System and method for automatically measuring total solid content

A technology of automatic measurement of dissolved total solids, applied in the direction of weighing by removing certain components, can solve the problems of human error system, cumbersome operation process, errors, etc., and achieve the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

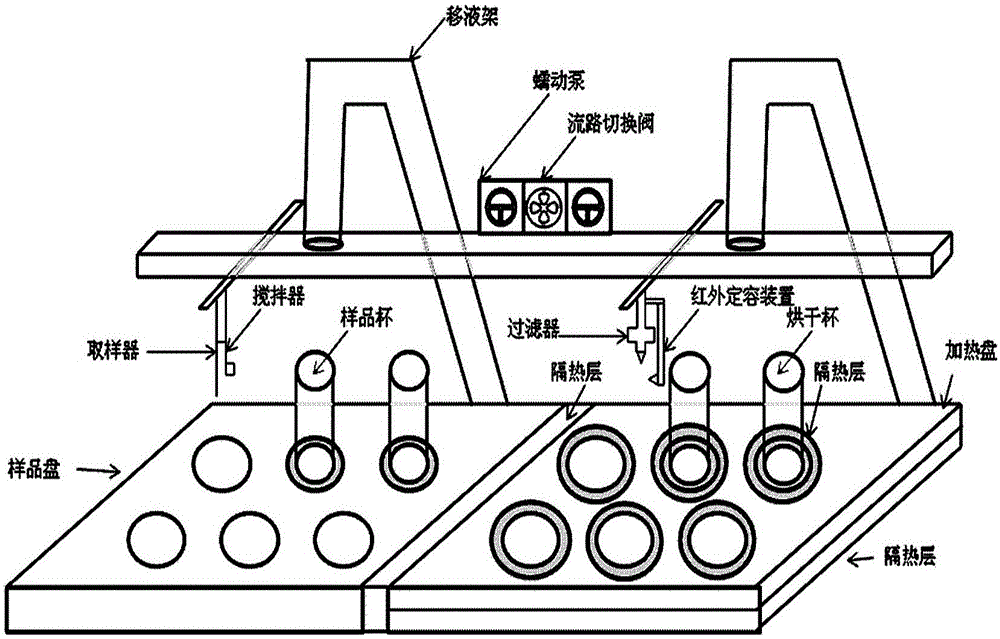

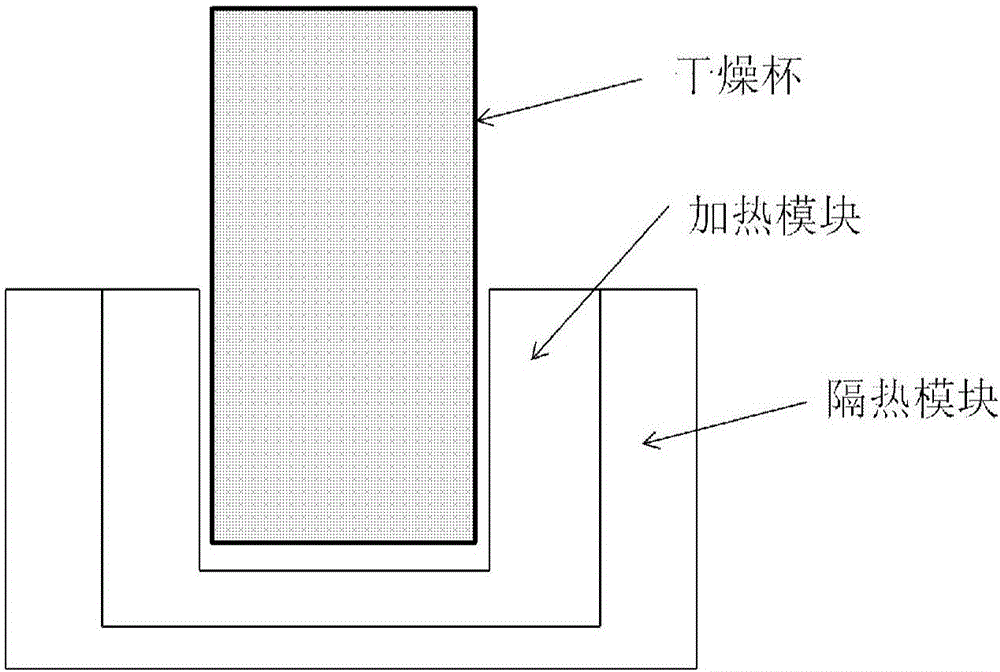

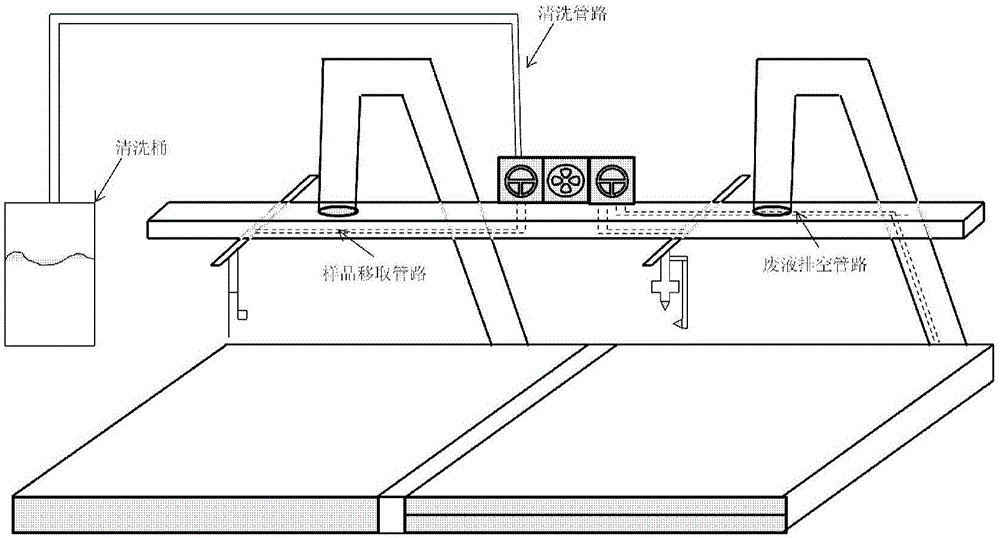

[0026] The automatic measurement system of the present invention can replace the traditional manual process of pipetting, filtering and drying the sample solution containing total soluble solids, and the whole process is automatically operated by software, and the drying cup after drying can be directly used for constant weight weighing Measurement. During operation, first use deionized water to self-clean the system pipeline, then stir the water sample and wait for it to stand still, quantitatively pipette the water sample, filter it through the filtration system, and dry the filtered water sample in a drying cup.

[0027] More specifically, the present invention discloses an automatic measurement system for total dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com