Clothes dryer and control method thereof

A dryer and air duct technology, applied in household dryers, textiles and papermaking, washing devices, etc., can solve problems such as the loss of clothes dryers and other indoor components, achieve suitable promotion and use, eliminate peculiar smells, and have remarkable effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

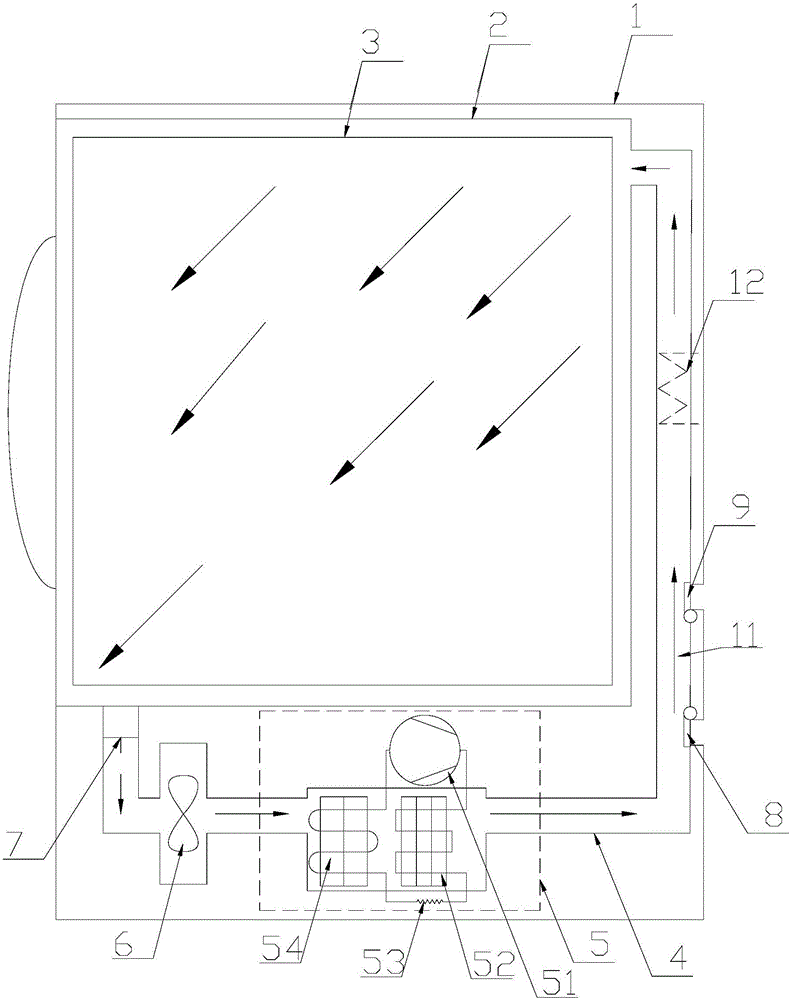

[0047] Such as figure 2 As shown, in this embodiment, the air intake door 9 and the air outlet door 8 divide the circulating air path into the first air path 10 and the second air path 11; the evaporator 54 and the condenser 52 are located at the same In the first air passage 10 , and the evaporator 54 is arranged away from the air outlet damper 8 relative to the condenser 52 .

[0048] In this embodiment, the second air path 11 is provided with an openable and closable partition, so that the external airflow flowing into the circulating air path from the air inlet door 9 all flows along the first air path 10 to the air outlet door. 8, instead of flowing through the second air path 11 to the air outlet damper 8, it is ensured that the inhaled external air is dehumidified by the heat pump system, and the dehumidification efficiency of the clothes dryer is improved.

[0049] Such as figure 2 As shown, in this embodiment, the air inlet door 9 and the air outlet door 8 are hin...

Embodiment 2

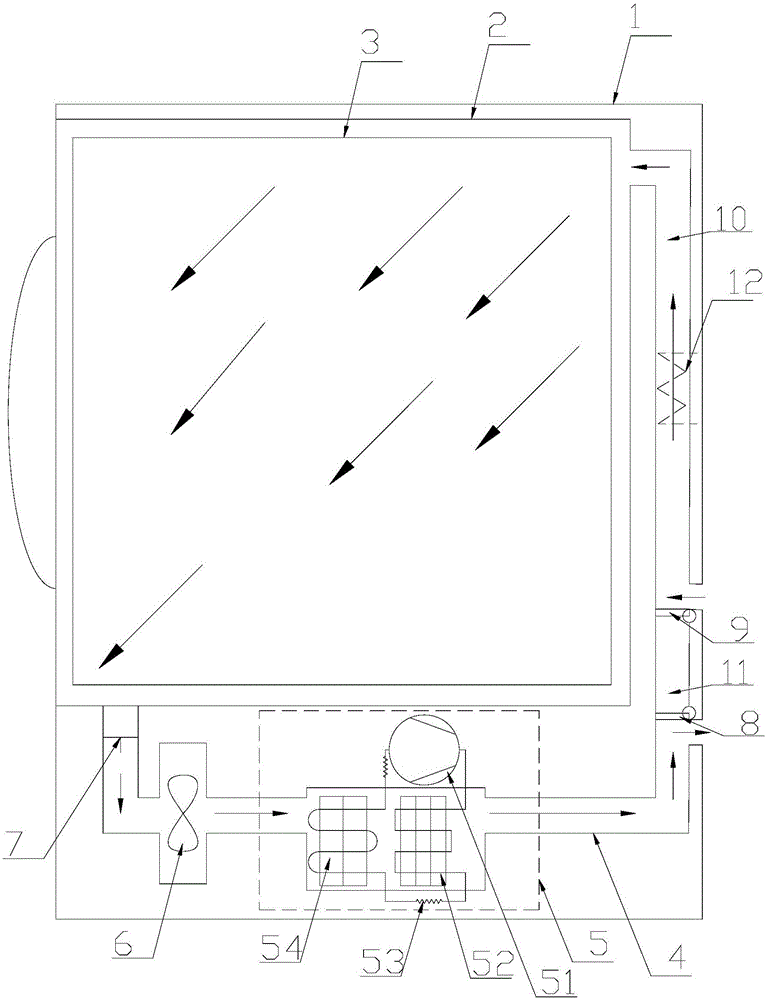

[0054] In this embodiment, the air inlet door 9 and the air outlet door 8 are both arranged at the rear side of the clothes dryer.

[0055] Such as image 3 As shown, in this embodiment, the air inlet door 9 and the air outlet door 8 are both arranged in the drying air duct 4 between the condenser 52 and the air inlet of the outer cylinder 2, and the air inlet door 9 is relatively air outlet. The damper 8 is located away from the condenser 52 . Thus, the external air flows into the drying air duct 4 from the air inlet door 9 at the rear of the dryer, then passes through the outer cylinder 2, the evaporator 54, and the condenser 52 in sequence, and finally reaches the outlet air door at the rear of the dryer. 8 flow out to achieve dehumidification of the external airflow. At the same time, during the dehumidification process, a flowing airflow is formed in the outer cylinder to achieve the effect of eliminating peculiar smell inside the outer cylinder of the clothes dryer.

...

Embodiment 3

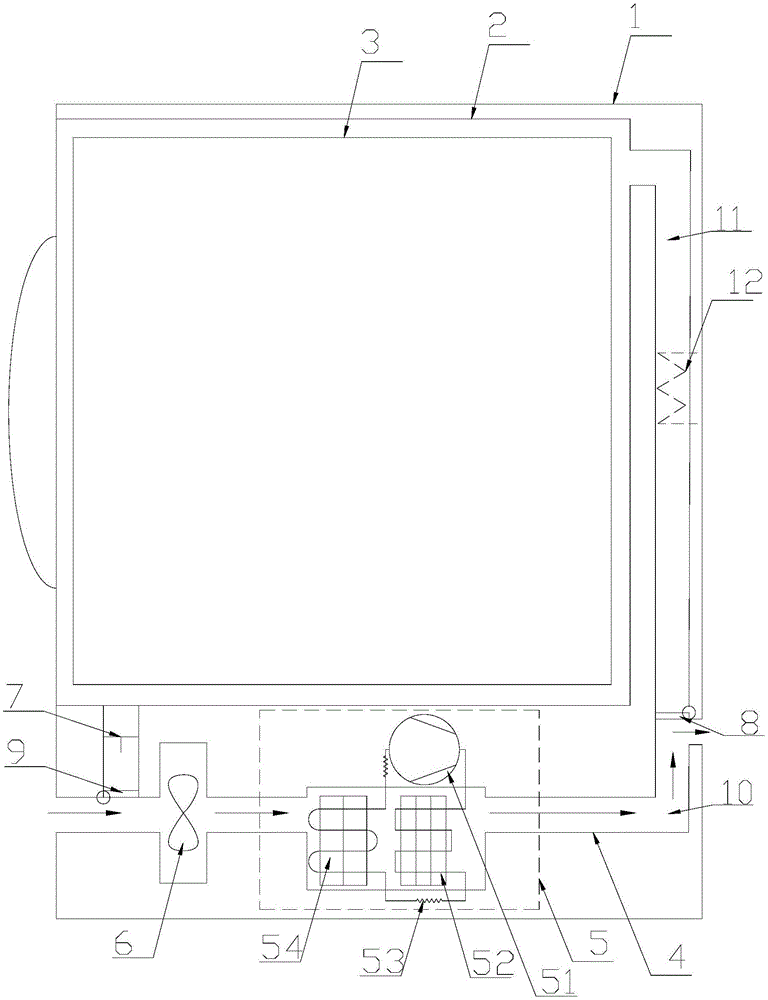

[0058] In this embodiment, the air inlet door 9 is arranged at the front side of the clothes dryer, and the air outlet door 8 is arranged at the back side of the clothes dryer.

[0059] Such as image 3 As shown, in this embodiment, the air inlet damper 9 is arranged in the drying air duct 4 between the air outlet of the outer cylinder 2 and the evaporator 54, and the air outlet damper 8 is arranged at the inlet of the condenser 52 and the outer cylinder 2. In the drying air duct 4 between the tuyere. Thus, the external air flows into the drying air duct 4 from the air inlet door 9 at the front of the clothes dryer, then passes through the evaporator 54 and the condenser 52 in sequence, and finally flows out to the air outlet door 8 at the rear of the clothes dryer, so as to Realize the dehumidification treatment of the external airflow.

[0060] Through the above setting, the external air flowing into the dryer does not pass through the outer cylinder, and is directly disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com