Prediction method and prediction system of nitrogen oxide concentration in coking flue gas

A technology of nitrogen oxides and prediction methods, applied in prediction, neural learning methods, physical realization, etc., can solve problems such as many uncertain factors, poor effects, and inability to perform quantitative calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

[0038] The embodiments of the present invention can be applied to coking plants, which include induced draft fans, waste heat recovery boilers, booster fans, desulfurization towers, denitrification towers, ammonium sulfate circulation tanks, solid-liquid separators, urea dissolution tanks, pipelines and auxiliary pumps and other related equipment , process parameter detection device, process parameter adjustment device, DCS system (Distributed Control System, distributed control system or distributed control system, is a computer control system), etc.

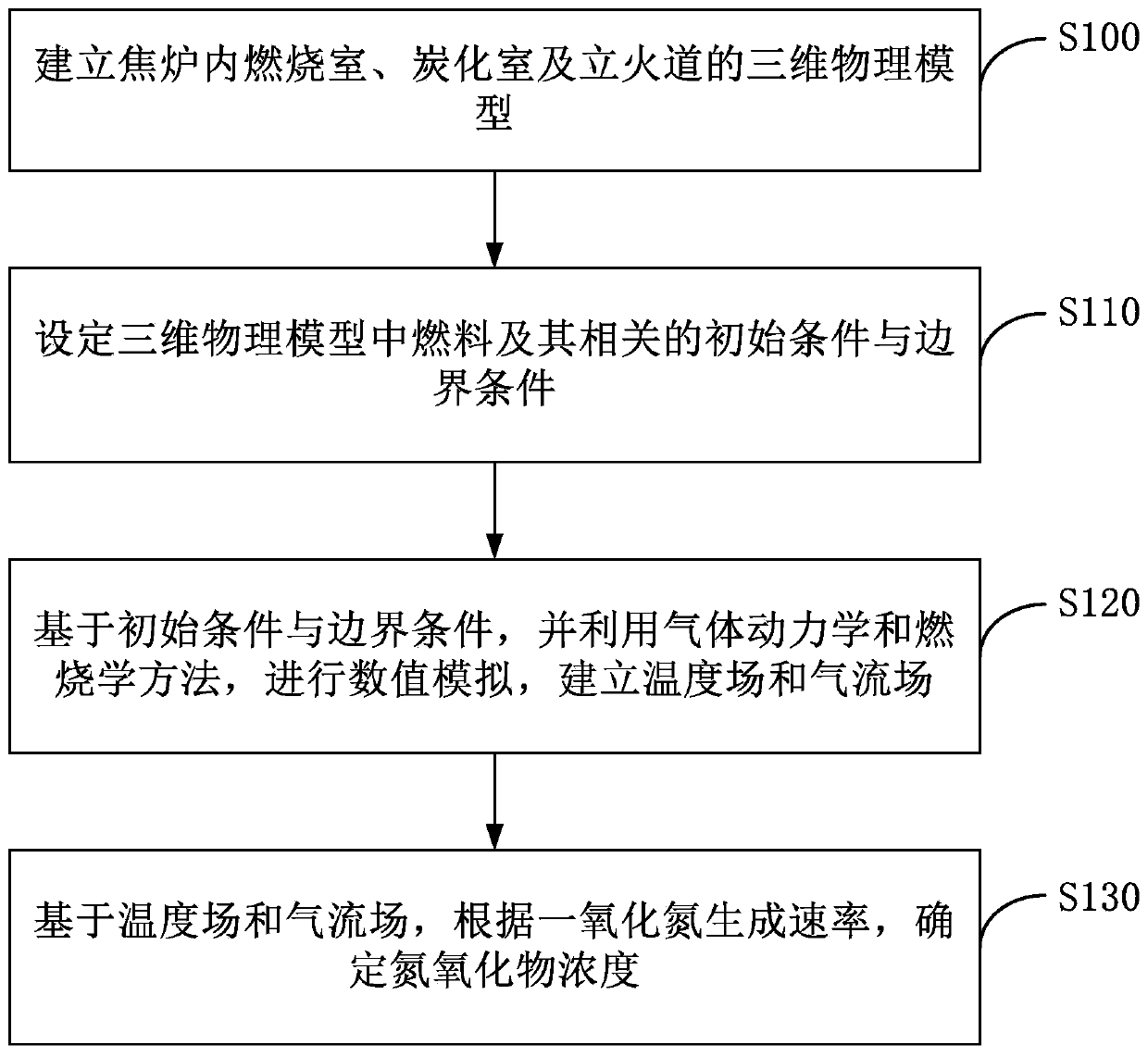

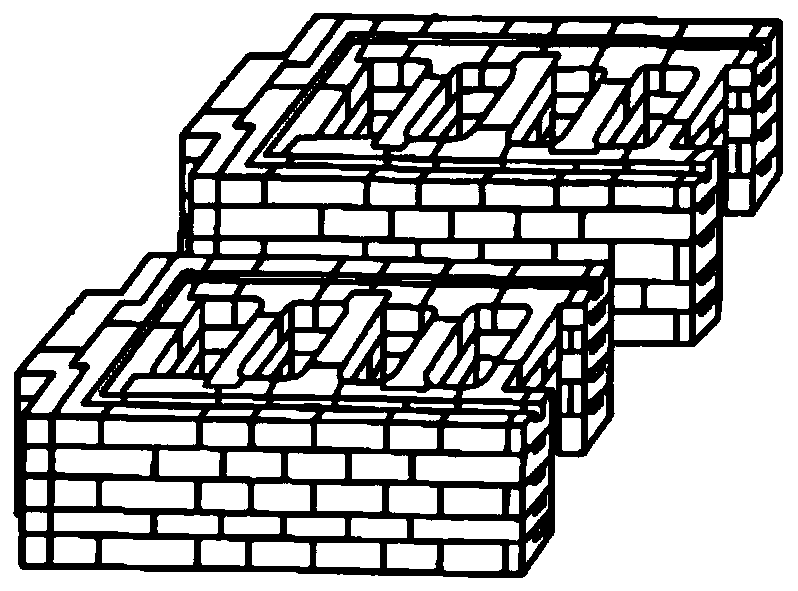

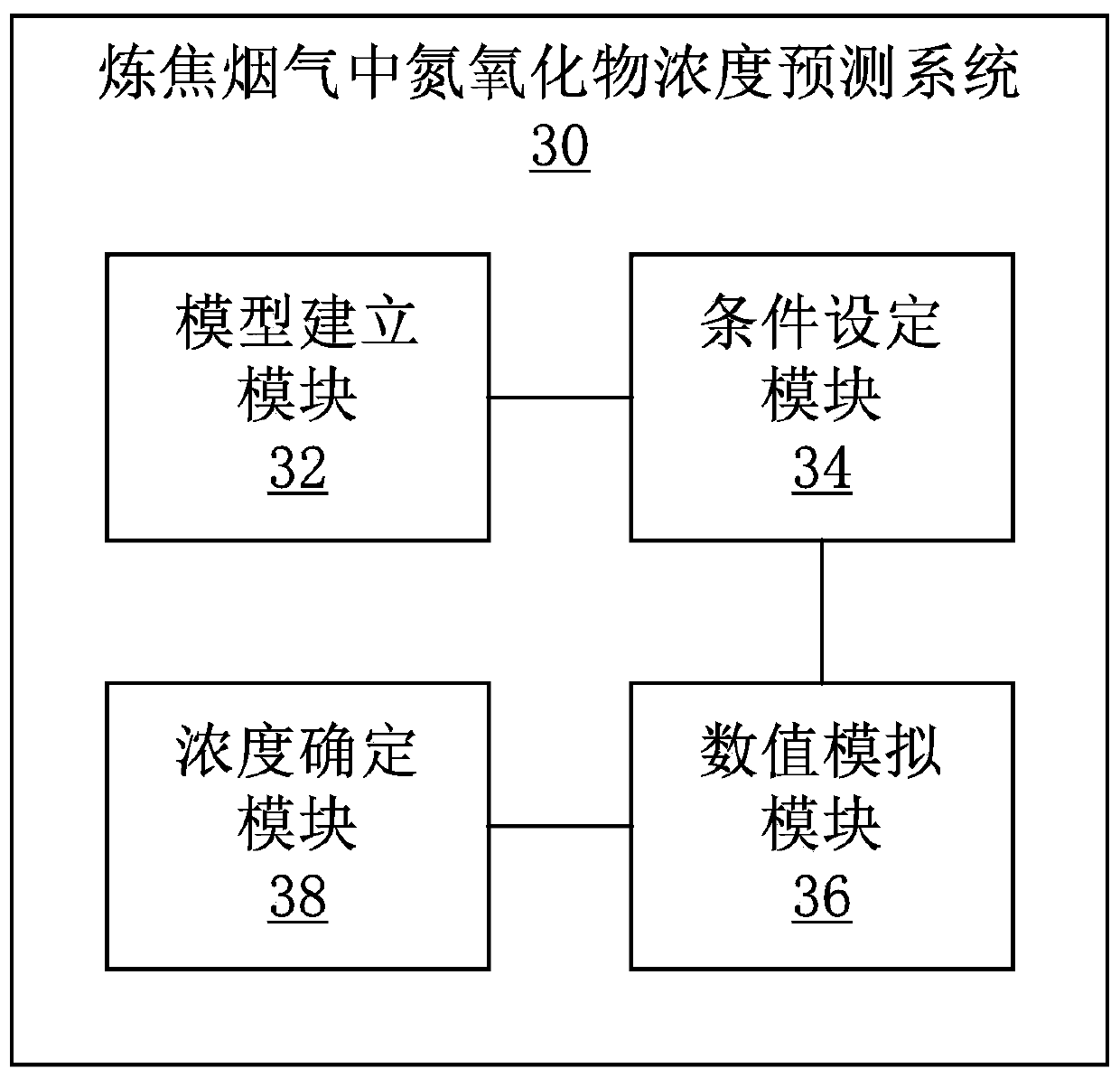

[0039] In order to improve the accuracy of predicting the concentration of nitrogen oxides,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com