Method for lowering abrasion of boiler heating surface

A technology for heating surfaces and boilers, applied in the direction of coating, etc., can solve problems such as impact, and achieve the effects of high cost, increased safety performance, and improved unit efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

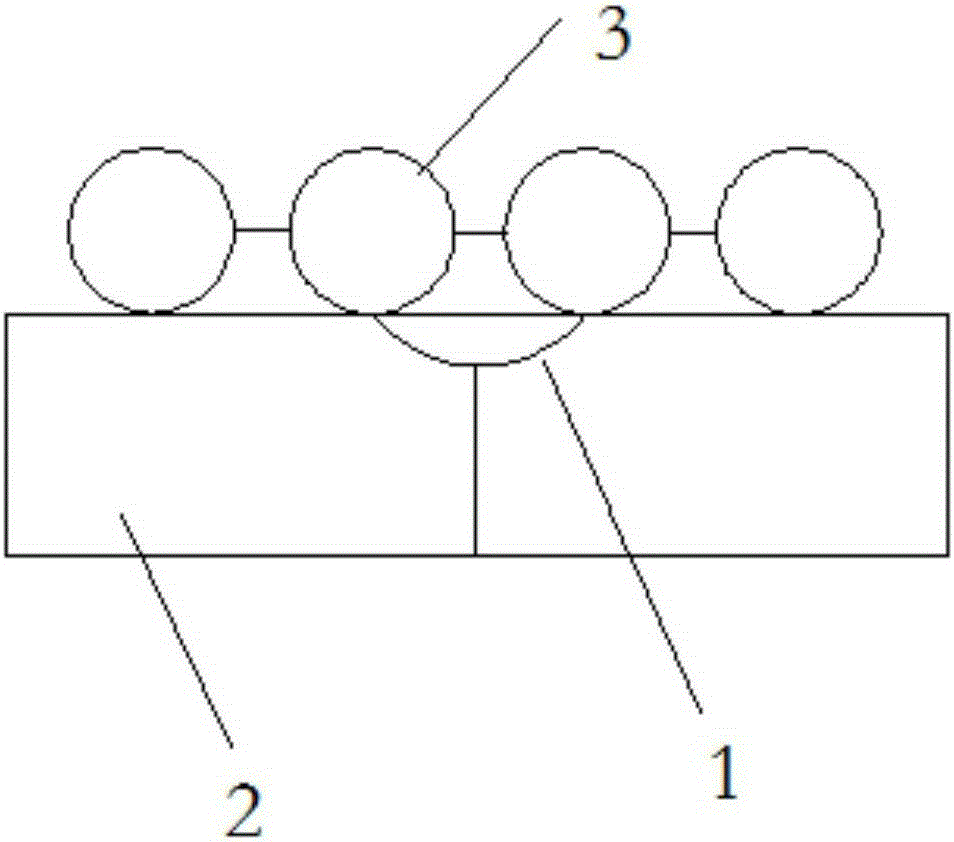

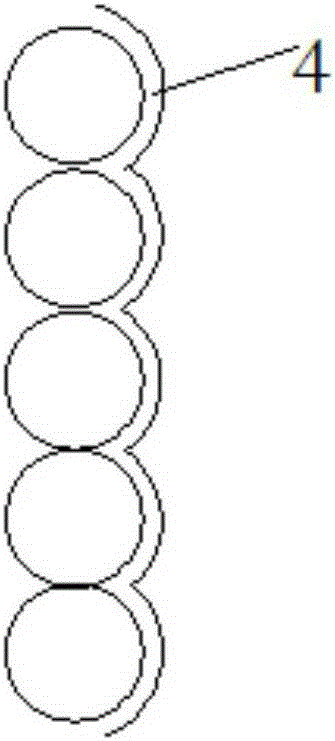

[0021] The company is a 2*1000MW ultra-supercritical pressure once-through boiler, and the water-cooled wall adopts a spiral surrounding structure. The number of tubes in the spiral coil is 716, the diameter is Φ38.1*7, the material is T23, the material of the inclined furnace bottom is 15CrMo, and the inclination angle is 26.2103°. At an elevation of 69225mm, the spiral coil passes through the middle of the furnace. The header is converted into a vertical pipe circle, and the spiral pipe circle is 1.2 circles calculated from the inflection point of the cold ash hopper to the exit of the spiral pipe circle. Since the beginning of August 2009, the water-cooled wall tubes of units 1 and 2 have exploded 86 times.

[0022] At the connection between the upper part of the 4.5-meter water seal and the water-cooled wall header, an anti-wear cover is installed, and metal spraying is used to prevent wear at the part where the ash and slag of the water-cooled wall tube below 22 meters is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap