Special detection tool for template

A formwork and testing device technology, applied in the field of special testing devices for formwork verticality, can solve the problems of inability to measure the verticality of formwork projects, a large number of personnel, and complicated operations, so as to solve the problem of verticality verification of formwork, improve project quality, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

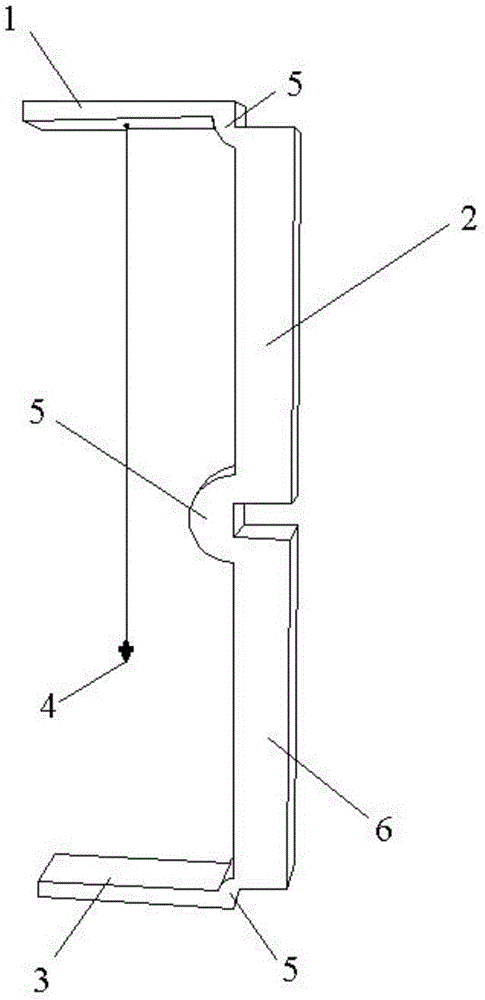

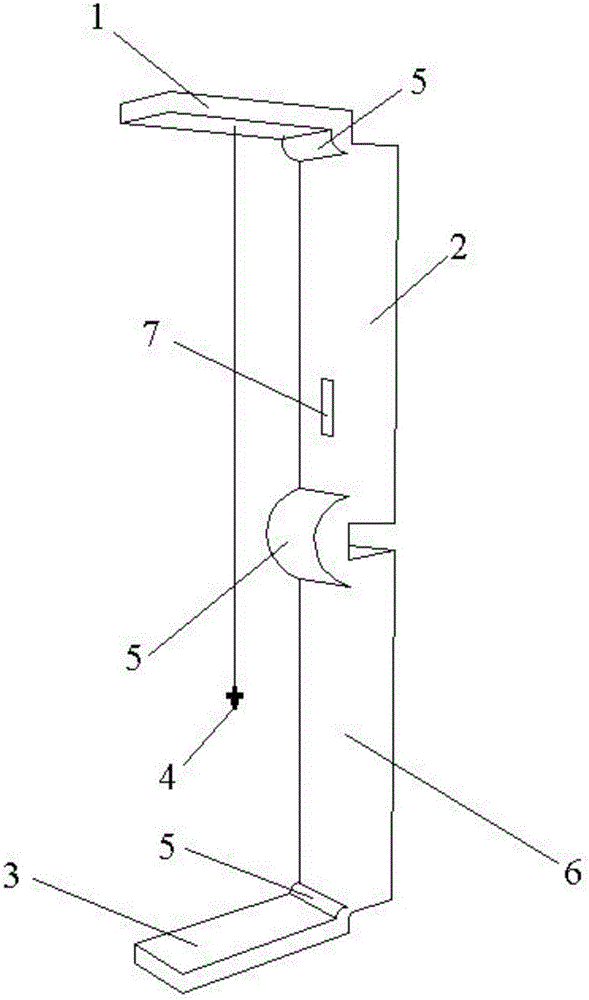

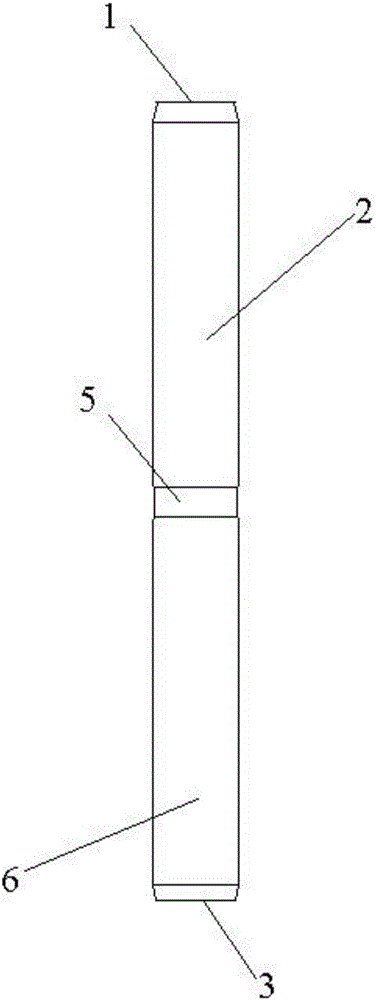

[0015] Figure 1-Figure 3 The structure of the present invention is shown, and it can be seen that the main body of the present invention is the aluminum alloy rectangular tube commonly used in construction engineering. The present invention needs to use four sections of rectangular tubes, that is, the top horizontal rectangular tube 1 above, and the bottom horizontal rectangular tube below. The pipe 3, and the upper vertical rectangular pipe 2 and the lower vertical rectangular pipe 6 between the two, are provided with a wire hammer 4 below the top horizontal rectangular pipe 1, and the wire hammer 4 is suspended above the bottom horizontal rectangular pipe 3 , and roughly parallel to the vertical rectangular tubes at both ends.

[0016] The top horizontal moment tube 1 is connected with the upper vertical moment tube 2 through the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com