Steam superheater

A superheater and steam technology, which is applied in the field of waste heat recovery equipment, can solve the problems of high cost, large floor space, and inconvenient cleaning of steam superheaters, and achieve the effects of reducing deformation and swing, ensuring heat exchange, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

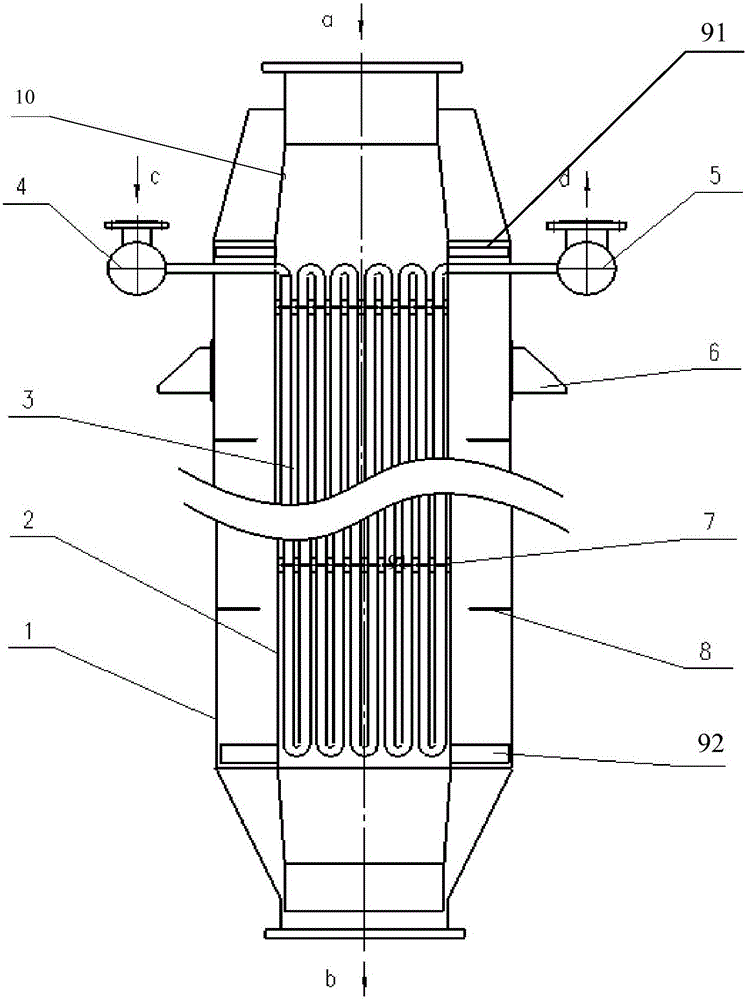

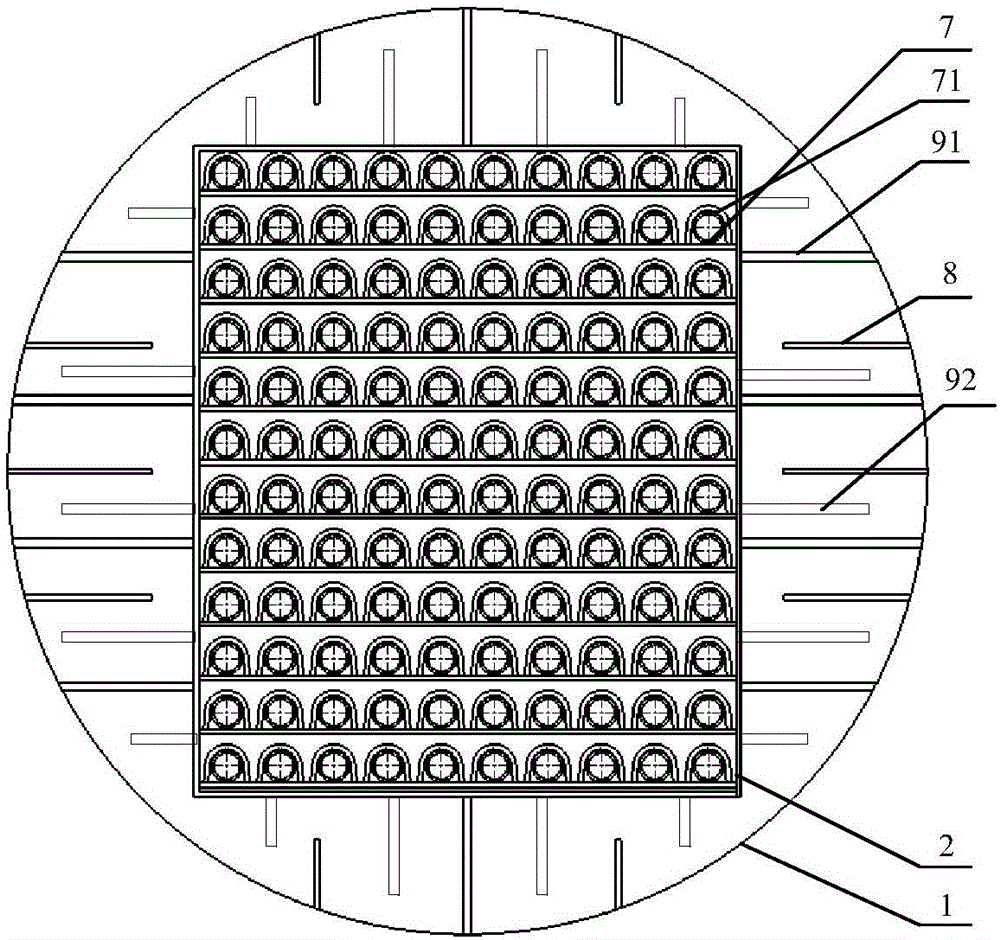

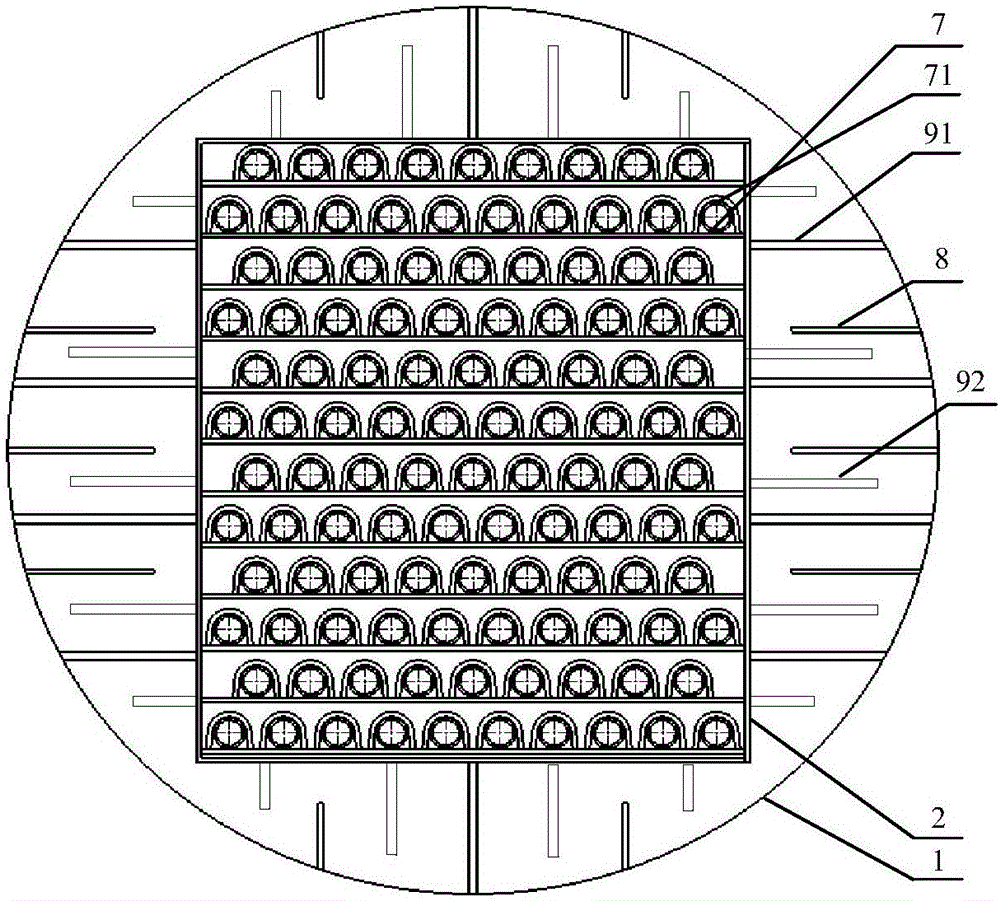

[0022] figure 1 The front view of the steam superheater provided by the present invention, figure 2 For square heat exchange tube panels figure 1 top view, image 3 For triangular heat exchange tube panels figure 1 top view, such as figure 1 , figure 2 and image 3 As shown, the steam superheater of this embodiment may include: an outer column body 1, an inner square body 2, limiting plates (91 and 92), heat exchange tube panels 3, an inlet header 4, and an outlet header 5; Wherein the outer cylinder body 1 is sleeved outside the inner square cylinder body 2, the annular space formed between the outer cylinder body 1 and the inner square cylinder body 2 is provided with limiting plates (91 and 92), and the distance from the inner square cylinder body 2 The nearest layer of limiting plate 91 of the fluid inlet a is connected to the outer cylinder body 1 and the inner square cylinder body 2, and the other layers of limiting plates 92 are connected to the inner square cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com