor belt 1, a solar tube 2, a device bracket 3, a stepping motor Ⅰ 4, a synchronous pulley driving wheel 5, a conveying groove 6, a paddle wheel 7, a synchronous belt 8, a lifting cylinder 9, Cylindrical guide rail 10, beam 11, synchronous pulley driven wheel 12, cylindrical guide rail support 13, suction cup 14, suction cup cylinder 15, stepper motor II 16, link shaft seat 17, horizontal screw 18, nut block 19, track seat 20, Slide rail 21, slide block 22, mounting seat plate 23, bearing plate 24 form. It is characterized in that: the conveyor belt 1 is installed in the middle of the device bracket 3, the delivery trough 6 is installed above one end of the conveyor belt 1, the paddle wheel 7 is installed in the delivery trough 6, the device bracket 3 is placed on both sides of the moving line of the suction cup 14, and the beam 11 is placed on the On the top of the device support 3, a column guide rail 10 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com