Valve disk

A technology of valve disc and valve body, which is applied in the direction of lifting valve, valve device, engine components, etc., can solve the problems of large flow resistance and eddy current, and achieve the effect of reducing eddy current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

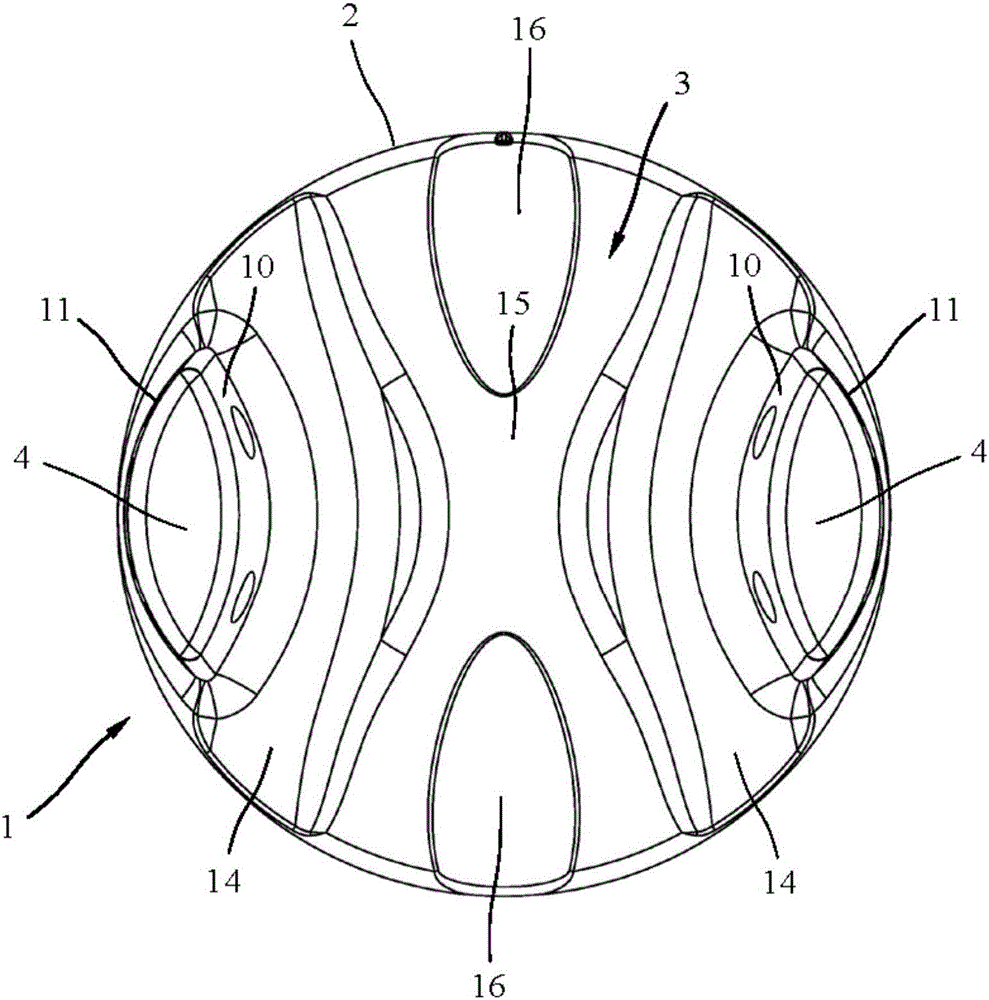

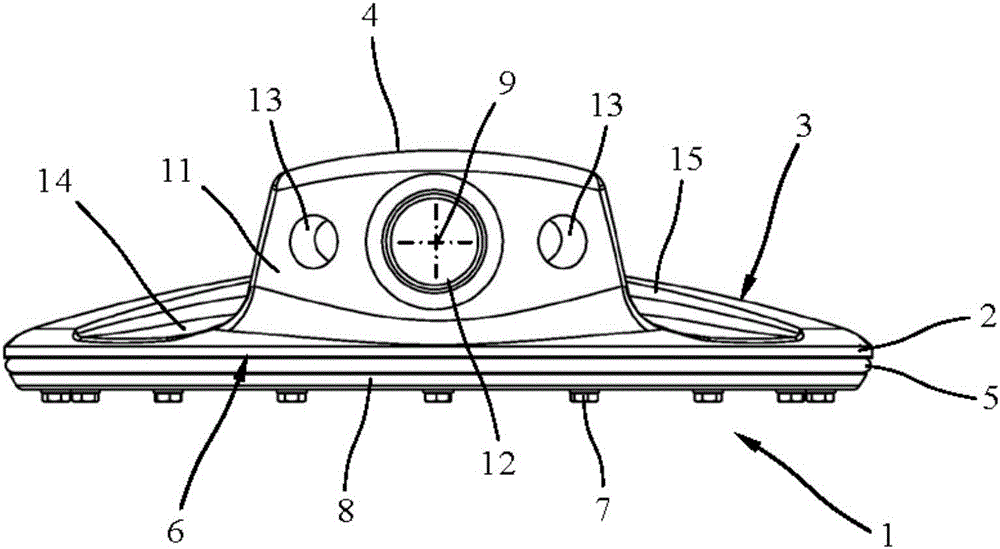

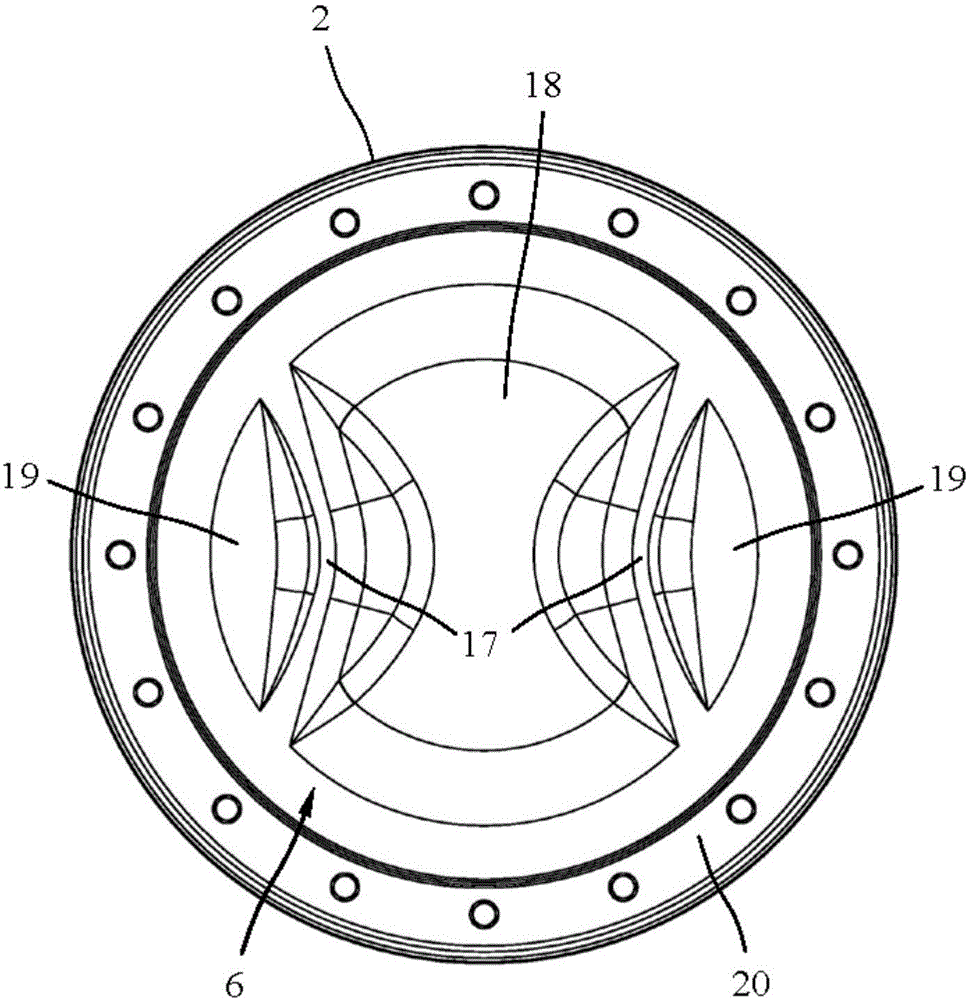

[0020] exist figure 1 top view of and figure 2 The valve disc 1 of the shut-off valve is shown in the side view. The valve disk 1 shown comprises a disk-shaped valve body part 2 which has on its outer side two hubs 4 protruding relative to the front side 3 of the valve body part 2 and facing each other. The valve disc 1 is also included in the figure 2 An annular or disk-shaped seal 5, which can be seen in the figure, and a fastening ring 8 releasably fastened on the back side 6 of the valve body 2 by means of a screw 7, by which the seal 5 is tightly Fixed on the valve body part 2. The valve body 2 of the valve disk 1 is mounted in a known manner in a housing interior in which the circular through-opening is provided so as to be pivotable about a rotational axis 9 extending perpendicularly to the central axis of the through-opening.

[0021] Such as figure 1 It is known that the valve body 2 has, on its front side 3 arranged between the hubs 4 , a contour which will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com